Banxia Qu and its preparation method

The technology of Banxia Qu and Qing Banxia is applied in the field of preparation of Banxia Qu, which can solve the problems of lowering production efficiency and achieve the effects of improving production efficiency and speeding up fermentation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

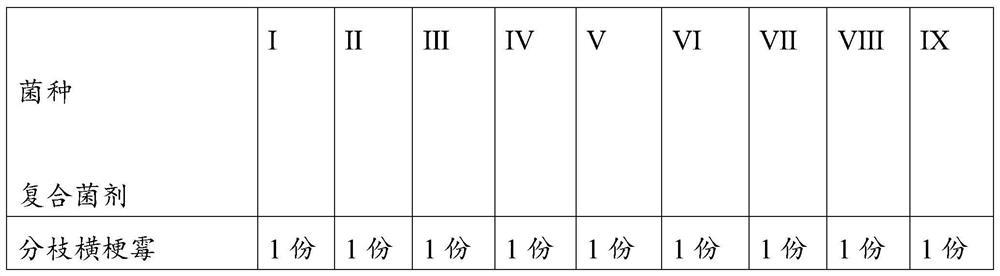

Method used

Image

Examples

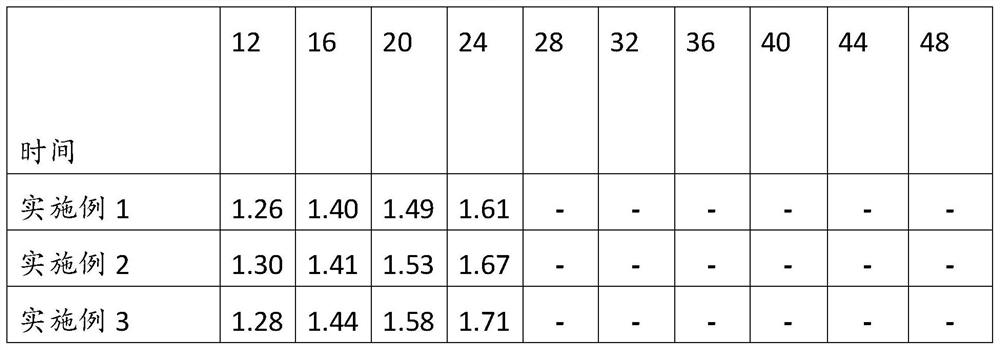

Embodiment 1

[0022] Crush 160 parts of Qing Pinellia, 10 parts of alum, and 5 parts of Liushenqu into 80-mesh flour; mix with 4 parts of ginger juice and 32 parts of flour to obtain a fermentation substrate. An appropriate amount of water was added to adjust the water content of the fermentation substrate to 55%.

[0023] The fermentation substrate is sterilized at low temperature by pasteurization.

[0024] Mix the compound bacterial agent I with the fermentation substrate at a mass ratio of 1:20, and cut into small pieces or make coarse grains under aseptic conditions. The diced or granulated fermentation substrate is placed in a fermentation box for fermentation, and the temperature in the fermentation box is kept at 28° C. and the relative humidity is kept at 75%.

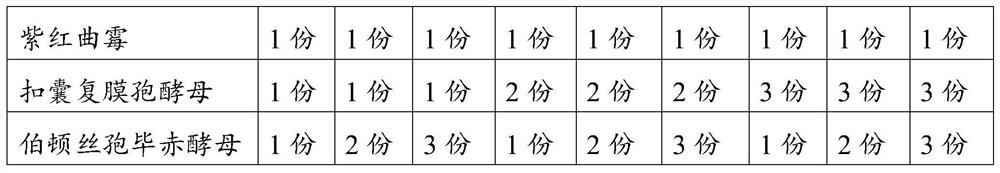

[0025] Start sampling after 12 hours of fermentation, and then take samples every 4 hours to test the liquefaction power and saccharification power of the sample. When the liquefaction power of the sample is greater than o...

Embodiment 2

[0028] Crush 180 parts of Qing Pinellia, 12 parts of alum, and 7 parts of Liushenqu into 80-mesh flour; mix with 6 parts of ginger juice and 36 parts of flour to obtain a fermentation substrate. Add an appropriate amount of water to adjust the water content of the fermentation substrate to 60%.

[0029] The fermentation substrate is sterilized at low temperature by pasteurization.

[0030] Mix the compound bacterial agent II with the fermentation substrate at a mass ratio of 1:40, and cut into small pieces or make coarse particles under aseptic conditions. The diced or granulated fermentation substrate is placed in a fermentation box for fermentation, and the temperature in the fermentation box is kept at 32° C. and the relative humidity is kept at 80%.

[0031] Start sampling after 12 hours of fermentation, and then take samples every 4 hours to test the liquefaction power and saccharification power of the sample. When the liquefaction power of the sample is greater than or ...

Embodiment 3

[0034] Crush 200 parts of Qing Pinellia, 15 parts of alum, and 10 parts of Liushenqu into 80-mesh flour; mix with 8 parts of ginger juice and 40 parts of flour to obtain a fermentation substrate. Add an appropriate amount of water to adjust the water content of the fermentation substrate to 65%.

[0035] The fermentation substrate is sterilized at low temperature by pasteurization.

[0036] Mix the compound bacterial agent III with the fermentation substrate at a mass ratio of 1:60, and cut into small pieces or make coarse particles under aseptic conditions. The diced or granulated fermentation substrate is placed in a fermentation box for fermentation, and the temperature in the fermentation box is kept at 35° C. and the relative humidity is kept at 85%.

[0037] Start sampling after 12 hours of fermentation, and then take samples every 4 hours to test the liquefaction power and saccharification power of the sample. When the liquefaction power of the sample is greater than o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com