Method and system for producing vehicle fuel from waste plastic

A technology for waste plastics and vehicle production, which is used in hydrocarbon oil treatment products, preparation of liquid hydrocarbon mixtures, and petroleum industry. High effect, good environmental benefit, high solvent recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

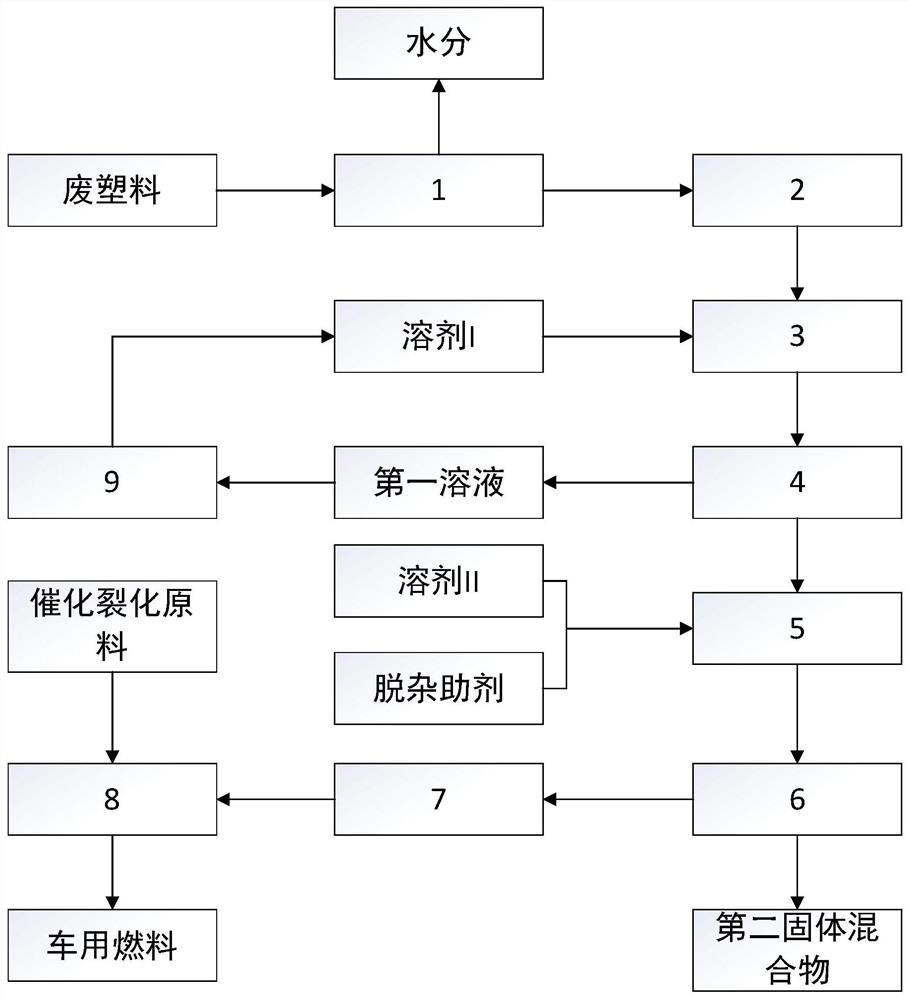

Method used

Image

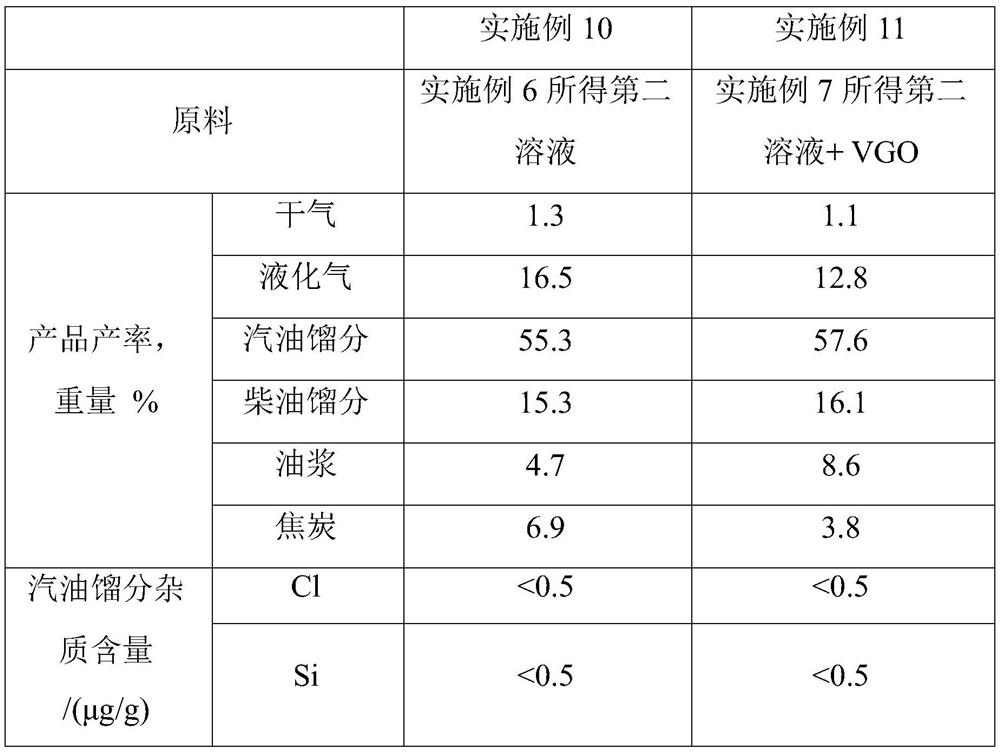

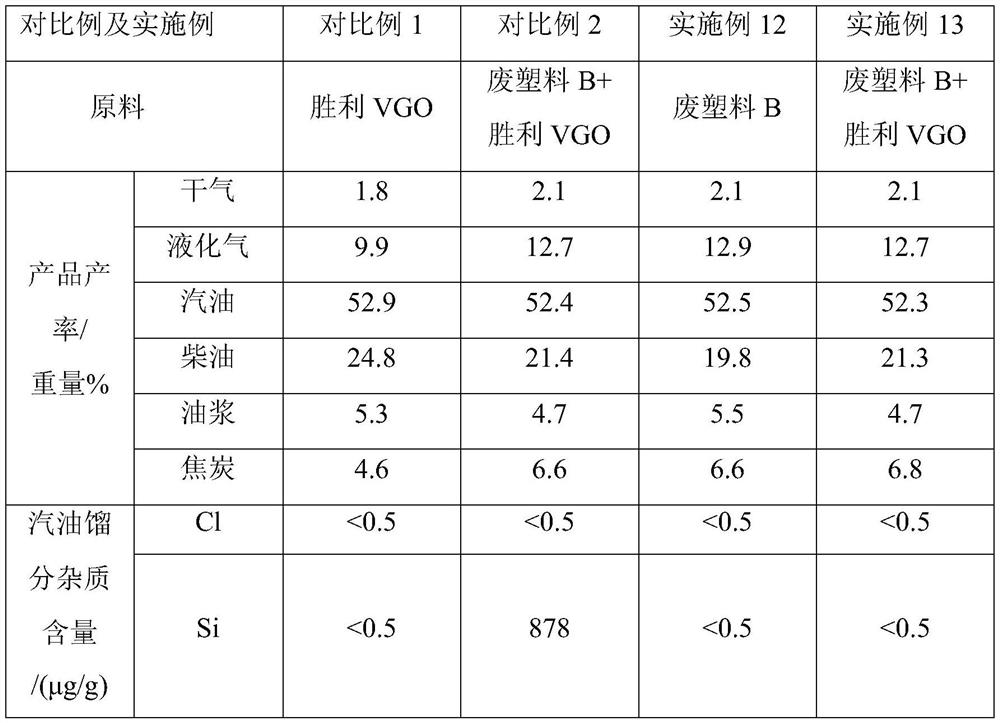

Examples

Embodiment 1~5

[0072] Waste plastic A is a commercially available mixture mixed according to the ratio of PE:PP:PS:PVC=10:5:1:1.5, wherein PE, PP, and PVC are in the form of film, and PS is in the form of foam. Crushed to <50mm, the broken particles of waste plastic A and solvent I preheated to 65°C enter the first decontamination unit of waste plastic, and are fully mixed and dissolved at 65°C. °C separated into a first solution and a first solid mixture.

Embodiment 1

[0073] The solvent I used in Example 1 is tetrahydrofuran, and the weight ratio of solvent I to waste plastic A is 10:1; the chlorine content in the obtained first solid mixture is 23 μg / g.

Embodiment 2

[0074] The solvent I used in Example 2 is methyl ethyl ketone, and the weight ratio of solvent I to waste plastic A is 10:1; the chlorine content in the obtained first solid mixture is 25 μg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com