Melt impacting, crushing and granulating system and method

A granulation and melt technology, which is applied in grain processing and other directions, can solve the problems of high energy consumption, dust pollution of the working environment, and reduced control of granulation effect, and achieves simple operation process, good granulation effect, and energy consumption. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

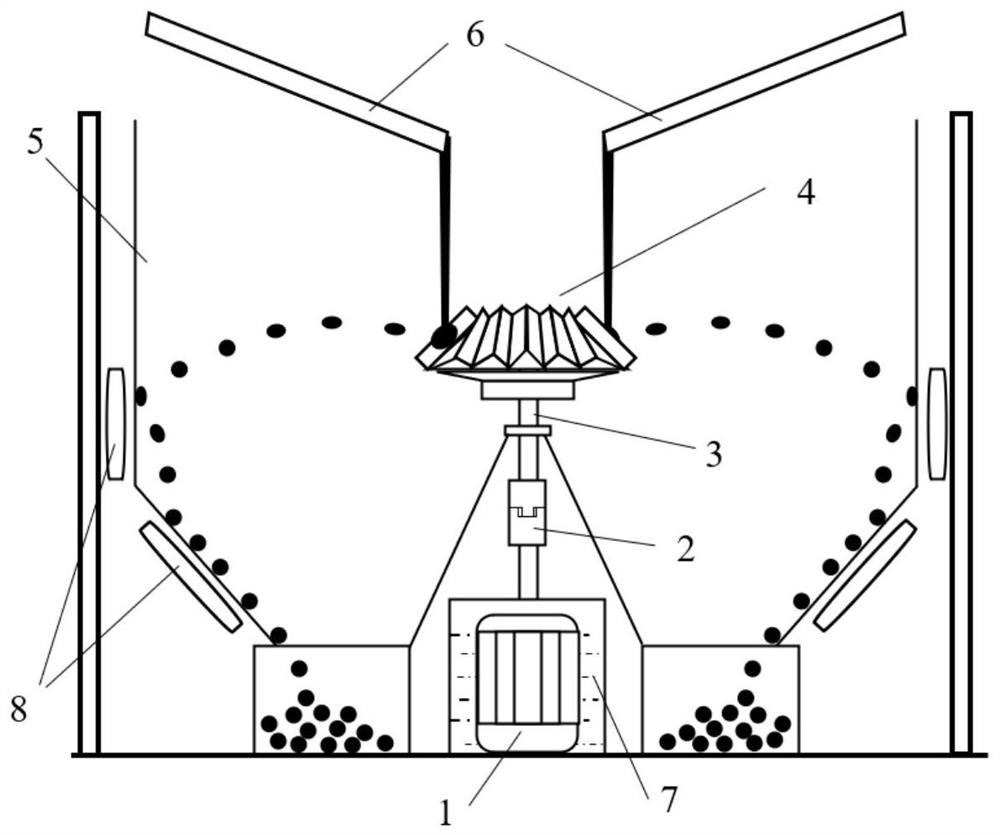

[0050] In this embodiment, the impact member is a bevel gear, and the tooth surface of the bevel gear faces the direction of the melt falling; the number of teeth of the bevel gear is 30, the tooth width is 100 mm, and the indexing cone angle is 45°, and the impact area of the bevel gear is 45°. The average tooth height of the bevel gear is 50mm, and the speed of the bevel gear is 500 r / min (greater than the lower limit of the speed) );

[0051] In this embodiment, the power transmission assembly includes a drive motor 1 and a coupling 2, the drive motor 1 provides a driving force, and the rotating shaft 3 of the impact crushing and granulation assembly is driven to rotate under the connection transmission of the coupling 2, and then Drive the bevel gear 4 as the striker on the shaft.

[0052] The working principle of the system described in this embodiment is:

[0053] Turn on the drive motor 1, and through the connection of the coupling 2, the stably rotating motor shaf...

Embodiment 2

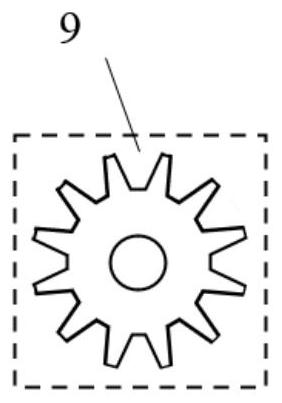

[0055] The impact member described in this embodiment is a cylindrical gear, which is arranged in such a way that the end face of the cylindrical gear faces upwards (the end face of the cylindrical gear faces the falling direction of the melt), and the melt falls between the teeth gaps, and then the tooth surface hits the melt from the side; The number of teeth of the cylindrical gear is 30, the tooth height is 100mm, the tooth pitch is 100mm, and the tooth width is 100mm. ).

[0056] The power transmission assembly described in this embodiment is a gear transmission assembly, which is used to adjust the position and direction of the drive motor and the upper and lower limits of the transmission speed. The gear transmission assembly includes a drive motor that provides rotational power, and is installed on the motor shaft The transmission gear, the transmission gear is connected to the rotating shaft; the transmission gear is a bevel gear, such as Figure 4 As shown, the use...

Embodiment 3

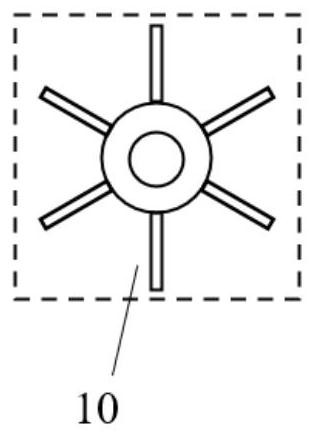

[0059] In this embodiment, the impactor is a drum with fins, and the installation method is that the end face of the drum faces upwards (the end face of the drum faces the direction where the melt falls). Impact the melt, there are 6 fins on the drum, the thickness of the fins along the circumference of the drum is 30mm, the length of the fins along the radial direction of the drum is 100mm, and the length of the fins along the axial direction of the drum is 100mm , the rotational speed of the rotor with fins during work is 1000 rpm (greater than the lower limit of rotational speed ).

[0060] The power transmission assembly described in this embodiment is a gear transmission assembly, which is used to adjust the position and direction of the drive motor and the upper and lower limits of the transmission speed. The gear transmission assembly includes a drive motor that provides rotational power, and is installed on the motor shaft The transmission gear, the transmission ge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tooth width | aaaaa | aaaaa |

| Tooth height | aaaaa | aaaaa |

| Tooth pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com