Processing device for iron-based amorphous alloy strip

An iron-based amorphous alloy and processing device technology, which is applied in the fields of coiling strips, transportation and packaging, and cleaning methods using tools, can solve problems such as real-time detection of density and reduced yield, and achieve economic cost savings , reduce losses, improve the effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

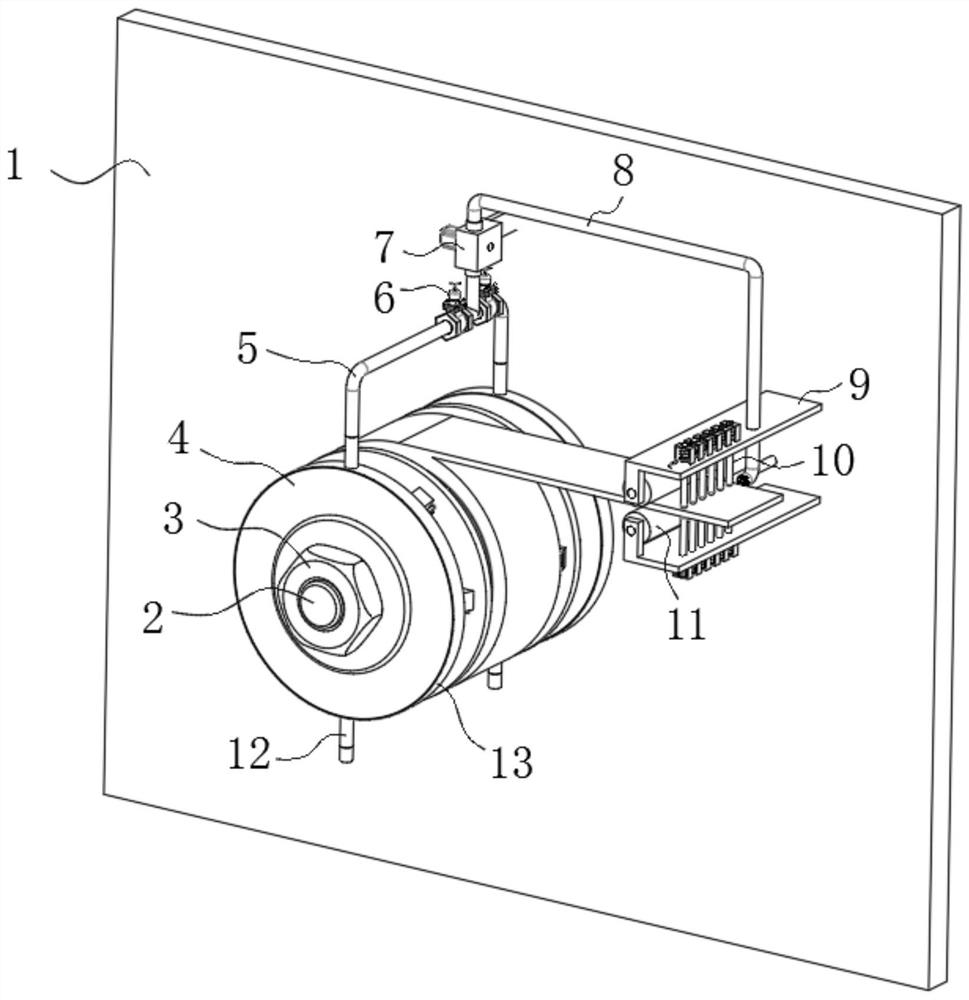

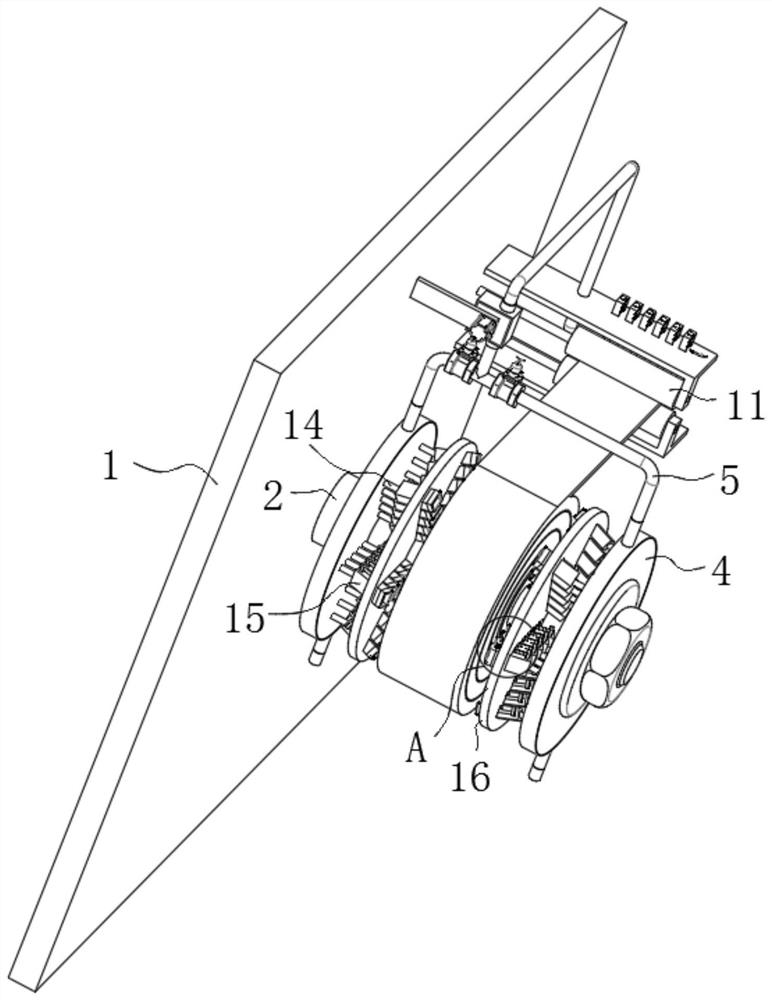

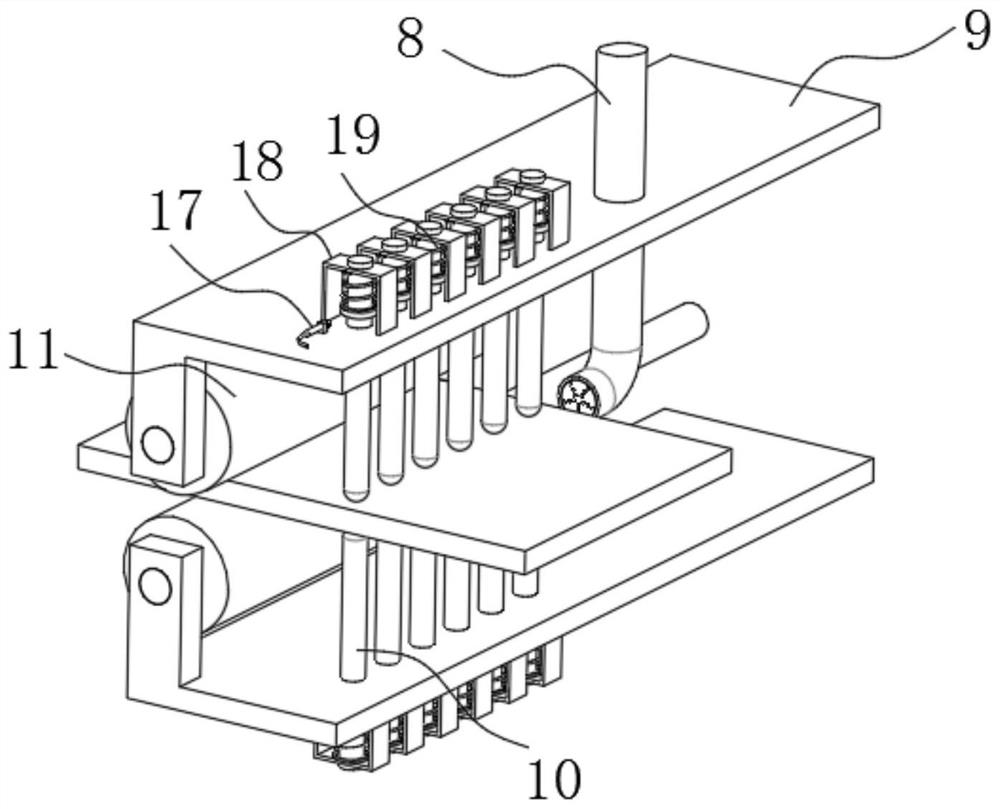

[0027] refer to figure 1 , 2 , 4, 5, a processing device for an iron-based amorphous alloy strip, including a housing 1, and also includes:

[0028] The center is wound with a processing shaft 2 of an iron-based amorphous alloy strip. The processing shaft 2 is rotatably connected to the housing 1, and the processing shaft 2 is controlled by a driving motor to rotate. The processing shaft 2 is symmetrically installed with a second installation Plate 16, the iron-based amorphous alloy strip is located between two second mounting plates 16, each second mounting plate 16 is slidingly connected with a plurality of second ventilation short pipes 15, and the plurality of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com