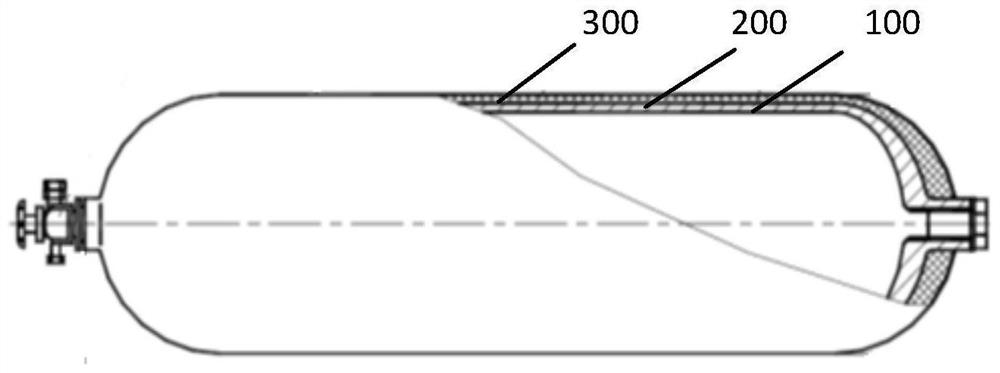

Aluminum alloy inner container ultrahigh-pressure full-wrapped gas cylinder and manufacturing method thereof

A technology of winding gas cylinders and aluminum alloys, which is applied in the direction of manufacturing tools, container structure manufacturing, pressure vessels, etc., to achieve the effects of simple preparation process, low pollution, and excellent overall strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0155] In the embodiment of the present application, an aluminum alloy liner 100 for an ultra-high pressure gas cylinder with a diameter of 420 mm, a length of 2.5 m, and a wall thickness of 4 mm is manufactured through the above-mentioned manufacturing method of an ultra-high pressure fully wound gas cylinder with an aluminum alloy liner, wherein , the rated pressure of the ultra-high pressure gas cylinder is required to be 35Mpa, and the specific steps are as follows:

