Machining tool and machining method for embedded sealing ring

A sealing ring and mosaic technology, which is applied in the direction of stone processing tools, metal processing, stone processing equipment, etc., can solve the problem of insufficient dimensional accuracy and shape and position tolerance accuracy, poor reliability of end face seal in product qualification rate, and reduced reliability of end face seal, etc. problem, to achieve the effect of improving dimensional accuracy and geometric tolerance accuracy, reducing local trimming of graphite and reducing oxidation and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with the accompanying drawings and exemplary embodiments.

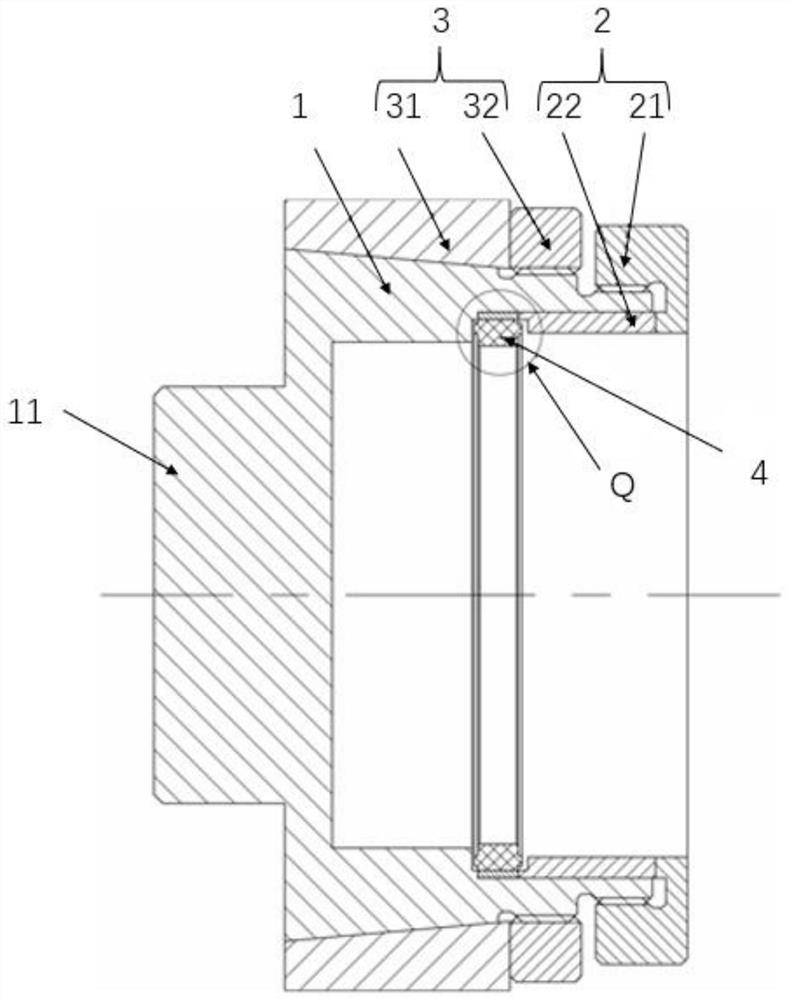

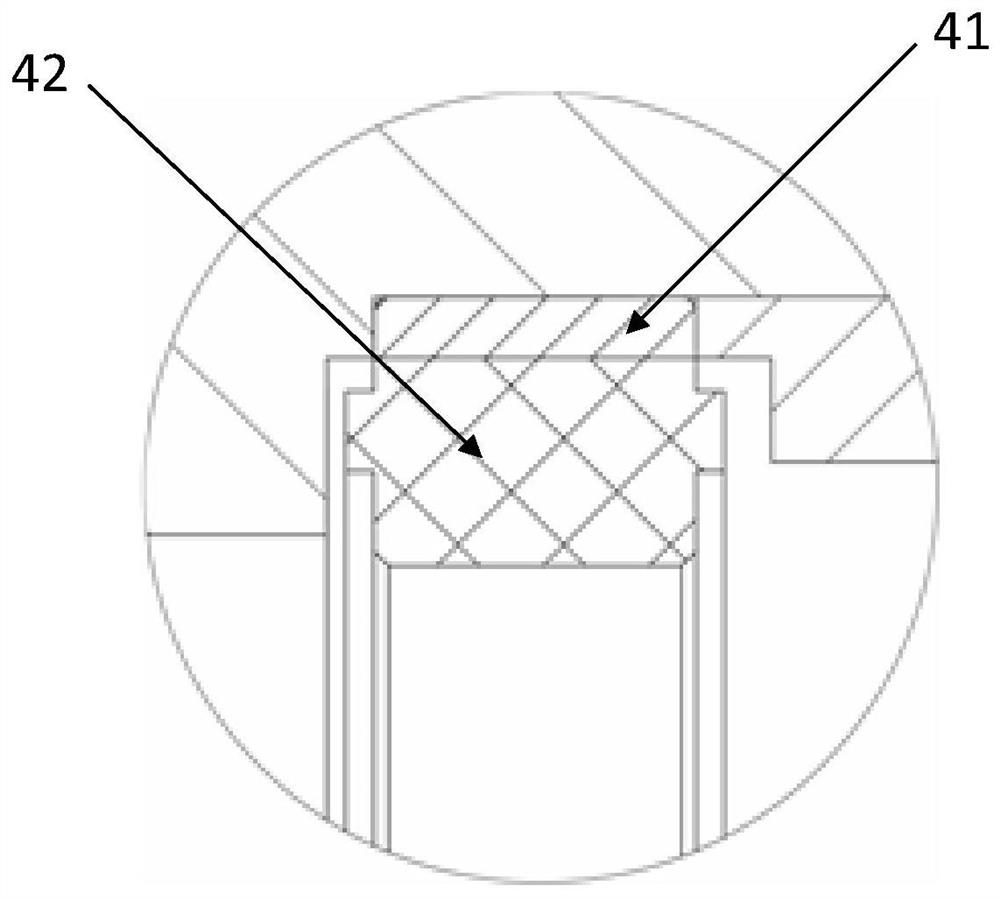

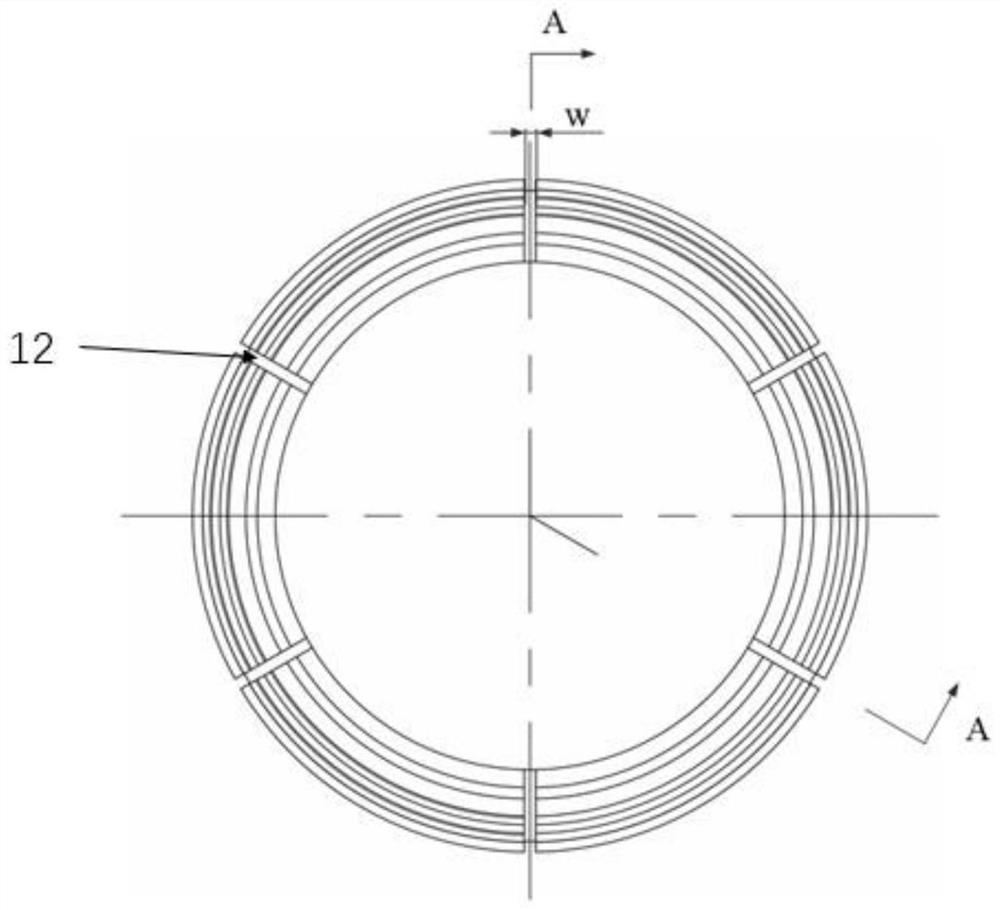

[0057] refer to figure 1 , a processing tool for an inlaid sealing ring, including a fixture seat 1, an axial positioning device 2 and a radial positioning device 3; one end of the fixture seat 1 is provided with a clamping part 11 connected with a machine tool, and the other end is provided with an axial blind The axial blind hole includes a first axial hole, a second axial hole and a third axial hole which are arranged sequentially from the inside to the outside and have an increasing diameter. The first axial hole and the second axial hole form the first axial hole. The step end face, the second step end face is formed between the second axial hole and the third axial hole, the inlaid seal ring 4 to be processed realizes axial positioning through the close contact between the end face of the metal ring seat 41 and the second step end face, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com