Mold for producing and processing automotive trim

A technology for car interiors and molds, which is applied to household appliances, other household appliances, cleaning methods and appliances, etc., can solve the problems of splashes and dust, increase the work intensity of staff, affect the health of staff, etc. Work intensity, easy disassembly and cleaning, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

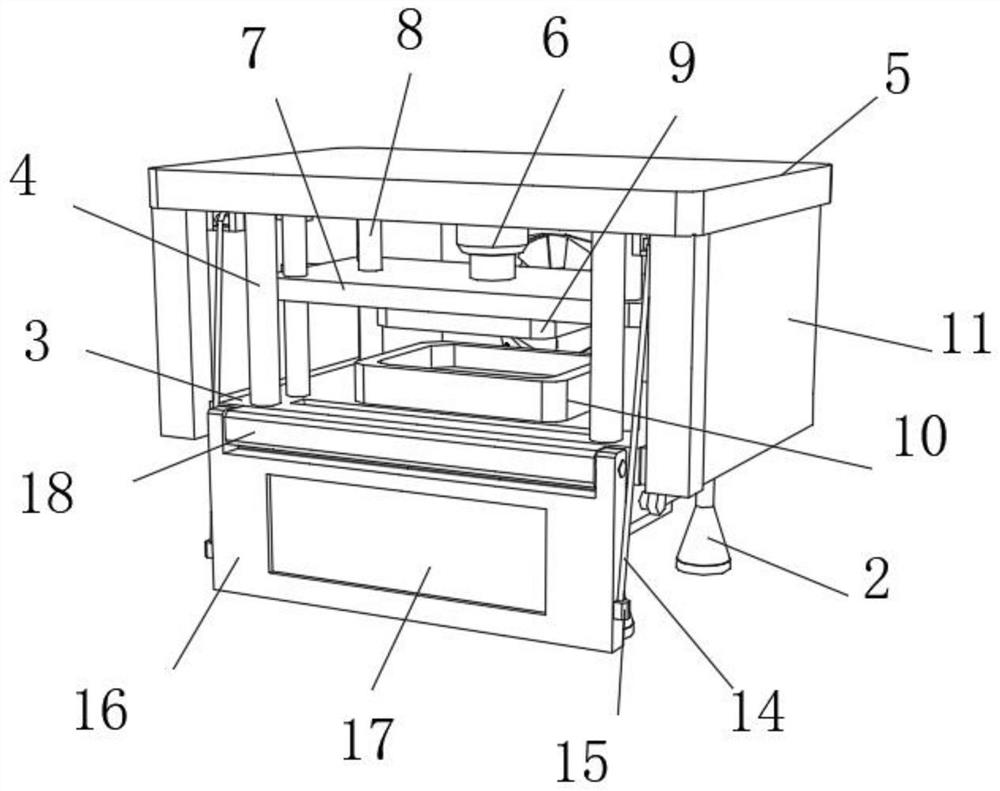

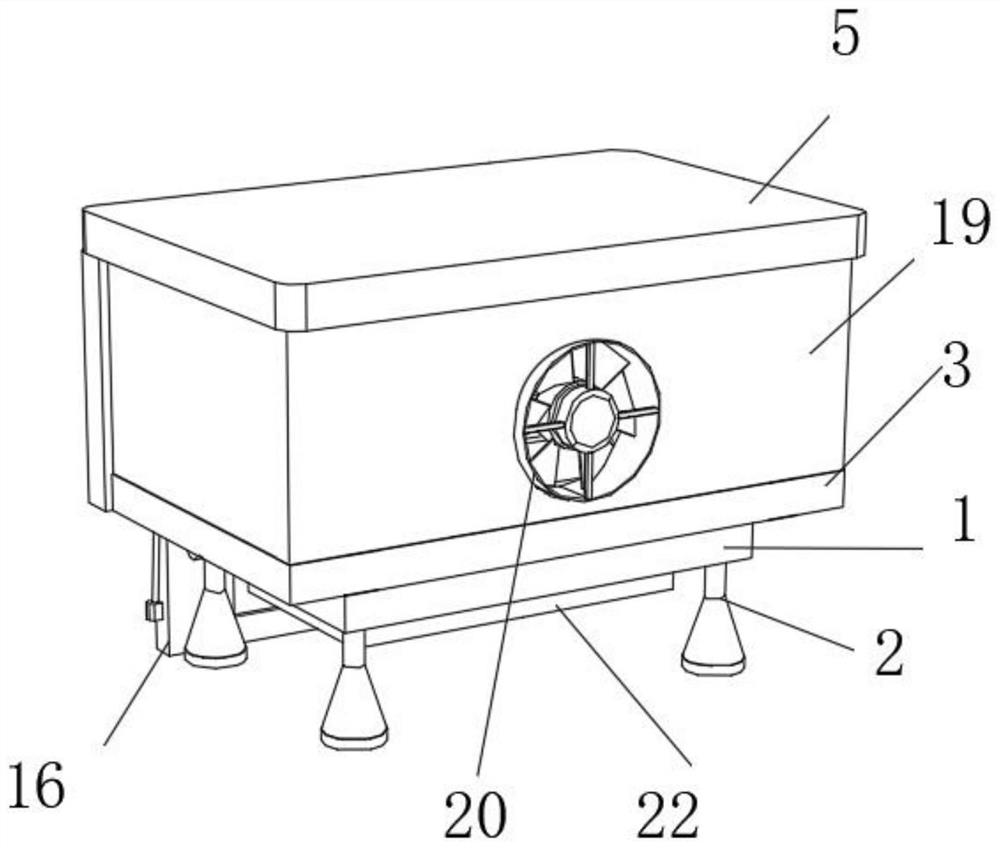

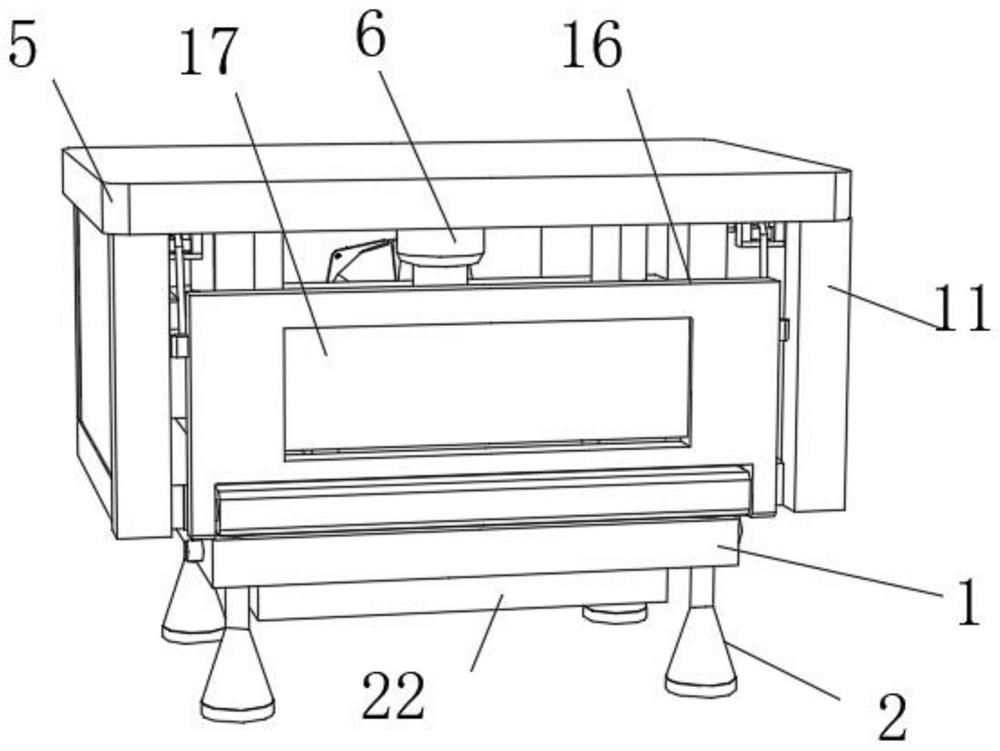

[0031] Such as Figure 1-7 As shown, the embodiment of the present invention provides a mold for the production and processing of automobile interior decoration, including a base 1, the four corners of the lower end of the base 1 are fixedly connected with a support seat 2, the support seat 2 plays a supporting role, and the top of the base 1 is fixedly connected with an operating Table 3, the four corners of the top of the console 3 are fixedly connected with columns 4, the tops of the columns 4 are fixedly connected with the lower end of the horizontal plate 5, the lower end of the horizontal plate 5 is fixedly connected with the cylinder 6, and the output end of the cylinder 6 is fixedly connected with a fixed plate 7, the lower end of the fixed plate 7 is fixedly connected with the movable mold 9, the top of the console 3 is fixedly connected with the fixed mold 10, and the operation of the starting cylinder 6 drives the movable mold 9 to contact with the fixed mold 10 to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com