Low-quality emptying steam power generation system

A power generation system, low-quality technology, applied in steam engine devices, machines/engines, sustainable manufacturing/processing, etc., can solve problems such as energy waste, aggravating the greenhouse effect, and difficulty of low-quality steam, so as to protect the environment and improve energy conservation horizontal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

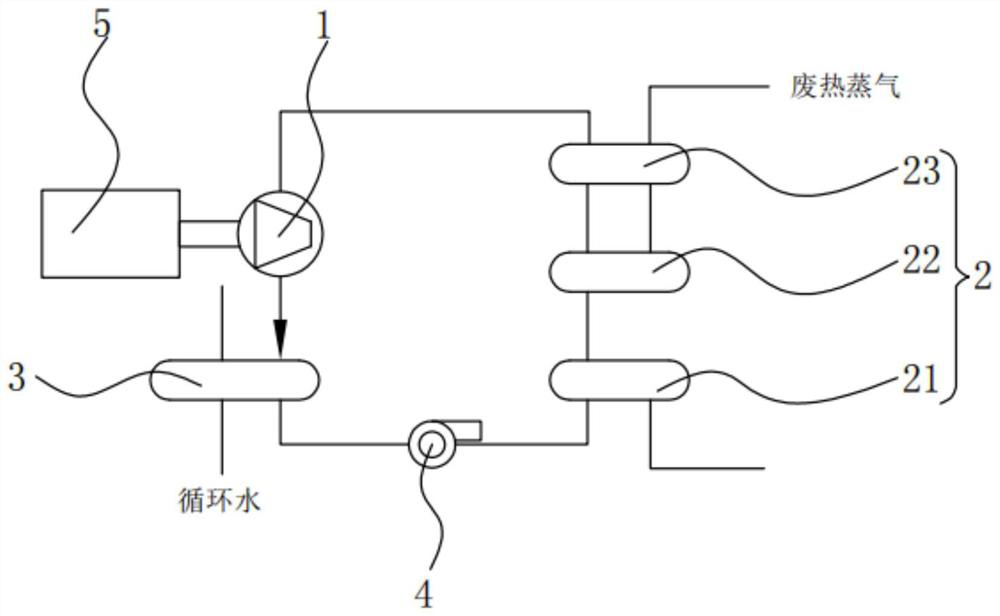

[0037] Please refer to figure 1 ,in, figure 1 It is a structural schematic diagram of the first embodiment of the low-quality vented steam power generation system provided by the present invention. Low-quality vented steam power generation system includes: steam turbine 1;

[0038] A heat exchange system 2, the heat exchange system 2 is arranged at the inlet of the steam turbine 1 for sufficient heat exchange between the low-temperature heat source and the organic working medium, and the heat exchange system 2 includes a preheater 21 and an evaporator 22 and a superheater 23, the output end of the preheater 21 is connected to the input end of the evaporator 22 through a pipeline, and the output end of the evaporator 22 is connected to the input end of the superheater 23 through a pipeline;

[0039] A condenser 3, the condenser 3 is connected to the outlet of the steam turbine 1 through a pipeline;

[0040] A working fluid circulation pump 4, the working fluid circulation pu...

no. 2 example

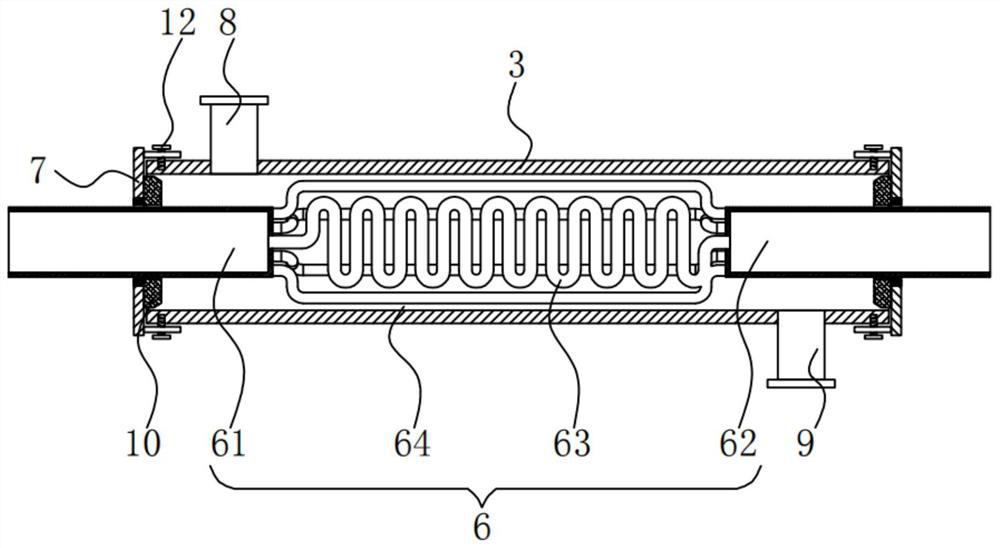

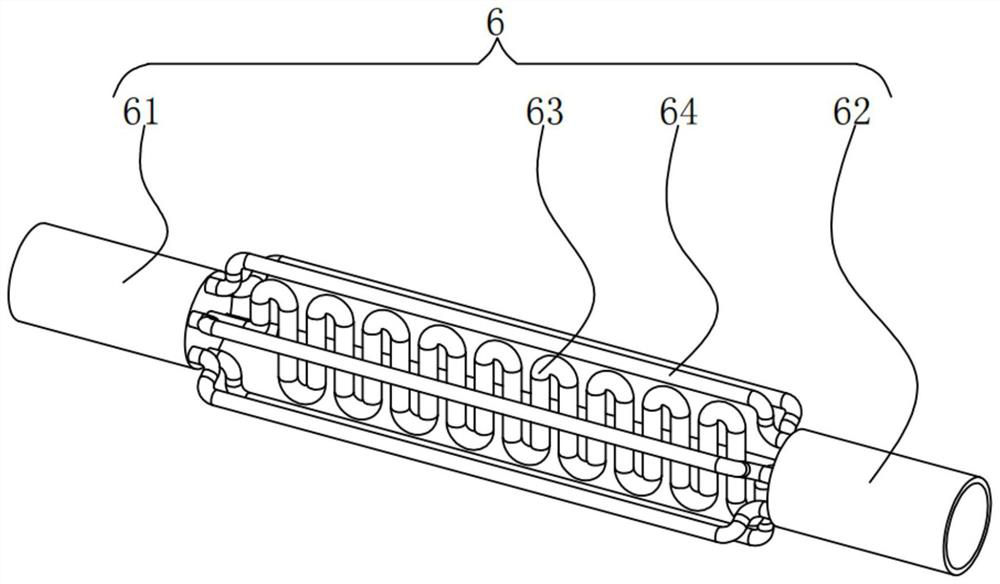

[0051] Please refer to Figure 2-5 , based on the power generation system based on low-quality vent steam provided in the first embodiment of the present application, the second embodiment of the present application proposes another power generation system based on low-quality vent steam. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0052] Specifically, the difference of the power generation system based on low-quality vented steam provided by the second embodiment of the present application is that the power generation system based on low-quality vented steam also includes a circulating water cooling system 6 arranged on the condenser 3, so The circulating water cooling system 6 includes a water inlet pipe 61 and a water outlet pipe 62, a revolving central pipe 63 is fixedly connected between the center of the water inlet pipe 61 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com