Transmission control structure

A control structure and transmission technology, applied in the direction of shafts and bearings, components with teeth, transmission device control, etc., can solve the problems that affect the driving experience, serious vibration of the handle ball in the cab, etc., and achieve weight reduction and difficulty deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

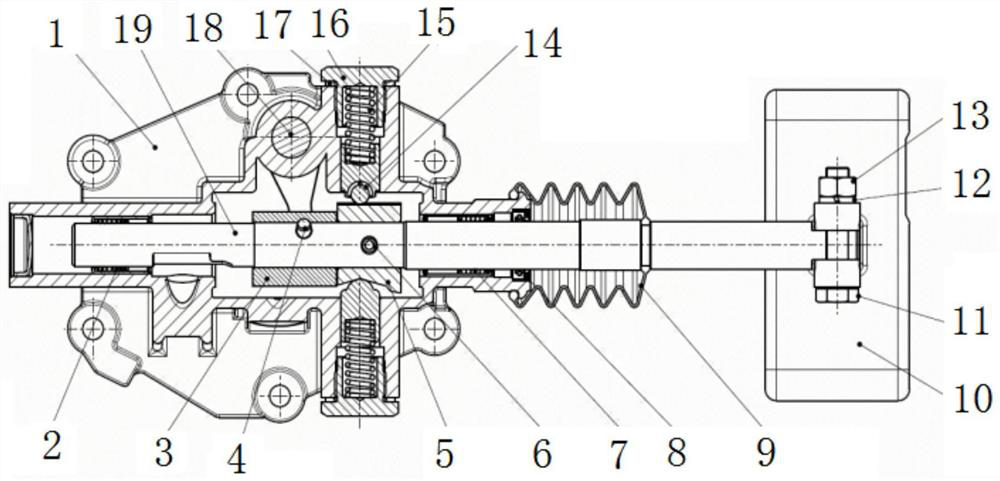

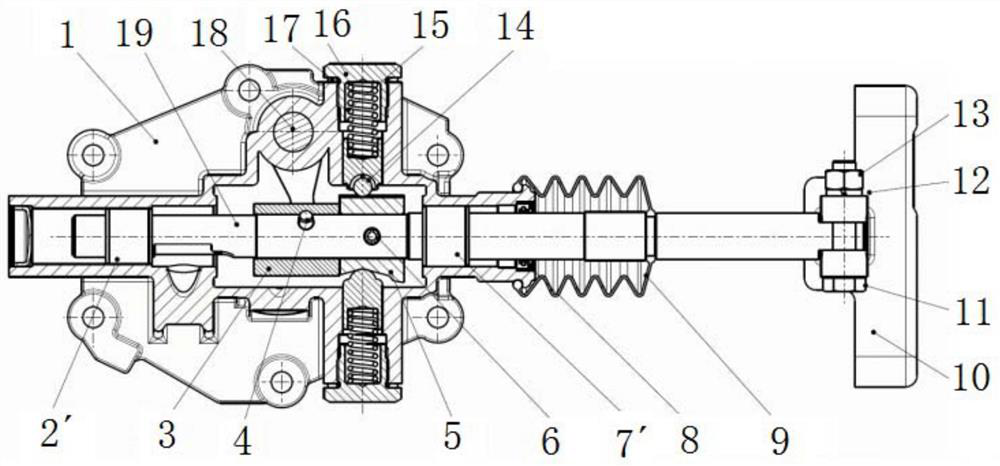

[0015] After analysis and research and NVH tests, the applicant learned that the vibration of the handle ball in the cab originated from the transmission control structure of the C6J45T transmission ( figure 1 ) in the counterweight 10, the cylindrical pin 4 on the counterweight 10 is connected with the gear shifting flexible shaft, and the flexible shaft is connected with the cab handball, which can be understood as the vibration of the transmission control system is transmitted to the cab handle ball through the flexible shaft, After analysis, the jitter problem has the following two potential causes:

[0016] 1. In the control structure of the C6J45T transmission, two linear bearings ( figure 1 Marks 2 and 7 in ), during the press-fitting process of the linear bearing, the outer ring is easily deformed and then the steel ball of the inner ring is compressed to be in close contact with the outer circle of the horizontal shift lever 19 . From the perspective of vibration tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com