Quick-frozen flour-coated meat product rich in nutrition and preparation method thereof

A nutrient-rich, powdered meat technology, applied in food forming, food science, application, etc., to achieve the effects of avoiding agglomeration, improving work efficiency, and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

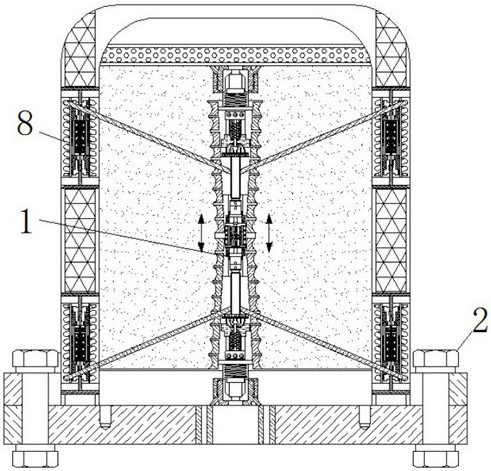

[0034] see Figure 1-4 , a kind of nutrient-rich quick-frozen powder-coated meat product preparation method, comprises the following steps:

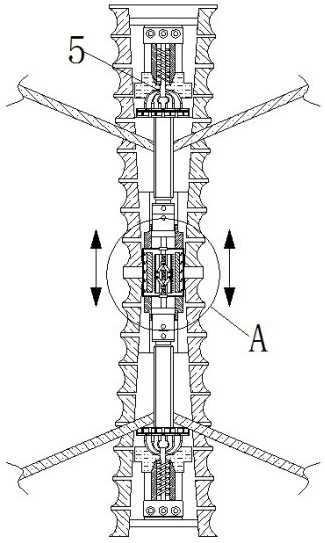

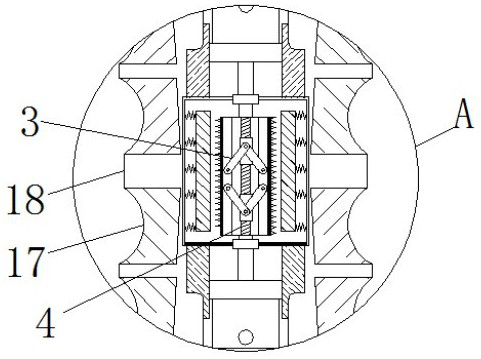

[0035] S1. Place the crushed minced meat inside the casing 2, add a certain amount of liquid flavoring agent, put the flavoring agent into the material storage plate 9 at the same time, and pass drinking water into the water supply tank 5 at the same time, then Drive the external drive motor to rotate the rotating shaft 3 intermittently, and add flour;

[0036] S2, the rotation of the rotating shaft 3 drives the telescopic frame 4 to shrink, and the telescopic frame 4 shrinks and pulls the replenishment tank 5 to approach each other, and the replenishment tank 5 moves. The return spring 15 exerts a certain force on the surface of the water storage bag 14 under the action of inertia, and the water storage bag 14 Under pressure, the moisture inside will be discharged from the drainage board 16 and sprayed on the surface of the wound metal...

Embodiment 2

[0041] see Figure 1-5 , a kind of nutrient-rich quick-frozen powder-coated meat product preparation method, comprises the following steps:

[0042] S4. The metal wire 11 adhered with seasoning will be in contact with the minced meat when stretching out and shrinking. Simultaneously, because there is a height difference between the material storage plate 9 and the replenishing water tank 5, when the metal wire 11 is in contact with it, it will constantly be different from the meat. contact with minced meat, that is, to avoid the accumulation of minced meat and the situation that it cannot contact with flavoring agent;

[0043] S5. When the metal wire 11 adhered with flavoring agent and moisture is constantly in contact with the minced meat, the minced meat is being kneaded continuously and in contact with the flour, and while the rotating shaft 3 is rotating, the telescopic frame 4 shrinks and pulls the slide plate 19 in The movement of the inside of the housing 2 and the mov...

Embodiment 3

[0047] see Figure 1-6 , a kind of nutrient-rich quick-frozen powder-coated meat product preparation method, comprises the following steps:

[0048] S1. Place the crushed minced meat inside the casing 2, add a certain amount of liquid flavoring agent, put the flavoring agent into the material storage plate 9 at the same time, and pass drinking water into the water supply tank 5 at the same time, then Drive the external drive motor to rotate the rotating shaft 3 intermittently, and add flour;

[0049] S2, the rotation of the rotating shaft 3 drives the telescopic frame 4 to shrink, and the telescopic frame 4 shrinks and pulls the replenishment tank 5 to approach each other, and the replenishment tank 5 moves. The return spring 15 exerts a certain force on the surface of the water storage bag 14 under the action of inertia, and the water storage bag 14 Under pressure, the moisture inside will be discharged from the drainage board 16 and sprayed on the surface of the wound metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com