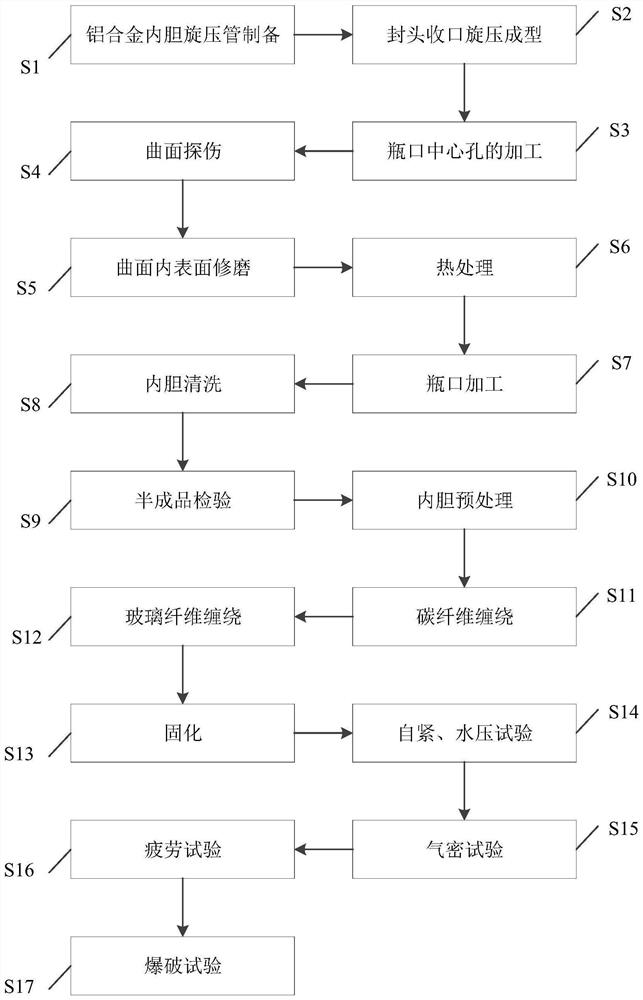

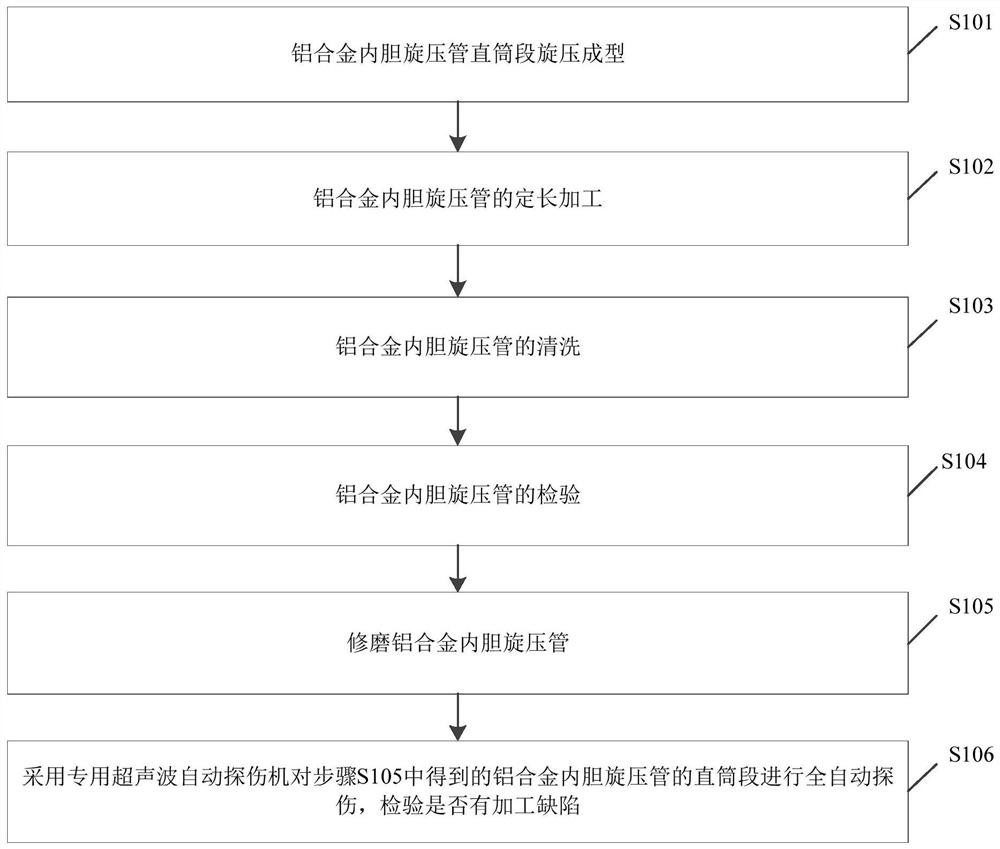

[0156] Step S1, preparation of aluminum alloy liner spinning tube, including:

[0157] Step S101, the spinning forming of the straight section of the aluminum alloy liner spinning tube, using the three-wheel staggered forward spinning method to perform 2-pass spinning on the seamless pipe with a length of 1m, and the three-wheel staggered forward spinning method The misalignment in the method is set to 6mm;

[0158] Obtain the first spinning part (spinning part A), the first spinning part (spinning part A) i...

Embodiment 2

[0236] In the embodiment of the present application, an aluminum alloy liner 100 for an ultra-high pressure gas cylinder with a diameter of 618 mm, a length of 4.5 m, and a wall thickness of 6 mm is manufactured through the above-mentioned manufacturing method of an ultra-high pressure fully wound gas cylinder with an aluminum alloy liner. The rated pressure requirement of ultra-high pressure gas cylinder is 45Mpa, the specific steps are as follows:

[0237] Step S1, preparation of aluminum alloy liner spinning tube;

[0238] Specifically, step S1 includes:

[0239] Step S101, Spinning forming of the straight section of the aluminum alloy liner spinning tube: using the three-wheel staggered reverse-spinning method to perform three-pass spinning on the seamless pipe with a length of 1.5m, and three-wheel staggered reverse-spinning The misalignment in the pressing method is set to 6mm;

[0240] Obtain the first spinning part (spinning part A), the first spinning part (spinning...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com