Fabricated energy dissipation extension arm structure system

A prefabricated and systematic technology, applied in building components, protective buildings/shelters, building types, etc., can solve problems such as not being able to meet requirements well, and achieve the effect of controlling repair costs and reducing structural damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

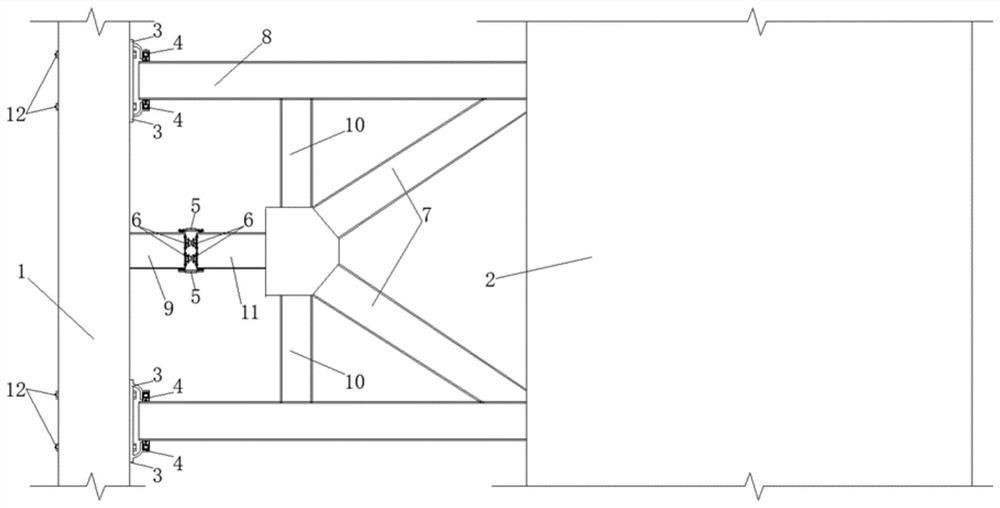

[0044] see figure 1 , this embodiment is an assembled energy-dissipating outrigger structure system, including a frame column 1, a core tube 2, a leaf spring connector 3, an energy-dissipating shock absorber 4, a miniature buckling-resistant support 5, and a leaf spring viscoelastic damper 6 , Diagonal brace 7, I-beam I8, overhanging steel member 9, vertical support 10, I-beam II11 and column bolt 12.

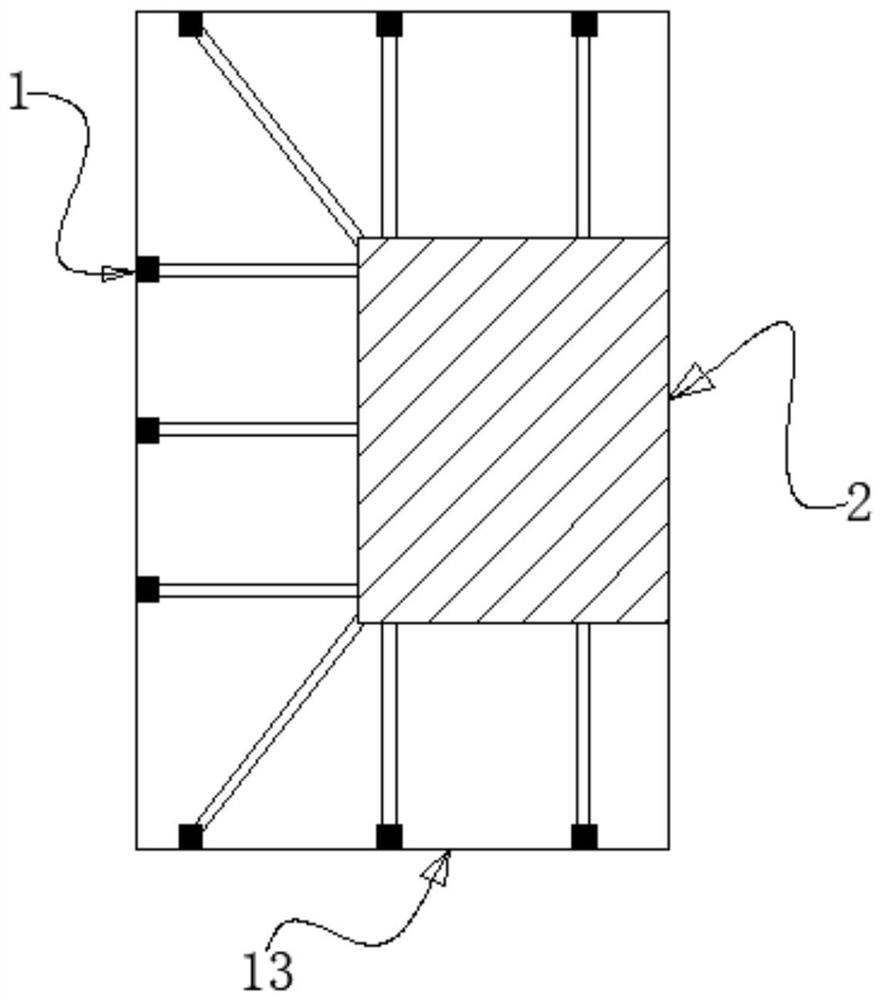

[0045] see figure 2 , the core tube 2 is an offset core tube, and uneven deformation easily occurs between the core tube 2 and the frame column 1 .

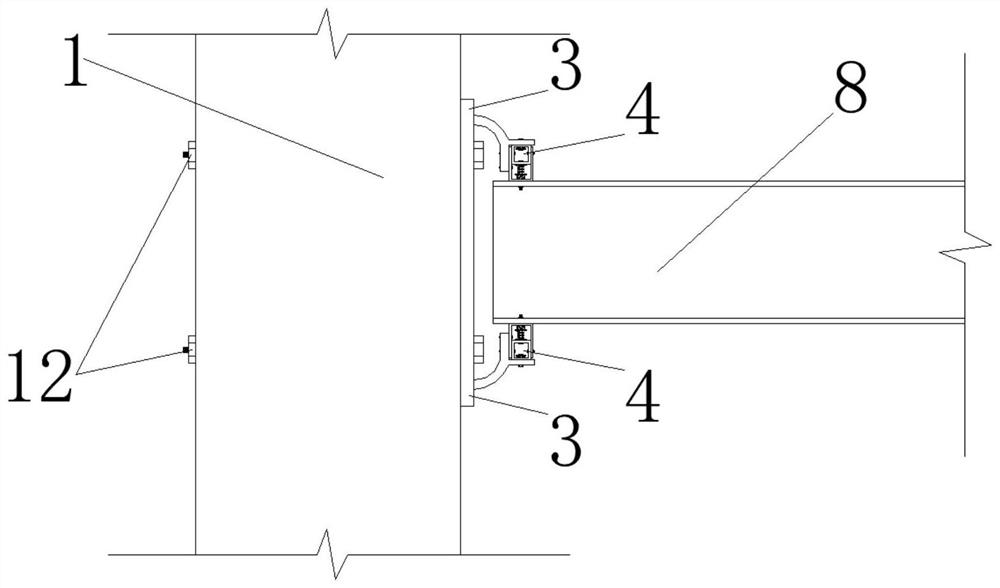

[0046] see image 3 and Figure 4 , The frame column 1 is connected to the leaf spring connector 3 through the column bolt 12, and the leaf spring connector 3 is connected to the I-beam I8 through the energy dissipation shock absorber 4.

[0047] The energy dissipation shock absorber 4 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com