Construction method capable of intelligently monitoring and alarming concrete compactness of tunnel lining in real time

A technology of intelligent monitoring and construction method, applied in tunnel lining, tunnel, wellbore lining and other directions, can solve the problems of poor construction quality of secondary lining, lowering of concrete integrity, and increased repair cost, etc., to achieve good promotion and application value, Reliable construction quality and the effect of strengthening construction process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

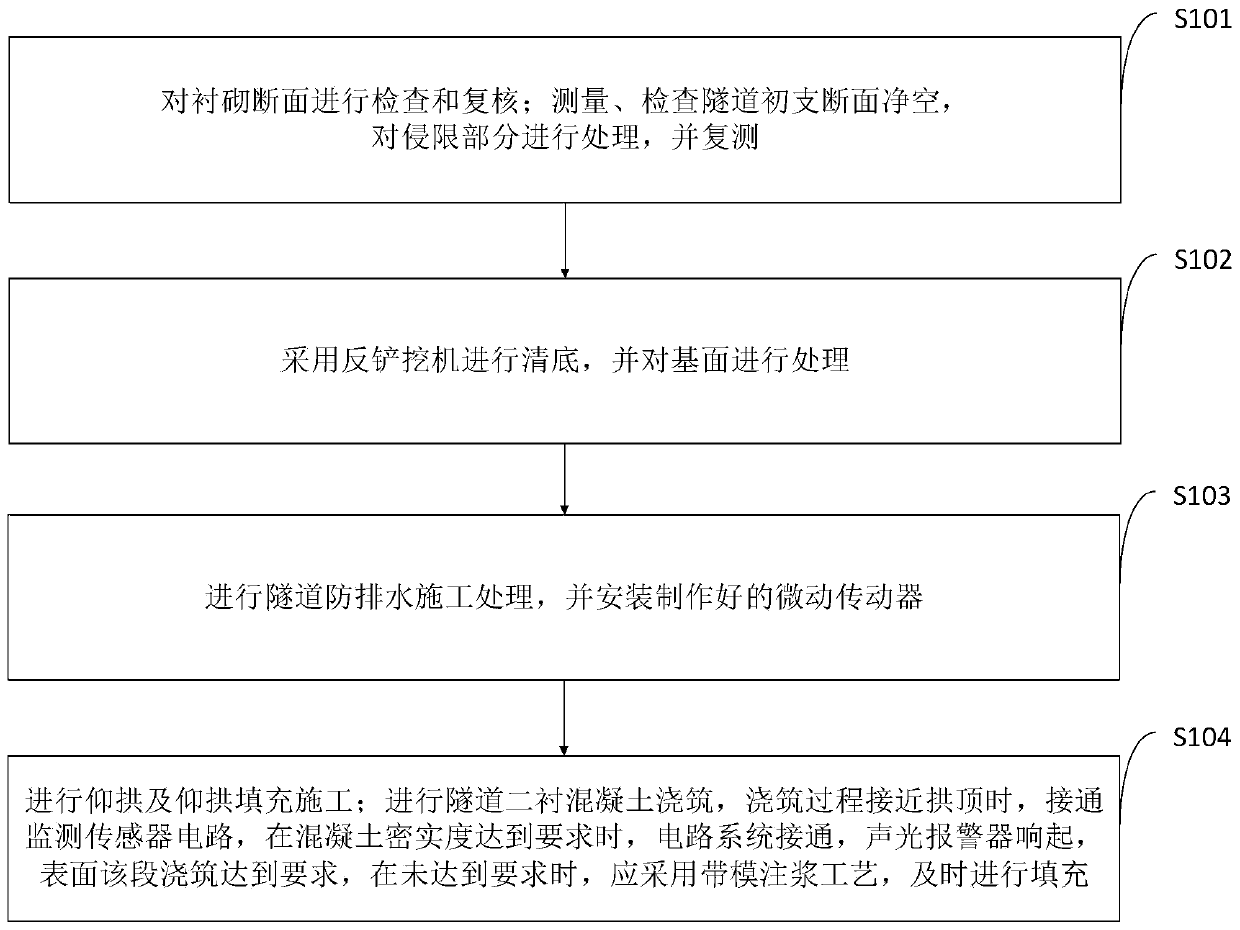

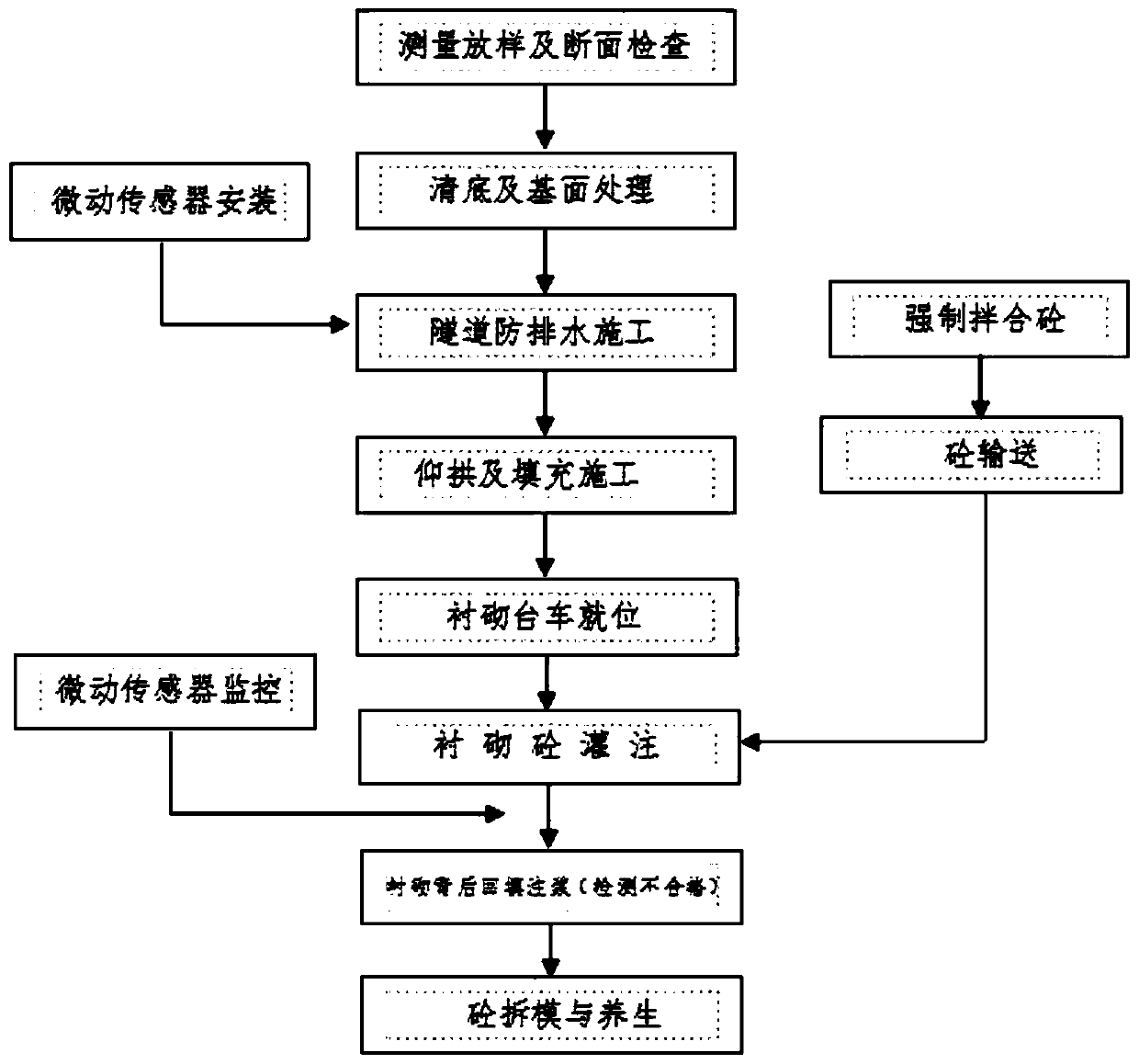

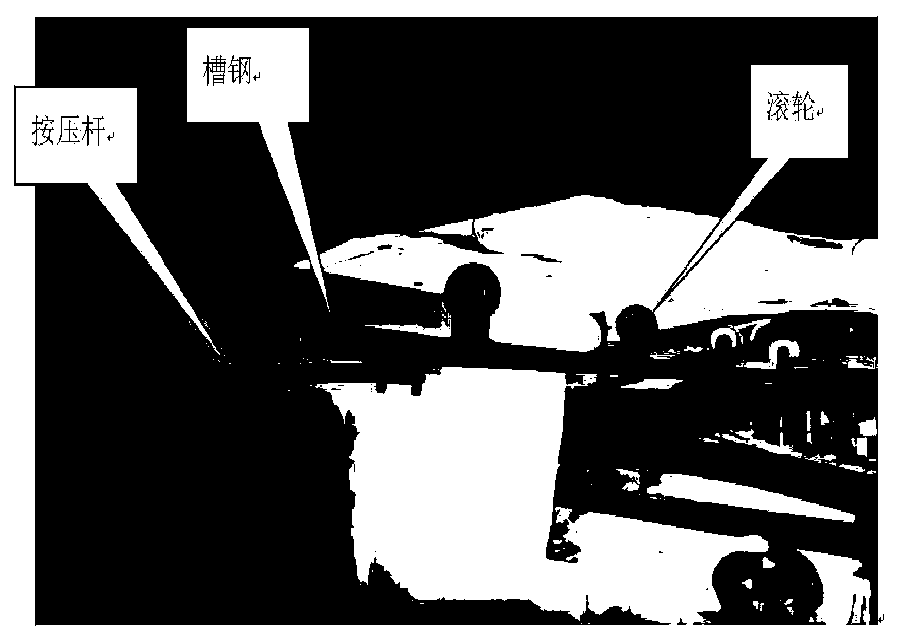

Method used

Image

Examples

Embodiment 1

[0084] 1. Background

[0085] Tunnel lining refers to a permanent support structure built with reinforced concrete and other materials along the periphery of the tunnel body in order to prevent the deformation or collapse of the surrounding rock. Relatively speaking, the secondary lining and the initial support refer to the inner lining built with concrete and other materials under the condition of the initial support of the tunnel to achieve the functions of reinforcement and support.

[0086] For tunnels constructed with the "New Austrian Method", the secondary lining acts as an integral part of the structural force to bear the pressure of the surrounding rock. The secondary lining of the tunnel is generally constructed with molded concrete. The main causes of voiding at the top of the secondary lining of the tunnel are construction technology, concrete shrinkage, and surrounding rock pressure. Among them, the improper construction technology and the degree and scope of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com