Method for preparing 5-hydroxymethylfurfural

A technology of hydroxymethylfurfural and II-2, which is applied in the field of preparing 5-hydroxymethylfurfural, can solve the problems of poor HMF selectivity, low yield, and many by-products, and achieve simple process, low cost, The effect of reducing the production of by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

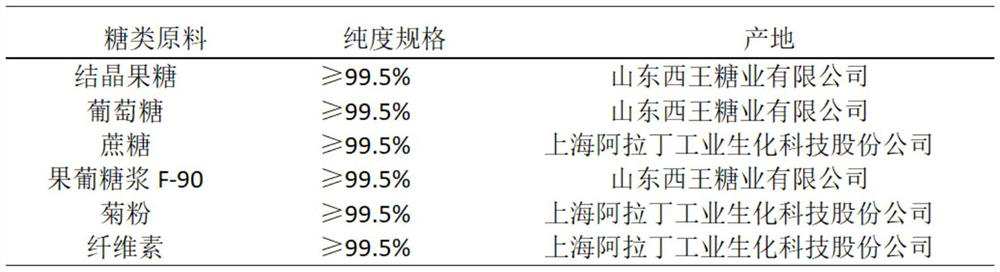

Examples

Embodiment 1

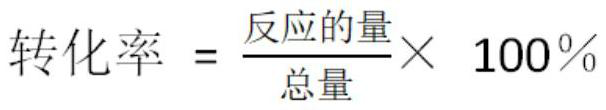

[0060] In the reactor, put the prepared potassium chloride: water = 3:1 salt solution into the reactor, heat to 80°C, stir evenly, add crystalline fructose: salt solution: Nafion-H solid acid catalyst = 10:3 :0.1. During the reaction process, heat and stir to make the system materials fully contact.

[0061] The pressure of the reaction system was adjusted, the reaction temperature was 80° C., and the reaction time was 5 h.

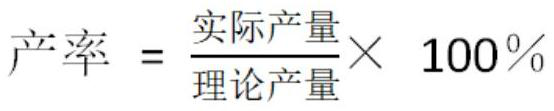

[0062] pressure sugar conversion rate HMF reaction yield -0.015 100% 78.3% -0.025 100% 78.5% -0.035 100% 79.8% -0.045 100% 85.5% -0.04 100% 92.3% -0.065 100% 97.5% -0.075 100% 95.7% -0.08 100% 90.8% -0.085 100% 87.3% -0.095 100% 83.1% -0.1 100% 80.1%

Embodiment 2

[0064] In the reactor, put the prepared potassium chloride: water = 3: 1 salt solution into the reactor, heat to 80 ° C, stir evenly, add crystallized fructose: salt solution: Nafion-H solid acid catalyst = 10: 3 : 0.1. During the reaction process, heat and stir to make the system materials fully contact.

[0065] The pressure of the reaction system in the first stage was adjusted, the reaction temperature was 80° C., and the reaction time was 1 h.

[0066] The pressure of the reaction system in the second stage was adjusted, wherein the reaction temperature was 80° C., and the reaction time was 4 h. Detection of sugar conversion rate and HMF reaction yield.

[0067] first stage pressure second stage pressure sugar conversion rate HMF reaction yield -0.015 -0.045 100% 79.1% -0.025 -0.055 100% 79.5% -0.035 -0.065 100% 94.6% -0.045 -0.075 100% 84.1% -0.045 -0.08 100% 84.9% -0.045 -0.095 100% 82.5% -0.025 -0.065 10...

Embodiment 3

[0069] In the reactor, put the prepared salt: water = 3: 1 salt solution into the reactor, heat to 80 ° C, stir evenly, add crystallized fructose: salt solution: Nafion-H solid acid catalyst = 10: 3: 0.1 . During the reaction process, heat and stir to make the system materials fully contact.

[0070] Adjust the pressure of the reaction system to -0.035 MPa, the reaction temperature to 80° C., and the reaction time to 1 h.

[0071] The pressure of the reaction system in the second stage was adjusted to -0.075MPa, the reaction temperature was 80°C, and the reaction time was 4h.

[0072] Salt sugar conversion rate HMF reaction yield Sodium chloride 100% 97.50% calcium chloride 100% 90.50% sodium sulfate 100% 91.30% potassium bromide 100% 94.10% magnesium sulfate 100% 94.30% lithium carbonate 100% 92.20% Tetraethylammonium bromide 100% 95.60% Tetrabutylammonium chloride 100% 95.90% 1-Ethyl-3-methylimidazol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com