Anti-slag-blocking slag discharging opening structure for entrained-flow bed gasification furnace and arrangement method thereof

A technology of gasifier and entrained bed, which is applied in the field of slag opening structure and its arrangement for preventing slag clogging in entrained bed gasification furnace, which can solve problems such as production line outage, economic loss of enterprises, slag clogging, etc., and achieve slag temperature high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0049] One adopts the traditional slag outlet, with a gas production capacity of 80,000Nm 3 / h gasifier, a slag blocking accident occurred during operation. Due to the slow judgment, the processing time was delayed, the slag outlet was completely blocked, and the furnace was forced to stop. Since the gasifier is the production source of chemical enterprises, the shutdown of the gasifier resulted in the shutdown of the entire production line. The gasifier was shut down for 8 days to remove slag in one year, and the economic loss of the entire coal gasification production line was more than 60 million yuan.

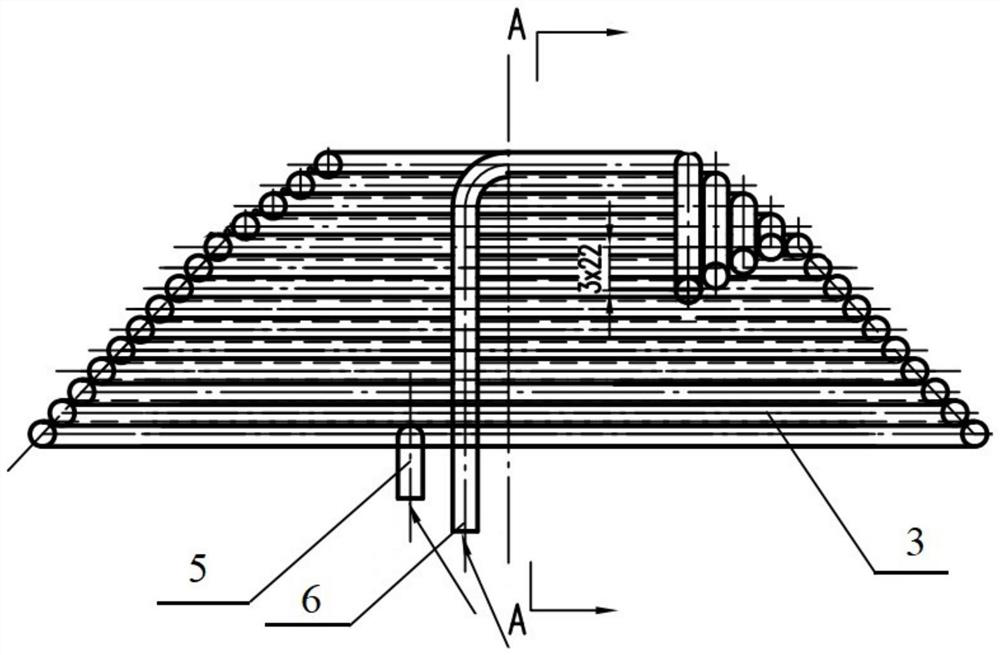

[0050] Also with a gas production capacity of 80000Nm 3 / h gasifier as an example, the structure of the lower slag port adopts the structure described in this application, and the specific structural parameters are as follows:

[0051] The gas production capacity is 80000Nm 3 / h The bottom of the gasifier is processed with a circular platform-shaped lower slag port 2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com