Underground excavation construction method for large-span column-free underground station

An underground station and underground excavation technology, used in underground chambers, earth-moving drilling, wellbore lining and other directions, can solve the problems of disturbance and damage, high construction risk control requirements, and increased roof covering soil load, etc., to achieve large bearing capacity and resistance. Deformation ability, safe and convenient large-area operation, and the effect of preventing stress release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

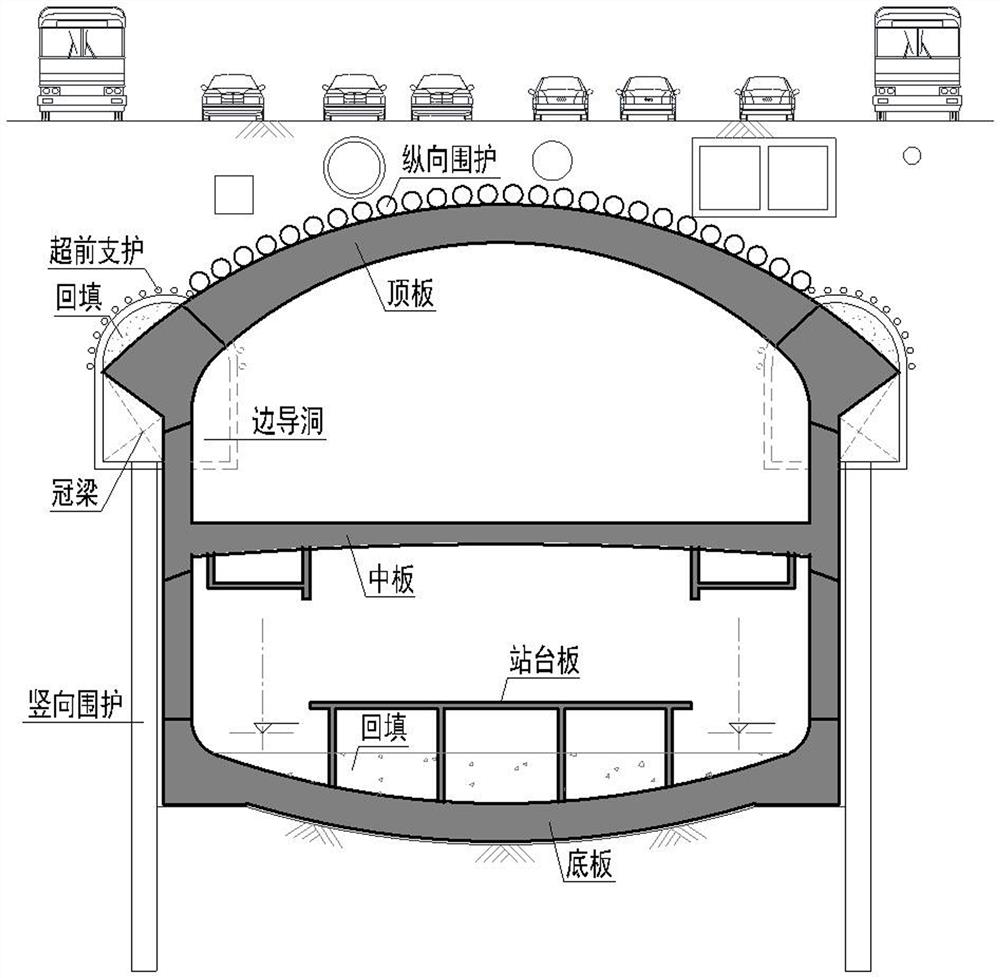

[0085] Take a standard-span double-storey column-free underground station as an example (see figure 1 ), the specific embodiments of the present invention are as follows:

