Ink-jet printing method for nylon wool carpet

A technology of inkjet printing and wool, which is applied in dyeing, textiles and papermaking, etc. It can solve the problems of paste melting, difficult degradation, difficulty, etc., and achieve the effect of easy paste melting, good compatibility and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

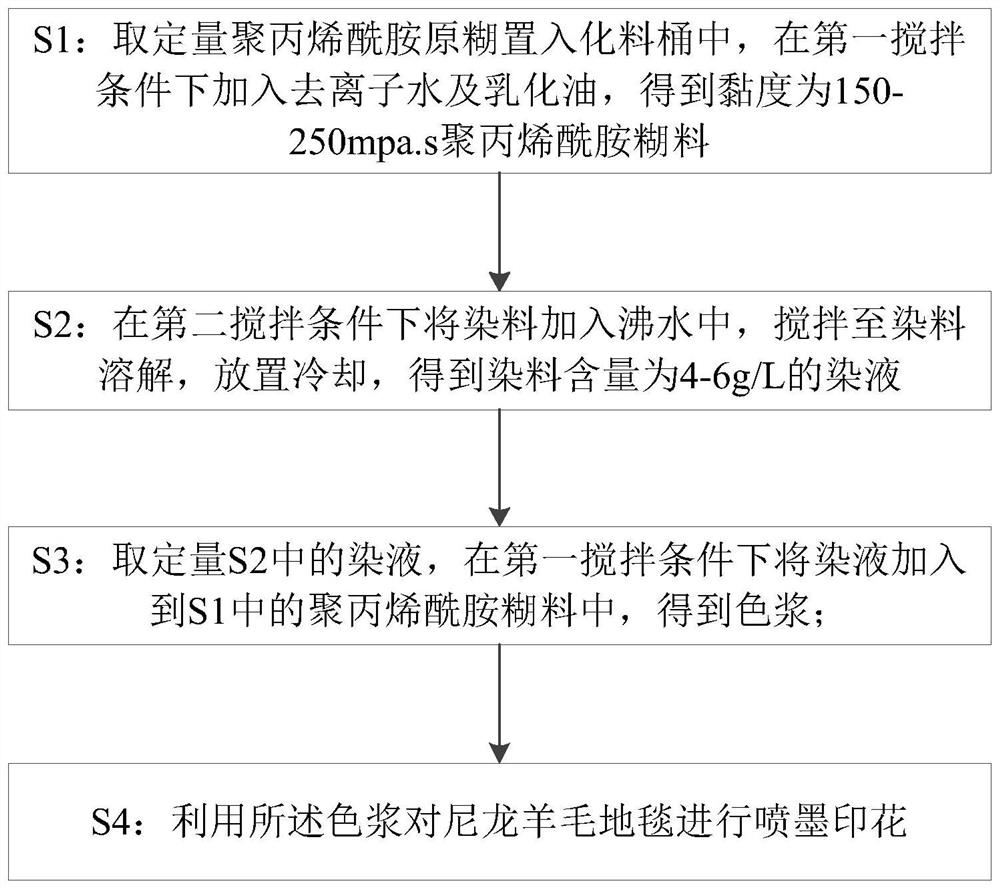

Method used

Image

Examples

preparation example Construction

[0045] In the present embodiment, the preparation method of polyacrylamide stock paste comprises:

[0046] S1: Weigh 4-9% of acrylamide by weight, 0.25-0.50% of ammonium persulfate relative to acrylamide, 0.25-0.50% of residual ammonium persulfate treatment agent relative to acrylamide, 2-5 % of polyacrylamide viscosity remover, deionized water, the sum of the above components is 100%.

[0047] S2: Dissolving the weighed acrylamide and ammonium persulfate in deionized water to make a reaction solution;

[0048] S3: adding the reaction solution prepared by S2 into the reaction kettle under stirring;

[0049] S4: Raise the temperature of the reactor to 60-80°C for 1-2 hours;

[0050] S5: Add the residual ammonium persulfate treatment agent weighed in S1 into the reaction kettle for reaction, and stir for 10-30min;

[0051] S6: Add the polyacrylamide viscosity remover weighed in S1 into the reaction kettle for reaction, and stir for 10-30 minutes, then cool the reaction kettle...

