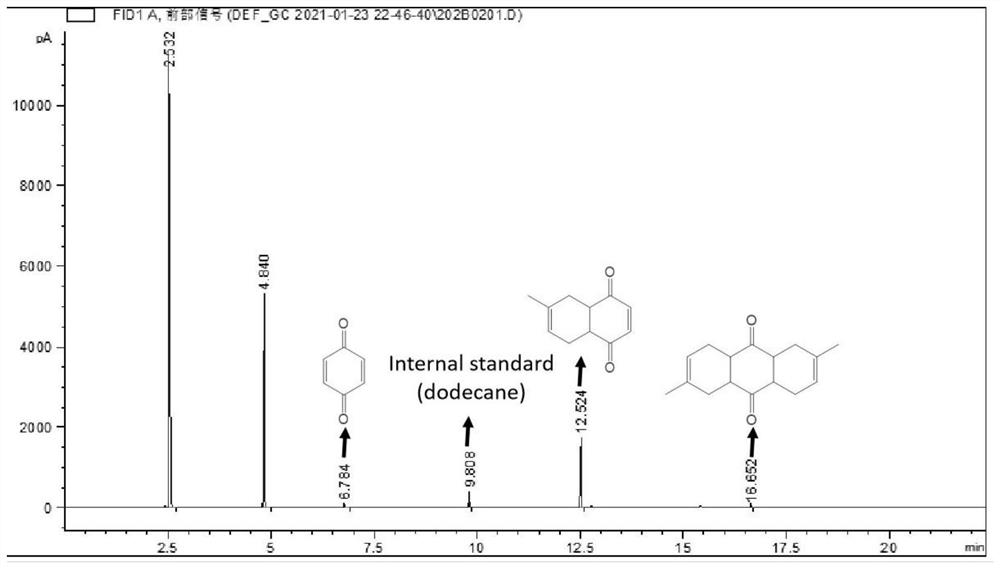

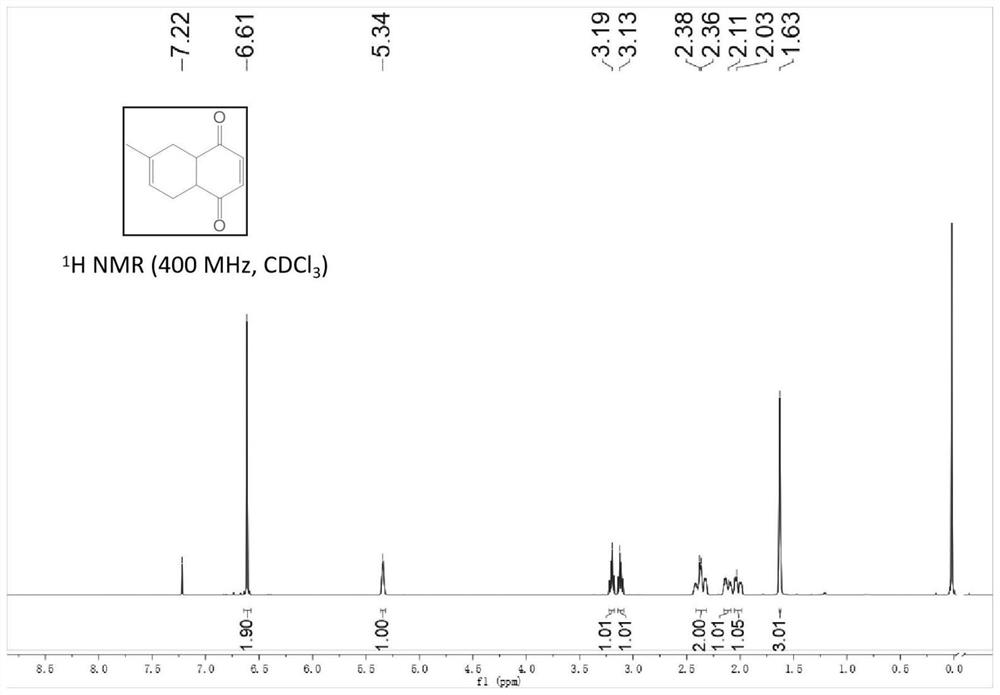

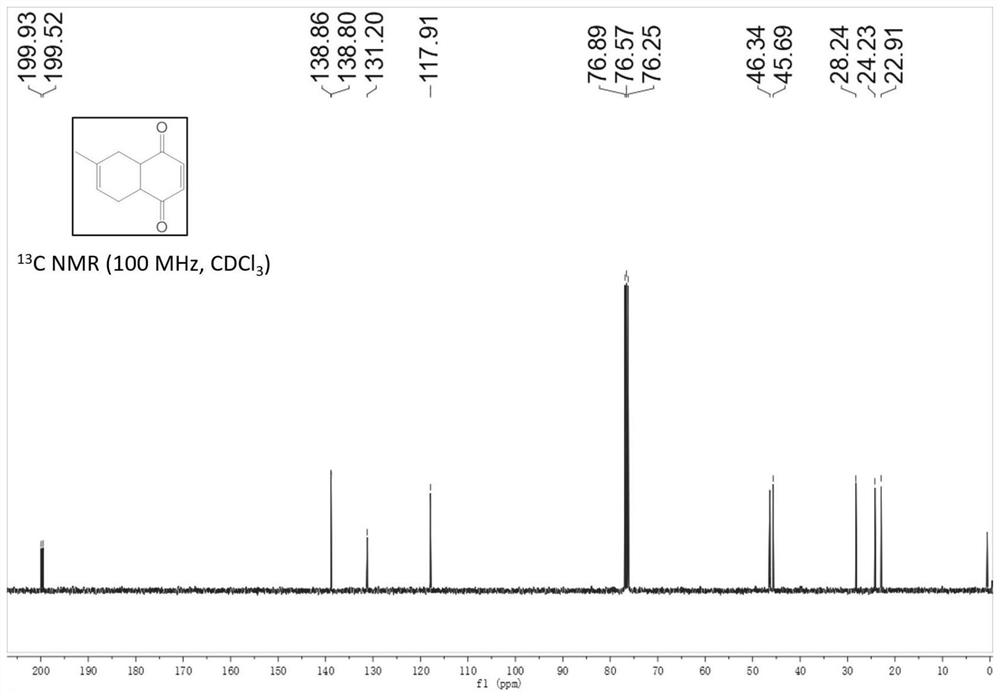

Method for synthesizing high-density aviation kerosene from biomass diene and p-benzoquinone in one pot

A technology of aviation kerosene and p-benzoquinone, which is applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., to achieve the effects of low cost, convenient preparation, and reduced product loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described below with specific examples, but the protection scope of the present invention is not limited to these examples.

[0043] In the following examples, the bifunctional catalyst is an example of Pd / H-β with a metal loading of 5%, and the preparation method is as follows: prepare PdCl with a mass concentration of 10wt% 2 Add 2g of H-β molecular sieve to 2g of aqueous solution, add an appropriate amount of water to impregnate with equal volume, the metal loading in the catalyst after loading is 5wt%, and then stand at room temperature for 12 hours, dry at 100°C for more than 10 hours, and then dry at 550 Roast in air atmosphere at ℃ for 4 hours, reduce with hydrogen gas (60% volume concentration) at 300℃ for 4 hours, and finally pass through nitrogen gas containing 1% oxygen by volume concentration for 4 hours after the temperature drops to room temperature. Referring to the above method, the loading amount of Pd, the active metal com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com