A plunger sticking dipping line

A dipping line and dipping technology, which is applied in the direction of climate sustainability, coating, pretreatment surface, etc., can solve the problems of poor dipping effect, low dipping efficiency, and endangering the health of staff, and achieve processing efficiency Improvement, high degree of automation, good effect of dipping and drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be further described below in conjunction with specific embodiments. However, the purposes and purposes of these exemplary embodiments are only used to illustrate the present invention, and do not constitute any limitation to the actual protection scope of the present invention, nor do they limit the protection scope of the present invention.

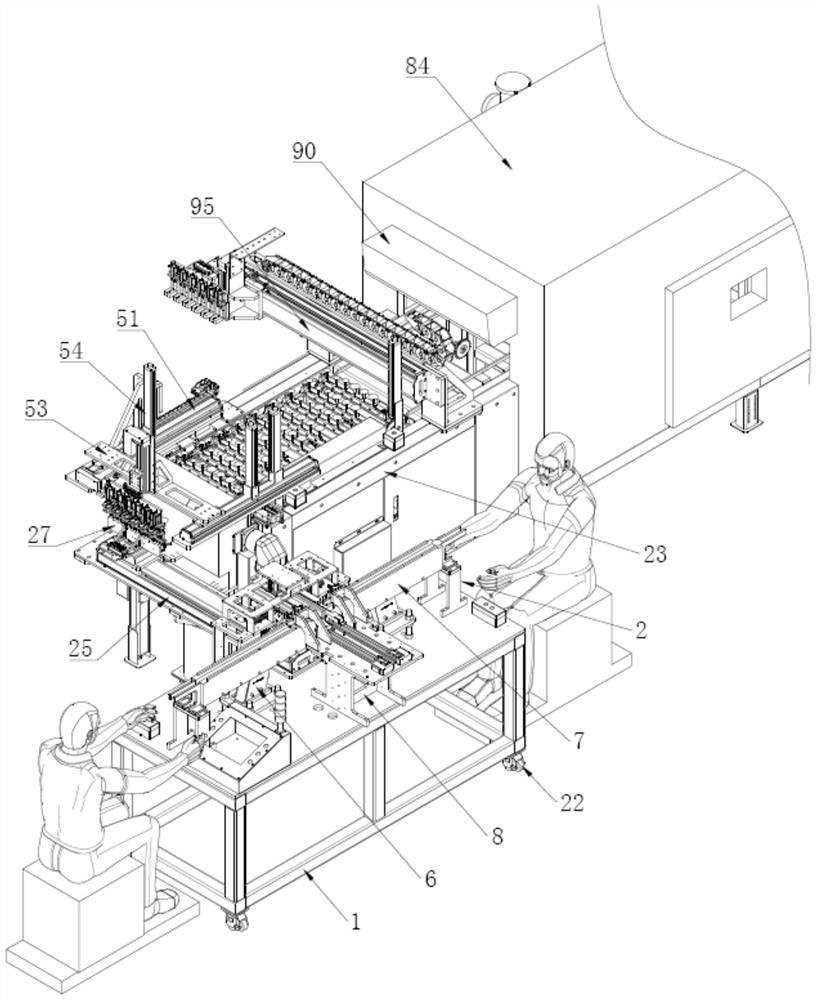

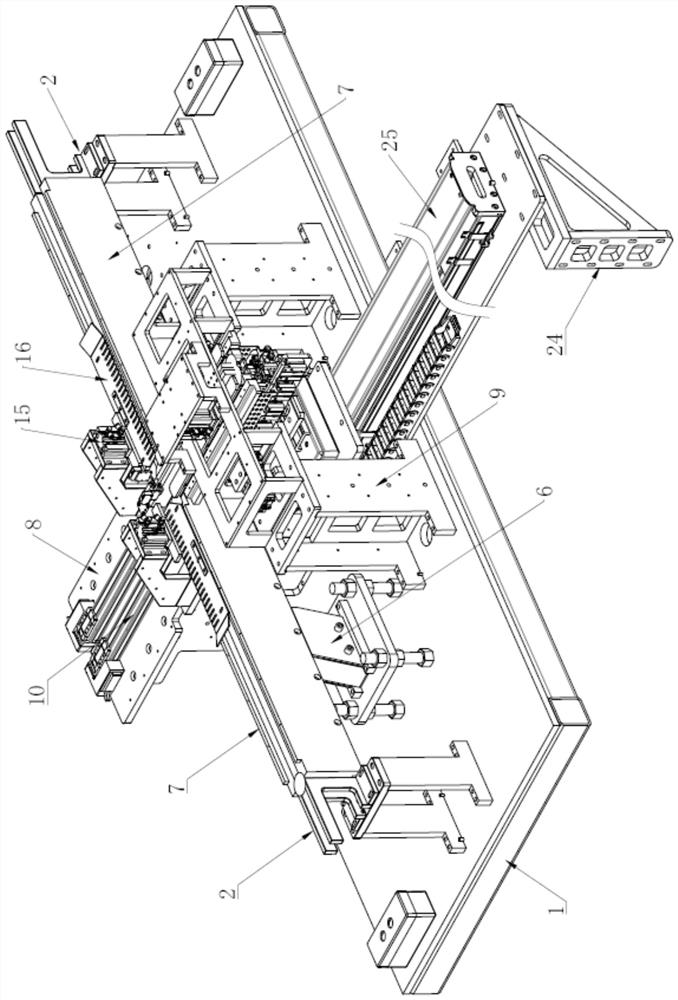

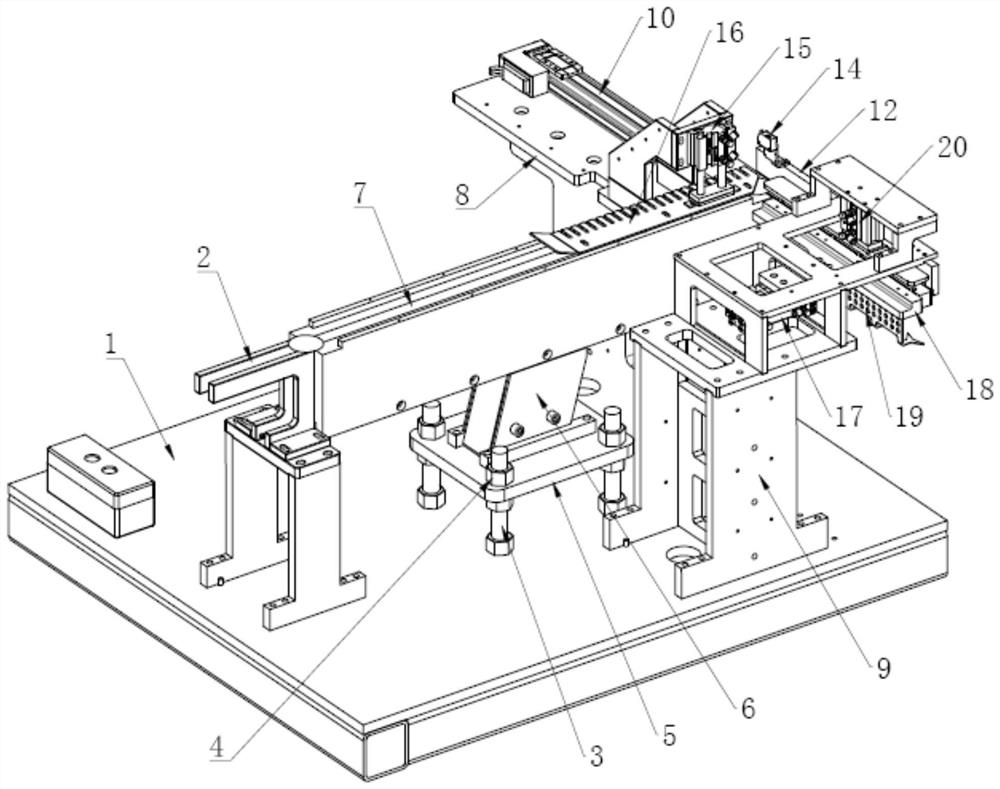

[0068] like figure 1 , figure 2 and Figure 9 As shown in common, this embodiment provides a plunger sticking and dipping line, including a dipping and drying frame 23, and a rotary chain 32 driven by a driving device is provided on the dipping and drying frame 23, and the rotary chain 32 is evenly There are several positioning jigs for realizing the positioning and clamping of the plunger to the workpiece. The feeding and unloading positions of the dipping drying rack 23 are provided with a jig opening and closing driving mechanism for realizing the opening and closing of the positioning jig. The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com