Rubber hose and preparation method thereof

A rubber glue and rubber technology, applied in rubber layer products, chemical instruments and methods, tubular articles, etc., can solve the problems of large environmental pollution, dangerous raw materials, consumption of water and electricity and other resources, and achieve simple process settings and good compatibility. Sexual, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

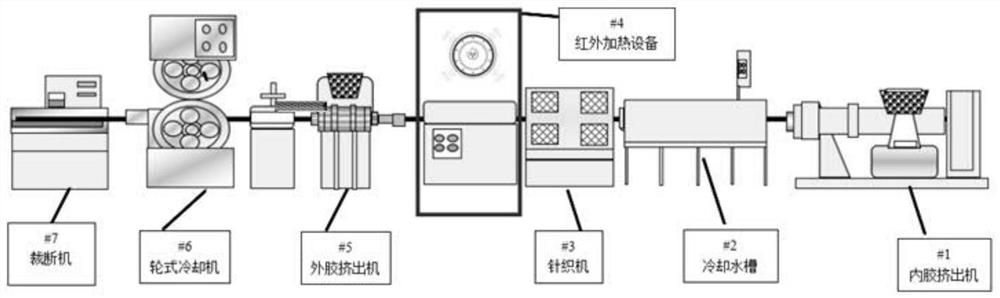

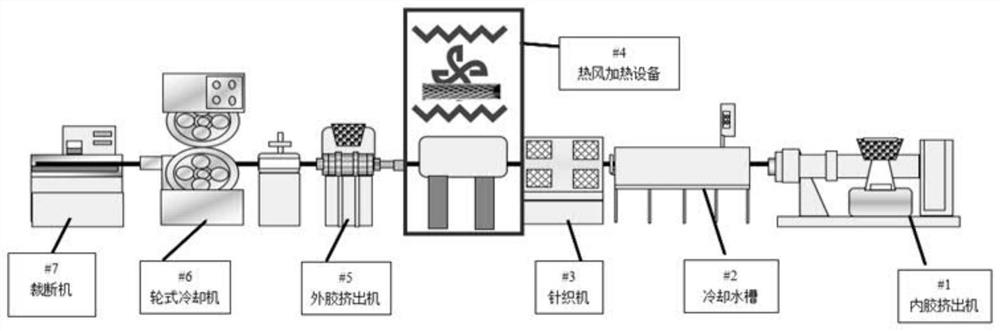

[0044] According to one aspect of the present invention, a kind of preparation method of above-mentioned rubber hose, described preparation method comprises the following steps:

[0045] Extrude the inner rubber layer on the mold core, weave the fiber-reinforced layer on the inner rubber layer after cooling, then perform heat treatment, and then extrude a layer of outer rubber layer on the fiber-reinforced layer to obtain a rubber hose.

[0046] In the preparation method of the rubber hose provided by the present invention, the preparation method first extrudes the inner rubber layer on the mold core, weaves the fiber reinforced layer on the inner rubber layer after cooling, then performs heat treatment, and then extrudes the inner rubber layer on the fiber reinforced layer. A layer of outer rubber layer is produced to obtain a rubber hose. Compared with the existing method of spraying chemical additives to change the shape of the inner tube to achieve the bonding effect, the ...

Embodiment 1

[0063] A kind of preparation method of rubber hose, described preparation method comprises the following steps:

[0064] (1) Extrude the inner rubber layer on the mold core, and obtain the inner rubber layer after cooling; then wind the inner tube onto a large mandrel, and then weave the individual inner tube, and then roll it on to obtain the coating Inner hose with fiber reinforcement;

[0065] The rubber type of the inner rubber layer is EPDM, the plasticizer is petroleum wax with a molecular weight of 6% to 8%, and the content of the plasticizer is 15 parts;

[0066] The fibers of the braided fiber reinforced layer are aramid yarns with a size of 1100date;

[0067] The specific extrusion process of the braided product is as follows: firstly, the core extrusion of the inner tube is completed at a speed of about 10m / min, and the upper roll is cooled for use, and then the inner tube is braided and covered with a reinforcing layer at a speed of 6m / min, and the upper roll Sta...

Embodiment 2

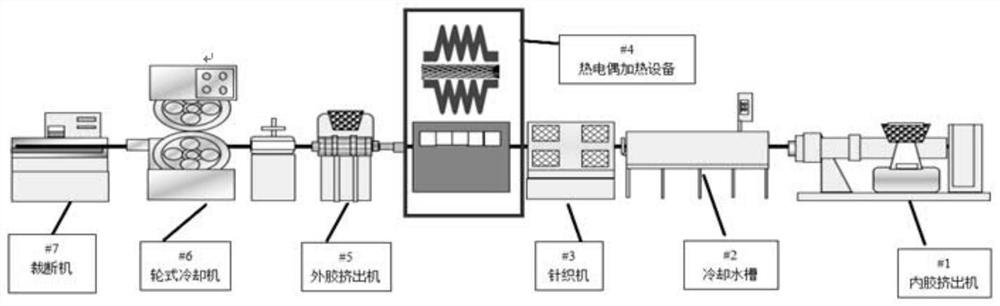

[0072] A kind of preparation method of rubber hose, described preparation method comprises the following steps:

[0073] (1), with embodiment 1;

[0074] (2), heat-treating the inner rubber tube coated with the fiber reinforced layer, then extruding a layer of outer rubber layer on the fiber reinforced layer to obtain the rubber rubber tube;

[0075] The glue kind of described outer glue layer is with embodiment 1;

[0076] Such as figure 2 As shown, the heat source of the heat treatment in this embodiment is a thermocouple heating heat source. In the thermocouple heating method, due to the excellent thermal conductivity of ceramics, setting it at 500°C can ensure that the surface temperature of the product reaches 90-100°C. qualified.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com