Punching tool and stamping and punching method

A technology of punching and tooling, which is applied in the field of stamping and punching, can solve the problems of low precision, inability to guarantee the position and shape of the hole, and failure to meet the requirements of punching, so as to avoid the effect of placing and picking up parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

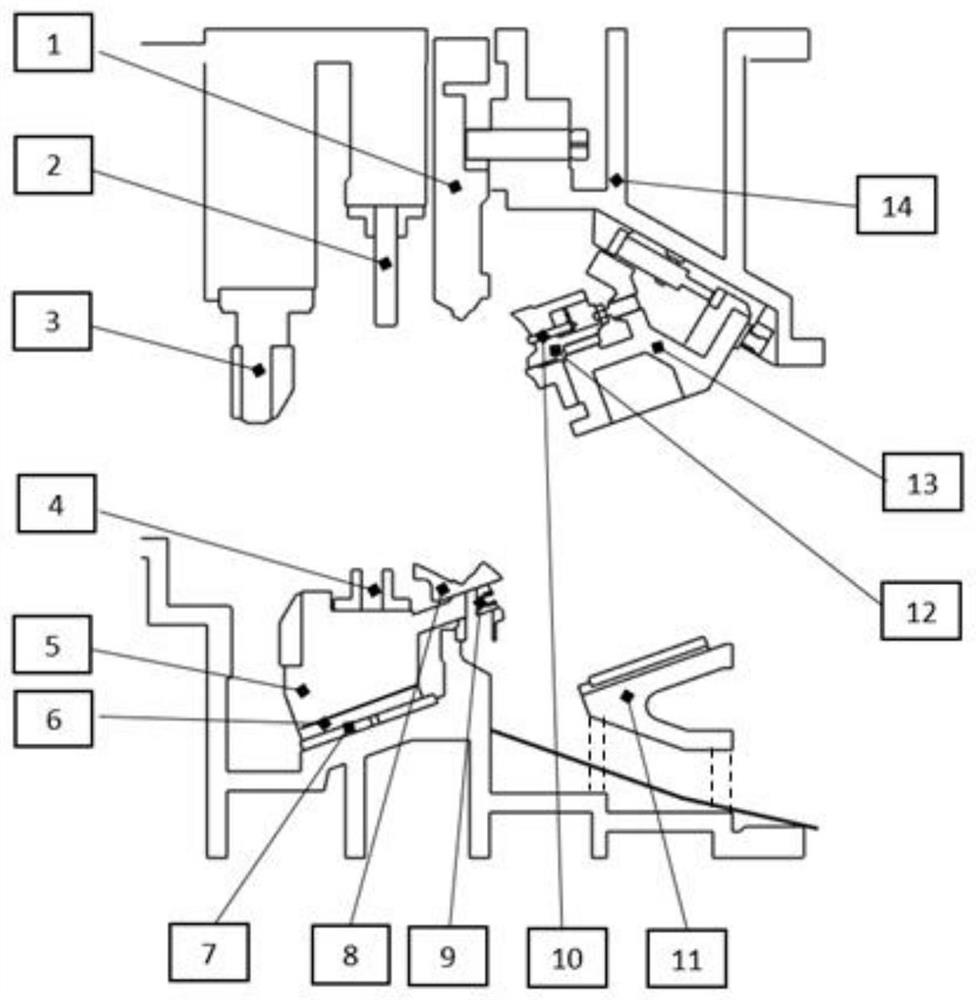

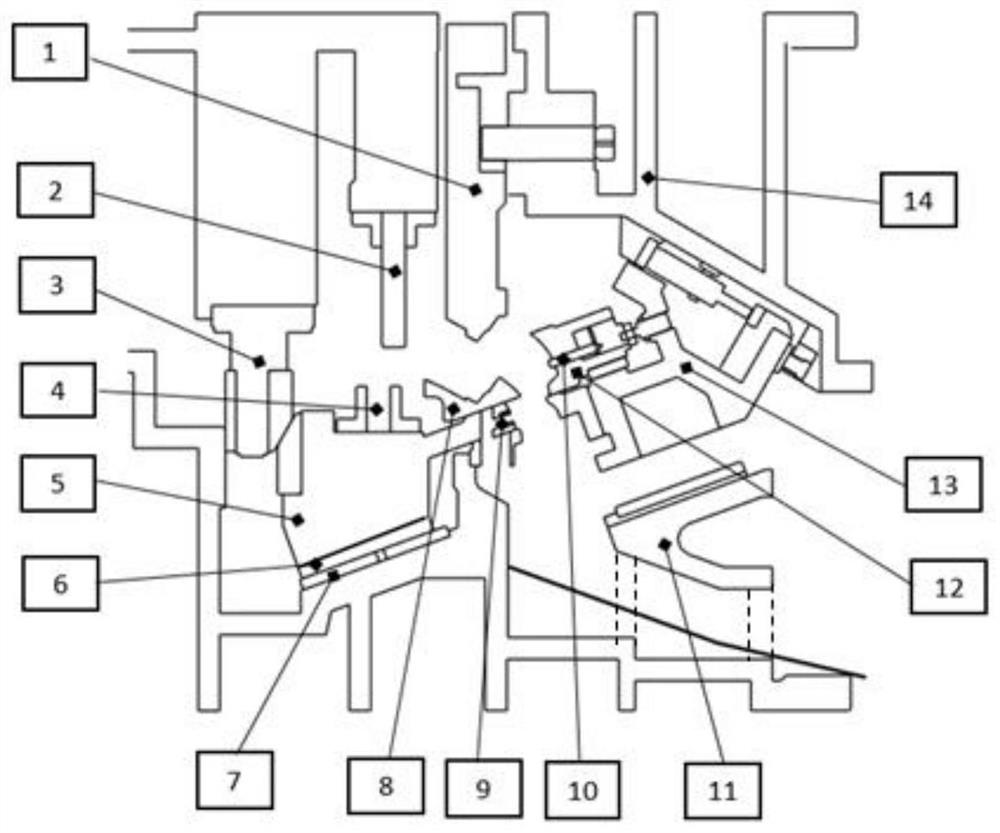

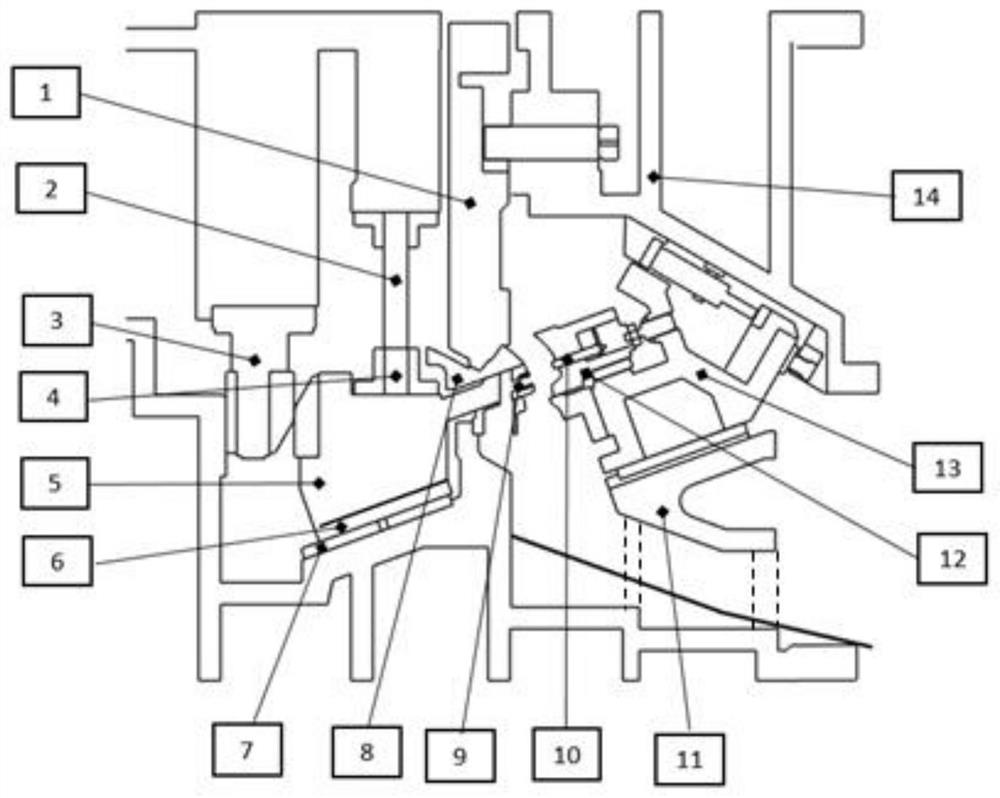

[0033] Such as Figure 1-Figure 4 As shown, the present embodiment provides a punching tool, including an upper base 14, a base 15, a first guide structure, a punch 5, a die sleeve 9 and a punch 10 arranged on the upper base 14, wherein: the base 15 is provided with a guiding inclined surface, and the punch 5 is slidingly matched with the guiding inclined surface. Due to the existence of the guiding inclined surface, when the punch 5 moves to the set direction, it is affected by its own gravity component to ensure the smooth and accurate movement of the punch 5. . The die set 9 is set on the punch 5, and the die set 9 is matched with the punch 10, the die set 9 is set on the base 15 along with the punch 5, and the movement of the punch 5 can avoid interfering with the removal of parts. It can realize the punching in the stamping process. The first guide structure includes a matching guide post 2 and a guide sleeve 4, one of which is set on the upper base 14, and the other is...

Embodiment 2

[0049] Based on the same inventive concept, a stamping and punching method provided by the present invention is implemented based on the above-mentioned punching tooling, including the following steps:

[0050] Place the parts to be punched on the base 15. Specifically, the parts to be punched are placed on the cover plate 8 fixedly arranged on the base 15. Since the punch 5 is movable, it is possible to operate the punch when picking and placing the parts. 5, to avoid interference with the loading and unloading of parts.

[0051] Control the upper base 14 to move the first set distance along the stamping direction, so that the punch 5 moves to the first set position along the guide slope, and the guide post 2 and the guide sleeve 4 are docked; the punch 5 is on the upper base 14 and the guide slope Compared with the horizontal guidance in the prior art, the present invention ensures the operation accuracy of the punch 5 through the inclined surface, avoiding the positioning d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com