Stress annealing device for glass bottle production

A technology for stress annealing and glass bottles, applied in the field of stress annealing devices for glass bottle production, can solve the problems of large volume of glass bottles, affecting the annealing quality of glass bottles, and differences in cooling rates inside and outside the glass bottles, and achieve the effect of improving annealing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

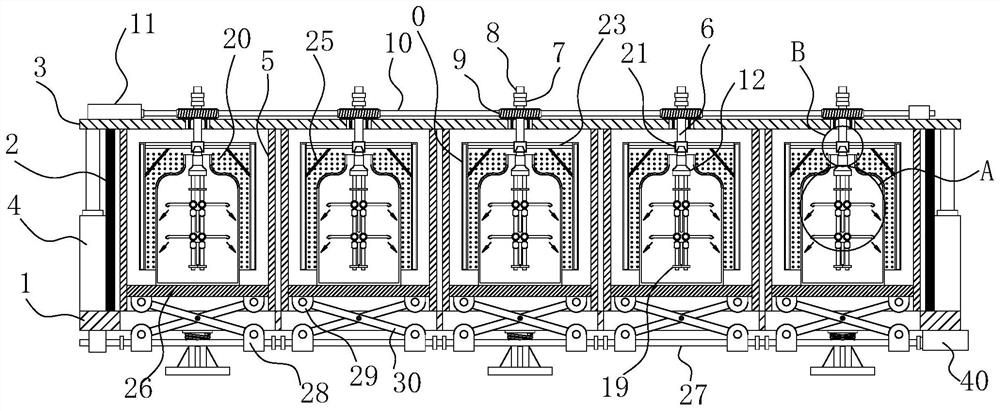

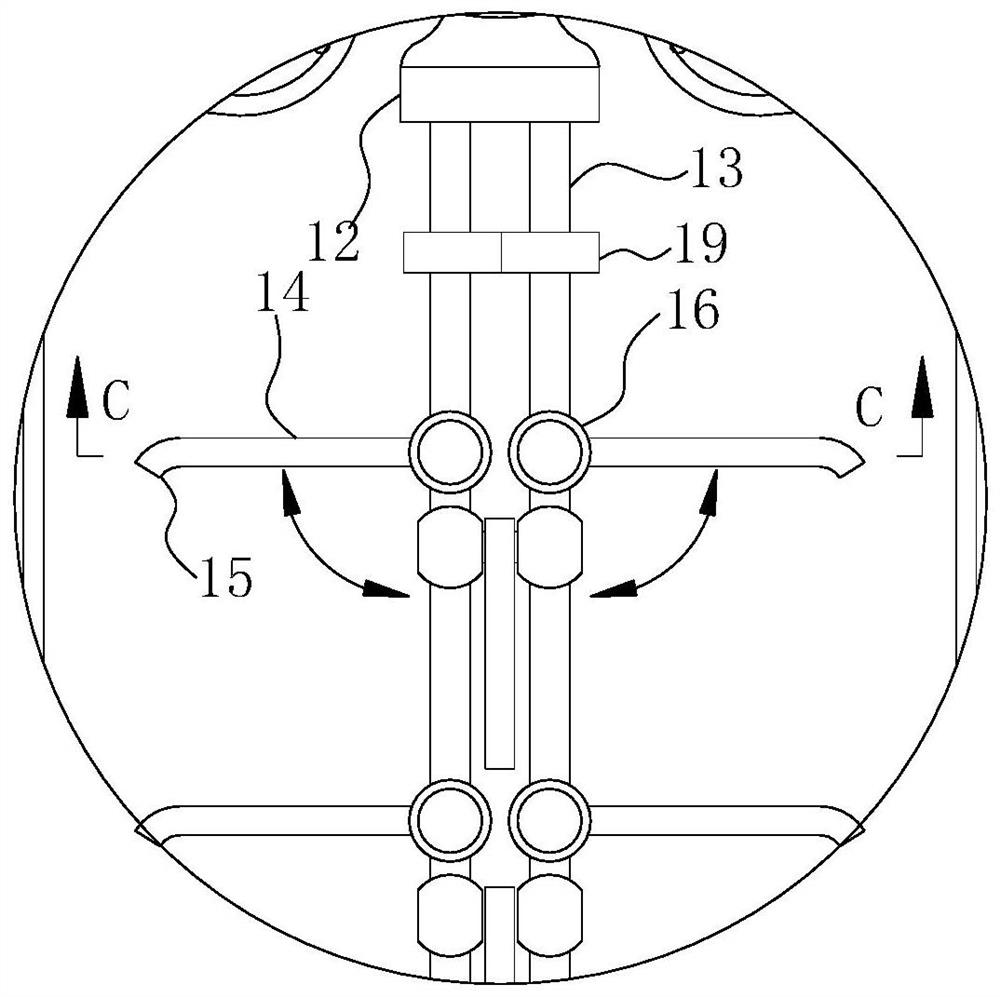

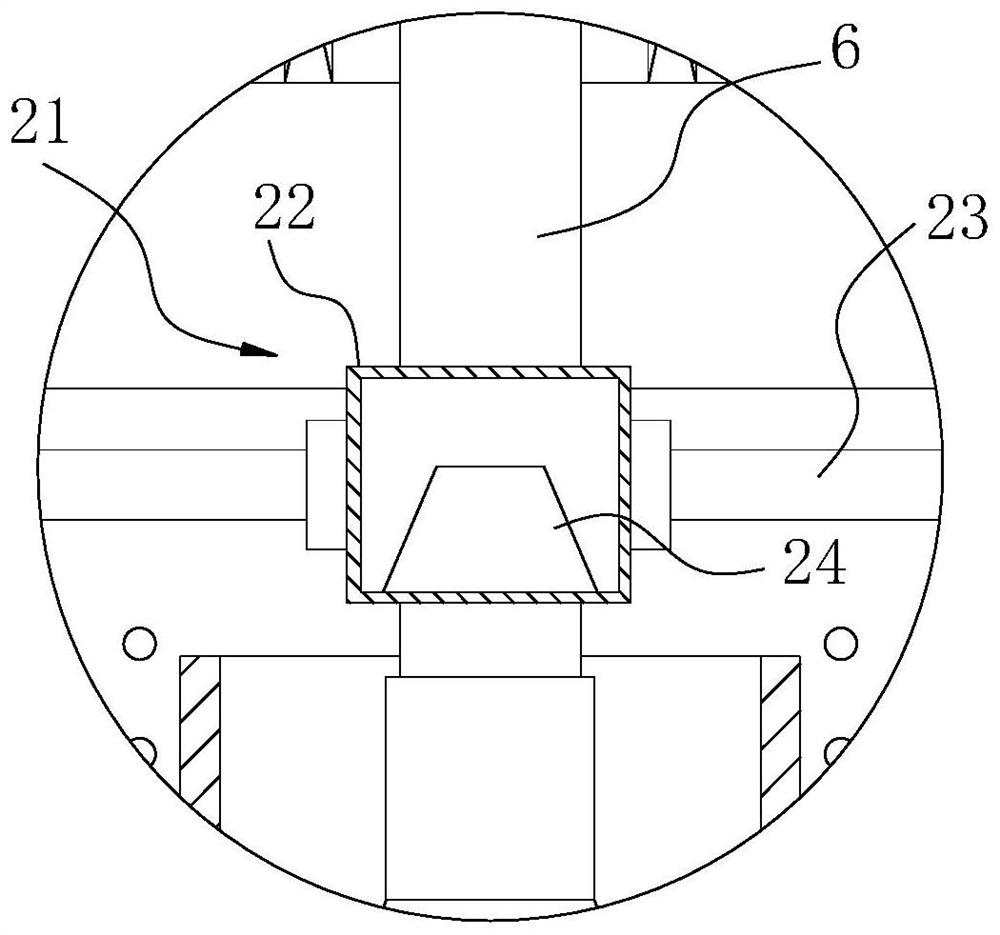

[0024] Such as Figure 1-5 As shown, a stress annealing device for the production of glass bottles includes a shell, and the shell is an insulating shell. The shell includes an insulating bottom plate 1, an insulating side plate 2 and an insulating top plate 3. The construction method of the insulating structure is relatively conventional. Generally, the inner surface of the steel plate can be lined with refractory bricks. Of course, it is also feasible to use other insulation boards to build the outer shell. The thermal insulation base plate 1 and the thermal insulation side plate 2 of the present invention adopt an integrated structure, and the thermal insulation top plate 3 adopts an independent lifting structure. The two ends of the thermal insulation base plate 1 are provided with vertical lifting hydraulic cylinders 4, and the output of the lifting hydraulic cylinders 4 The end faces upwards and is connected with the insulation top plate 3. The lifting hydraulic cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com