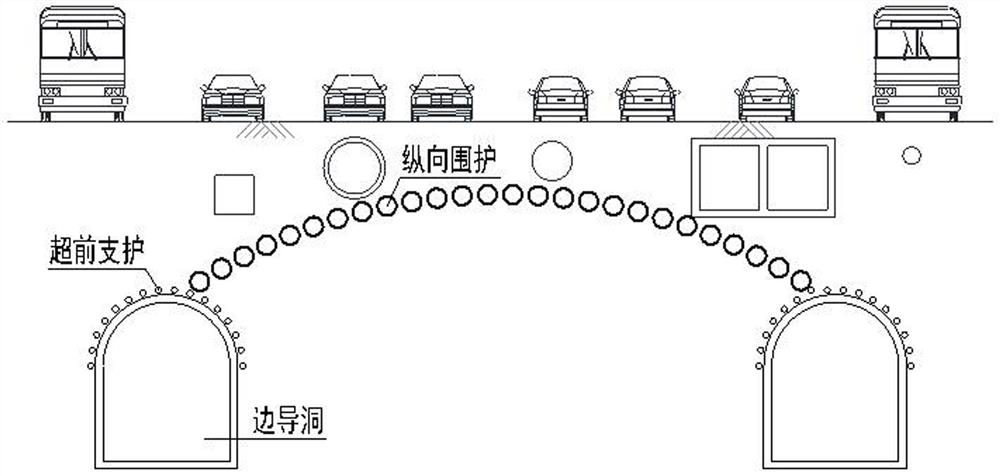

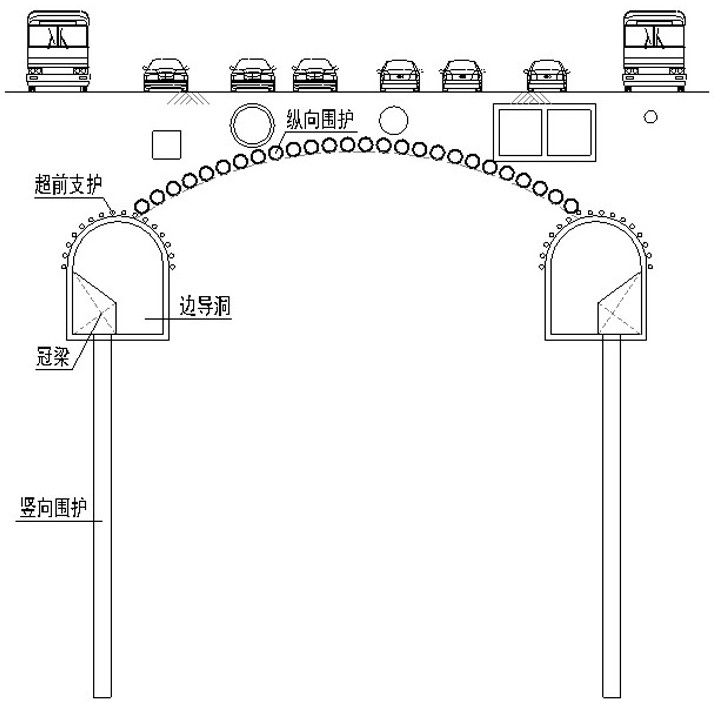

[0086] Such as figure 2 As shown, the steel pipe group is vertically jacked along the outer contour of the arch of the underground station in the shafts or cross passages at both ends of the underground station. The diameter of the steel pipe is determined according to the overlying load. Within 800mm, if necessary, the bearing capacity and anti-deformation capacity can be improved by inserting section steel, and self-compacting concrete is poured inside the steel pipe; the left and right side pilot tunnels are constructed longitudinally along the arch foot position, and the soil covering depth of the pilot tunnel is controlled at more than 3m. Advance support and temporary support during hole construction. The advance support adopts small conduits or large pipe sheds supplemented by advanced grouting re...

Embodiment 2

[0094] When the underground station has three or four floors underground, the anti-floating water level is relatively high, and it is not economical to simply increase the thickness of the floor or increase the rise-span ratio. The anti-floating problem can be solved by setting uplift piles in the middle of the floor. Such as Figure 10 shown.

Embodiment 3

[0096] For poor ground such as soft soil or loose sand layer, advance grouting reinforcement is performed on the surrounding ground of the pilot tunnel during the construction process to improve the excavation stability of the pilot tunnel and the foundation bearing capacity and deformation resistance of the arch foot. Such as Figure 11 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com