Drainer downpipe mounting structure

A technology for installing structures and downpipes, applied to expansion compensation devices for pipelines, pipe components, pipes/pipe joints/fittings, etc., can solve problems such as weld tearing, desoldering or extrusion deformation, gas leakage, etc. Achieve the effect of avoiding pipe blockage, avoiding weld tearing and ensuring service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

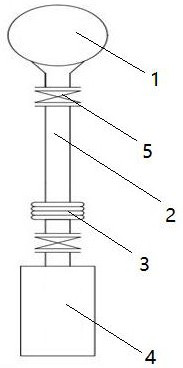

[0020] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on the specific embodiments and in conjunction with the accompanying drawings.

[0021] This embodiment provides a drainer downpipe installation structure, including a gas pipeline 1 arranged along the horizontal direction, a downpipe 2 is fixed and welded vertically at the lower end of the gas pipeline 1 , and the lower end of the downpipe 2 is welded to the drainer 4 . The water in the gas pipeline 1 can flow into the drainer 4 through the downspout 2 and be discharged by the drainer 4 .

[0022] A corrugated expander 3 is fixedly installed on the downspout 2 , and the axis of the corrugated expander 3 coincides with the axis of the downspout 2 . The expansion and contraction of the downpipe 2 can compensate for the length change caused by thermal expansion and contraction through the expansion and contraction of the corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com