Design method and making process of fibre-optical grating sensitization strain transducer

A strain sensor and fiber grating technology, applied in the field of fiber grating increase and decrease sensitive strain sensor, embedded fiber grating increase and decrease sensitive strain sensor, can solve the problem of no increase or decrease sensitivity effect and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

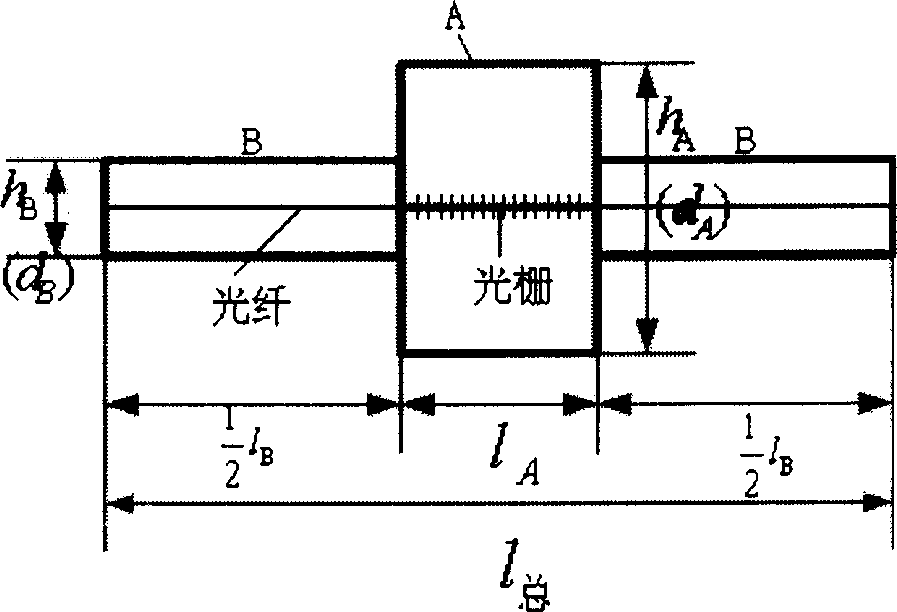

[0031] For specific engineering applications, the following two types of fiber grating increase and decrease sensitive strain sensors are designed:

[0032] (1) For surface strain monitoring of civil engineering, adhesive fiber grating increase and decrease sensitive strain sensors are required:

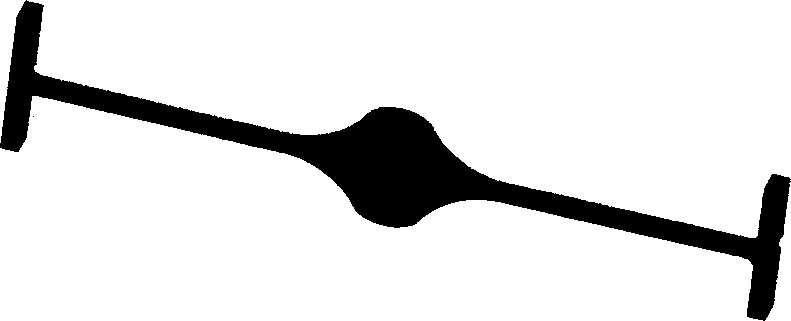

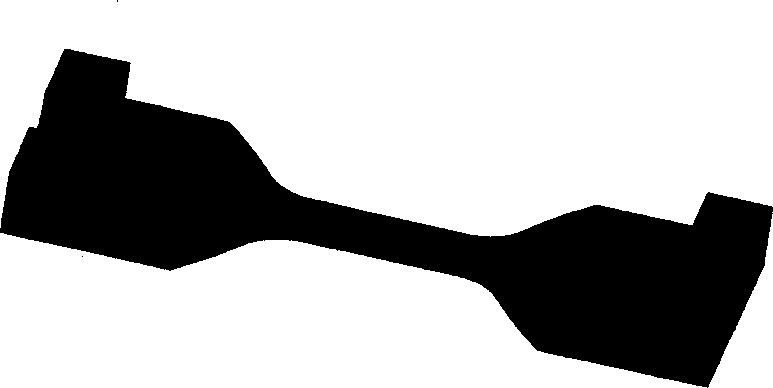

[0033] designed to be attached figure 2 , attached image 3 The flakes shown have the same thickness, then formula (3-6) becomes

[0034] K = K l + h A h B k L + 1 = K l + K h K ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com