Tool for overall assembling welding of engine outer ring assembly

A technology for assembling welding and engines, which is applied in the direction of welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of affecting the processing progress, high manufacturing cost, and heavy calibration workload, and achieve accurate, fast and stable clamping and positioning, and meet multiple requirements. The effect of application requirements and reduction of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

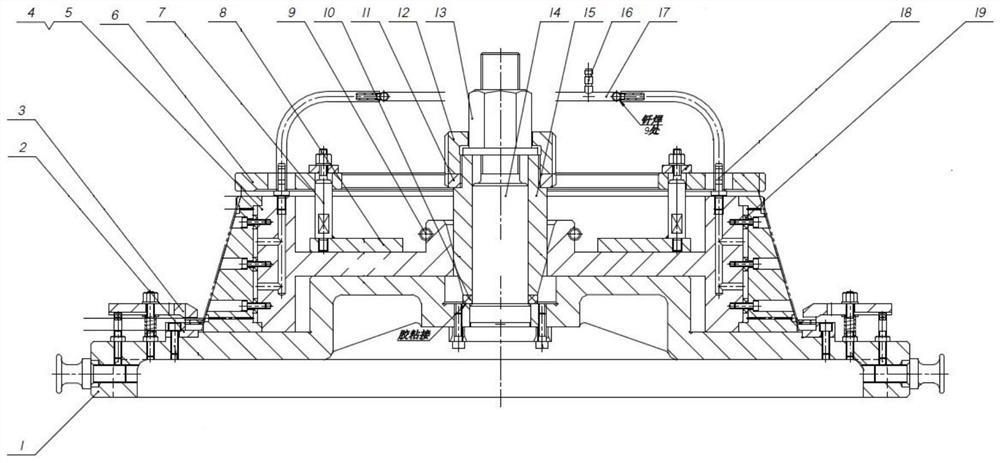

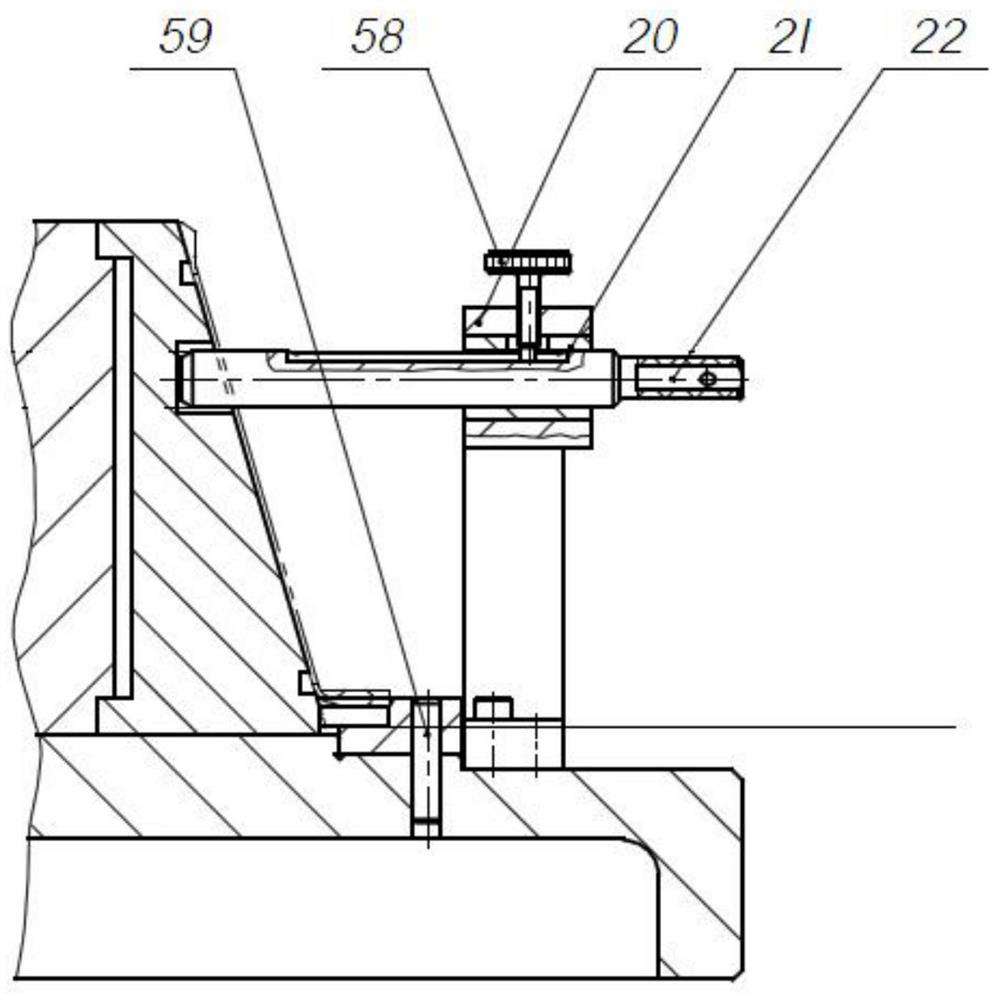

[0032] like Figure 1-6 As shown, a tooling for the overall assembly and welding of the engine outer ring assembly, including a chassis 1, a positioning ring 2, a pressure plate 3, a main expansion block 4, a secondary expansion block 5, a gland 6, a screw 7, a guide plate 8, and a spring 9 , rubber pad 10, lock nut 11, end cap nut 12, shoulder nut 13, guide column 14, cone 15, pipe joint nozzle 16, air guide pipe 17 and gas nozzle 18; The positioning ring 2 is pressed tightly on the outer edge of the chassis 1 and is interposed between the chassis 1 and the parts to be processed; the main expansion block 4 is a conical body whose outer side is compatible with the parts to be processed, and the expansion block 5 is an annular cylindrical shape with a hollow interior. , the main expansion block 4 is set on the outside of the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com