High-precision inspection method for inner wall of wolteri-type X-ray focusing mirror

A detection method and high-precision technology, which is applied to measuring devices, instruments, and optical devices, can solve problems such as low efficiency, easy deformation, and poor precision, and achieve the effects of improving detection efficiency, ensuring low deformation, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

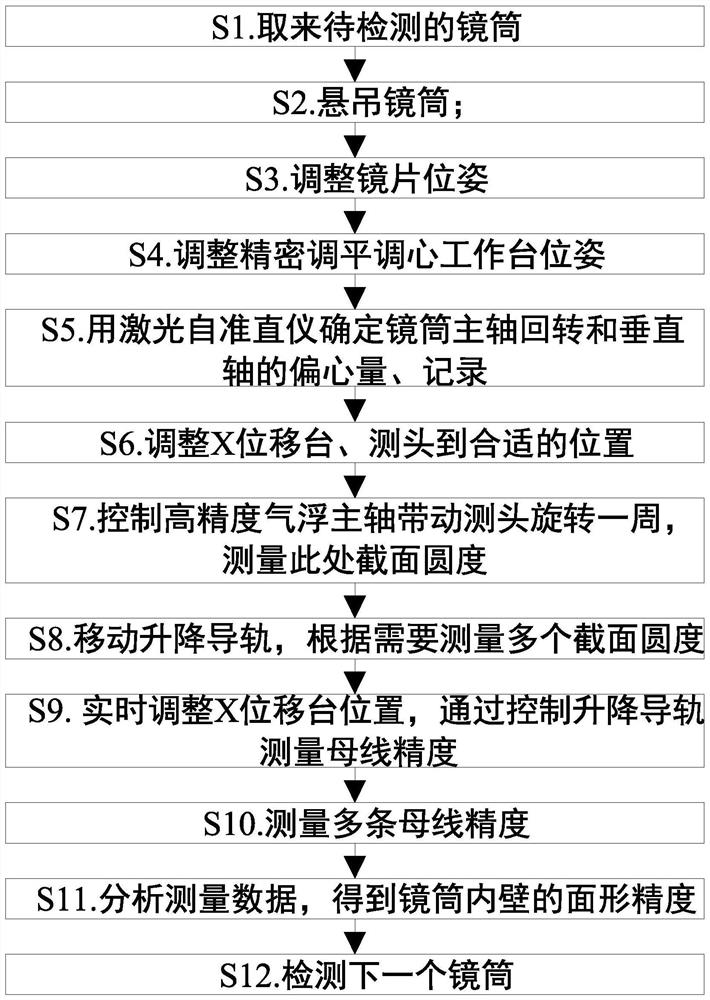

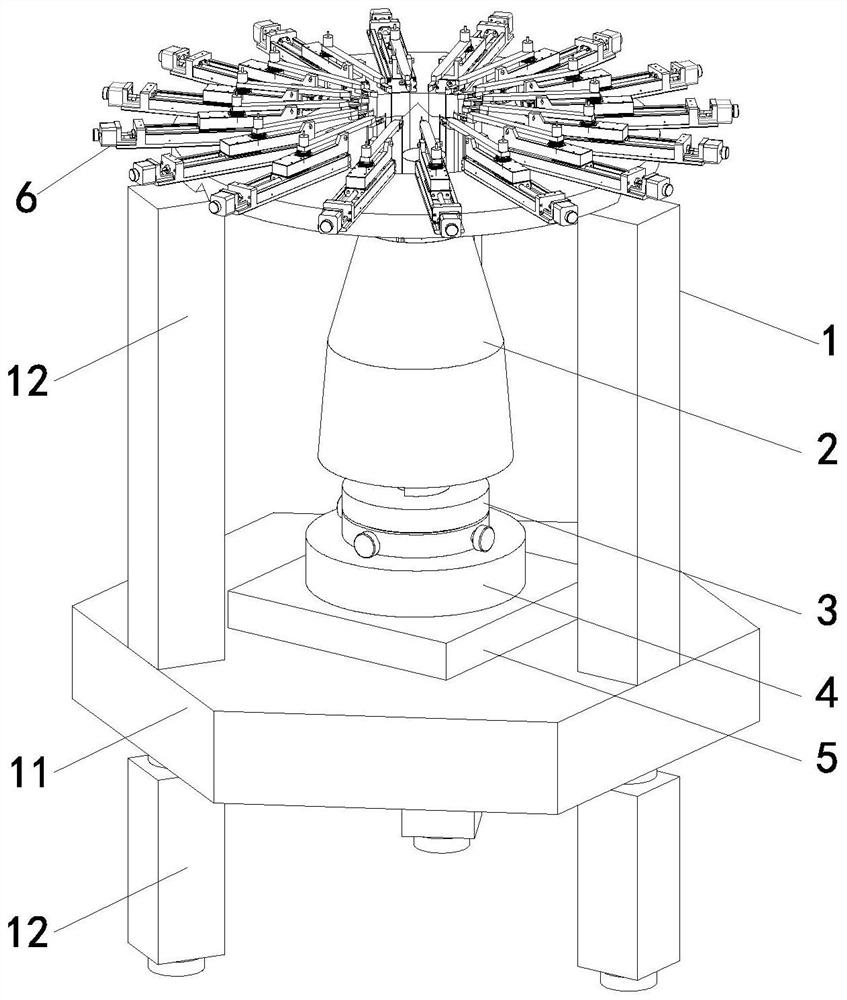

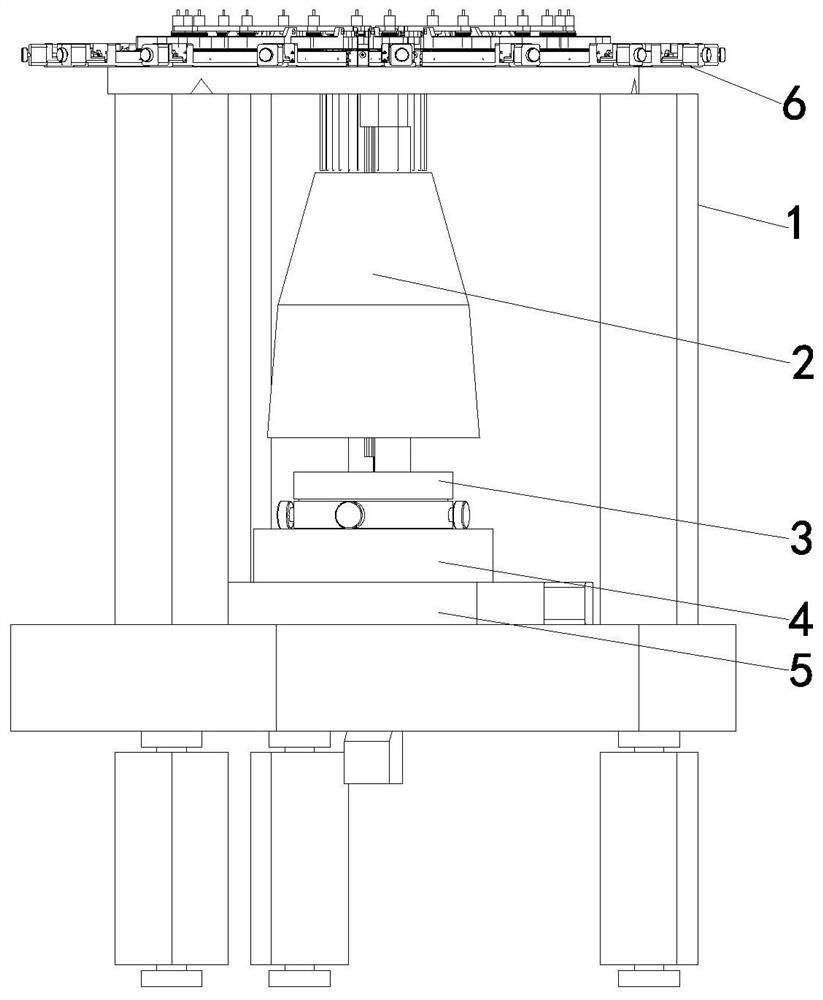

[0030] refer to figure 1 As shown, the high-precision detection method for the inner wall of the WolterI type X-ray focusing mirror comprises the following steps:

[0031] S1. Fetch the lens barrel 2 to be detected;

[0032] S2. suspending the lens barrel 2; realized by the active hoisting device 6 of the detection device;

[0033] S3. Adjust the position and posture of the lens barrel 2: adjust through the active lifting device 6 of the detection device;

[0034] S4. Adjust the 34 position and posture of the precision leveling and centering workbench: adjust through the XY translation platform 5 of the detection device;

[0035] S5. Turn off all light sources in the detection room, and use the laser autocollimator 312 to determine the eccentricity and record of the rotation of the main axis of the lens barrel 2 and the vertical axis;

[0036] S6. Adjust the X displacement stage 324, the long-distance interferometric probe 321 and the focusing short-distance interferometric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com