Embodiment 1

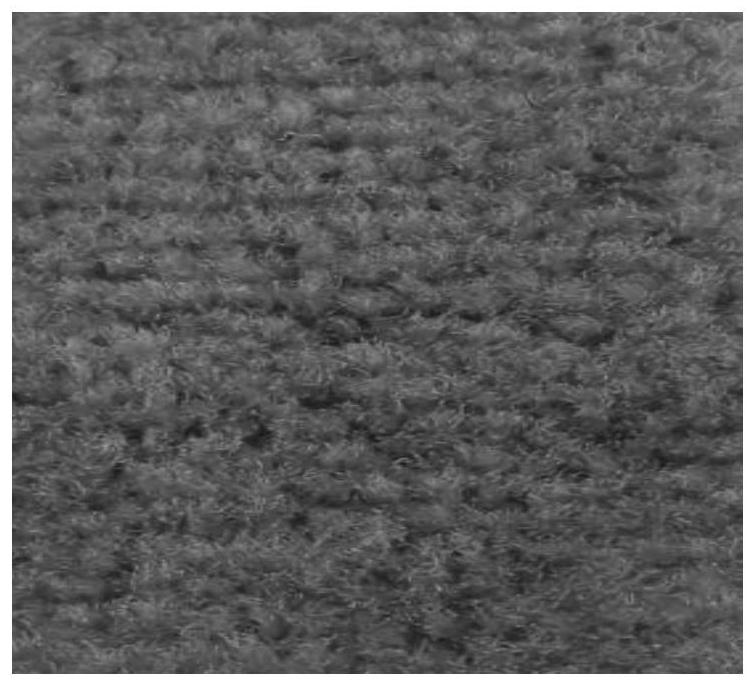

[0055] In Example 1 of the present invention, take 33L of polyacrylamide raw paste with an average molecular weight of 880,000 and an average viscosity of 89,000mpa·s, put it into the chemical tank, turn on the agitator, the speed of the agitator is 400rpm, and add 64L of deionized Water and 3L emulsified oil were stirred for 15 minutes to obtain a polyacrylamide paste; 10g of brown acid dye was completely dissolved in 2L of boiling water to obtain a dye solution, cooled to room temperature, filtered through a sieve and evenly added to the polyacrylamide paste. Stir for 15 minutes to obtain the color paste. The average viscosity of the color paste is 195mpa s, the average water holding capacity is 0.48cm / 15min, and the average printing viscosity index PVI is 0.855. The speed of the printing equipment is set to 65cm / min, and the pressure is set to 1.5MPa. Inkjet printing on 1000 grams of nylon wool blank blanket, the printing effect is as follows figure 2 shown.

Embodiment 2

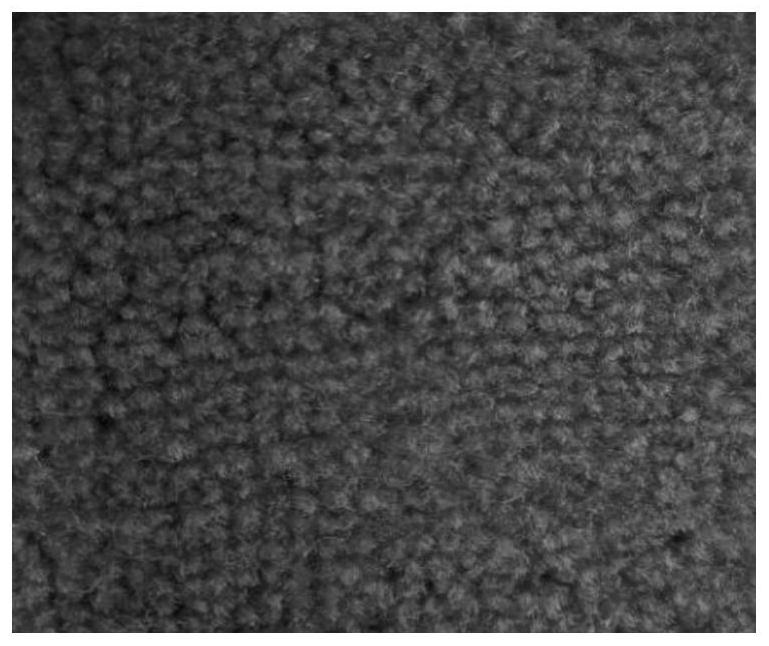

[0057] In Example 2 of the present invention, take 32L of polyacrylamide raw paste with an average molecular weight of 860,000 and an average viscosity of 84500mpa·s, put it into the chemical tank, turn on the agitator, the speed of the agitator is 400rpm, add 65L of deionized Mix water and 3L emulsified oil for 15 minutes to obtain polyacrylamide paste; completely dissolve 10g of dark blue acid dye in 2L of boiling water to obtain a dye solution, cool down to room temperature, filter through a sieve and evenly add to polyacrylamide paste , stirred for 15 minutes to obtain the color paste, the average viscosity of the color paste is 185mpa s, the average water holding capacity is 0.51cm / 15min, the average printing viscosity index PVI is 0.840, the speed of the printing equipment is set to 65cm / min, and the pressure is set to 1.6MPa , inkjet printing on 1200 grams of nylon wool blank blanket, the printing effect is as follows image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com