Externally-square and internally-circular coil pipe and machining device thereof

A technology of processing device and inner disk, which is applied to pipe shearing devices, shearing devices, metal processing equipment, etc., can solve the problems of pipe cutting deviation and the pipe port is not flat enough, so as to avoid uneven cutting and improve practicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

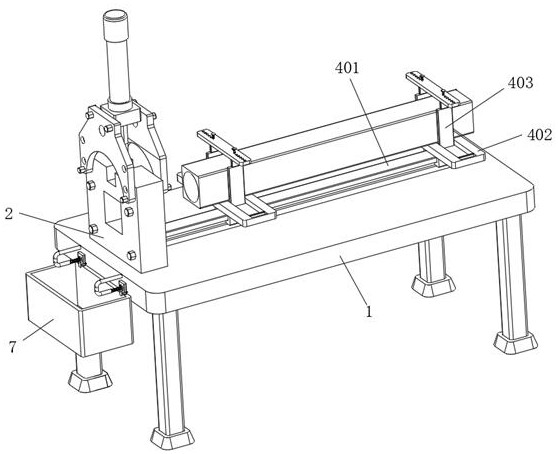

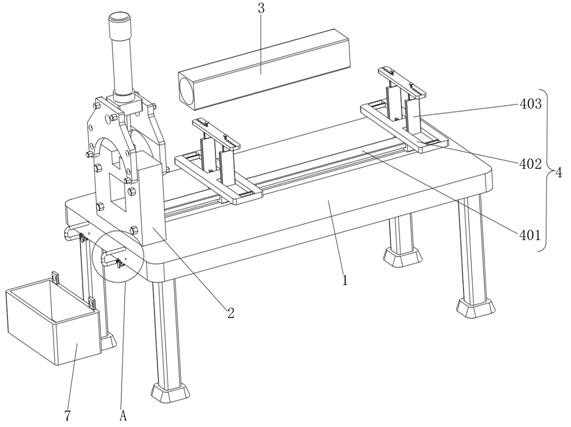

[0029] Example 1, such as Figure 1-5As shown, the present invention provides an outer square inner circular coil and its processing device, which is mainly composed of a processing table 1, a cutting machine 2, a coil body 3 and a fixing device 4, and the upper end of the processing table 1 is provided with a cutting machine 2. A coil body 3 is placed on the end of the processing table 1 close to the cutting machine 2. The shape of the coil body 3 is square, and the inner cavity of the coil body 3 is cylindrical.

[0030] Let's talk about the specific settings and functions of its fixing device 4, collecting device 5 and buffer device 6 in detail below.

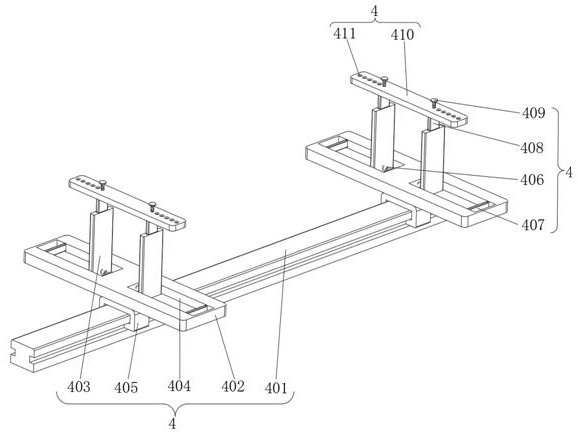

[0031] like figure 1 and figure 2 As shown, the end of the processing table 1 relative to the cutting machine 2 is provided with a fixing device 4. The fixing device 4 includes a slide rail 401. The bottom end of the slide rail 401 is welded to the processing table 1. The slide rail 401 is in the shape of "I", and the sli...

Embodiment 2

[0035] Example 2, such as Figure 7 and Figure 8 As shown, on the basis of Embodiment 1, the inside of the storage box 7 is provided with a buffer device 6, the buffer device 6 includes a bottom column 61, one end of the bottom column 61 is welded to the storage box 7, and the inside of the bottom column 61 is slidably connected with a sliding Column 62, the end of the sliding column 62 away from the bottom column 61 is welded with a base 63, the base 63 is "U" shaped, the end of the base 63 away from the sliding column 62 is engaged with a chassis 65, and the end of the base 63 away from the chassis 65 is fixed with two One elastic piece 64, and two elastic pieces 64 are symmetrically distributed with the central axis of base 63, and elastic piece 64 is " V " font, and one end of elastic piece 64 away from base 63 is fixedly connected with storage box 7, and the side wall of storage box 7 is provided with rectangular groove 68, both sides of the chassis 65 are slidingly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com