Hydrogen storage tank mounting bracket structure for hydrogen energy aircraft

A technology for installing brackets and hydrogen storage tanks, which is applied in the field of aircraft, can solve the problems of not considering the extrusion collision problem, the decrease of aircraft stability, and the rearward center of gravity of the aircraft, so as to meet the requirements of light weight, small body mass, and reduce impact load Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

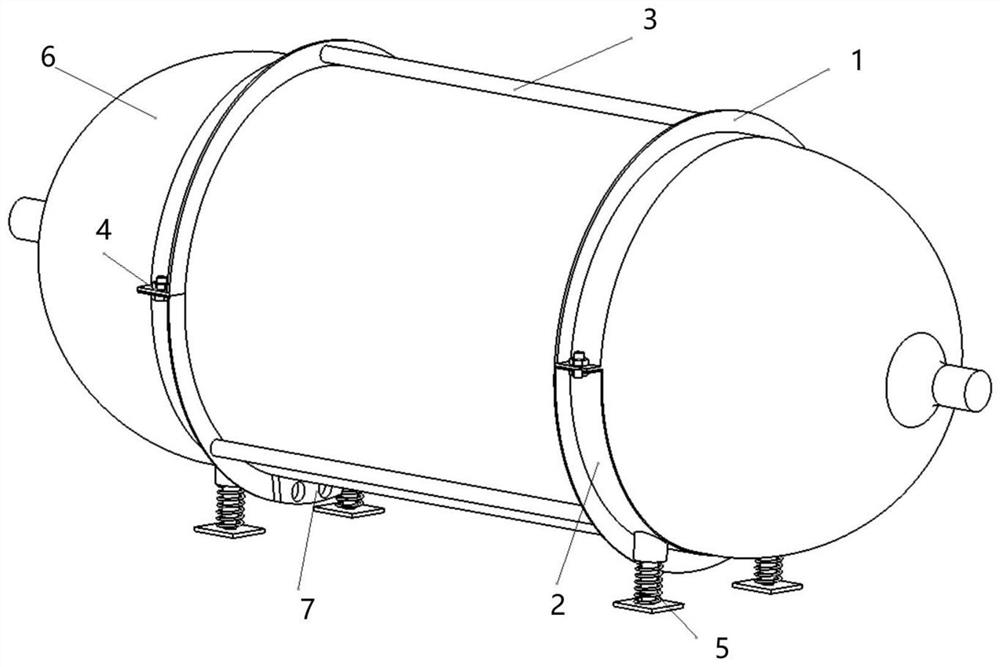

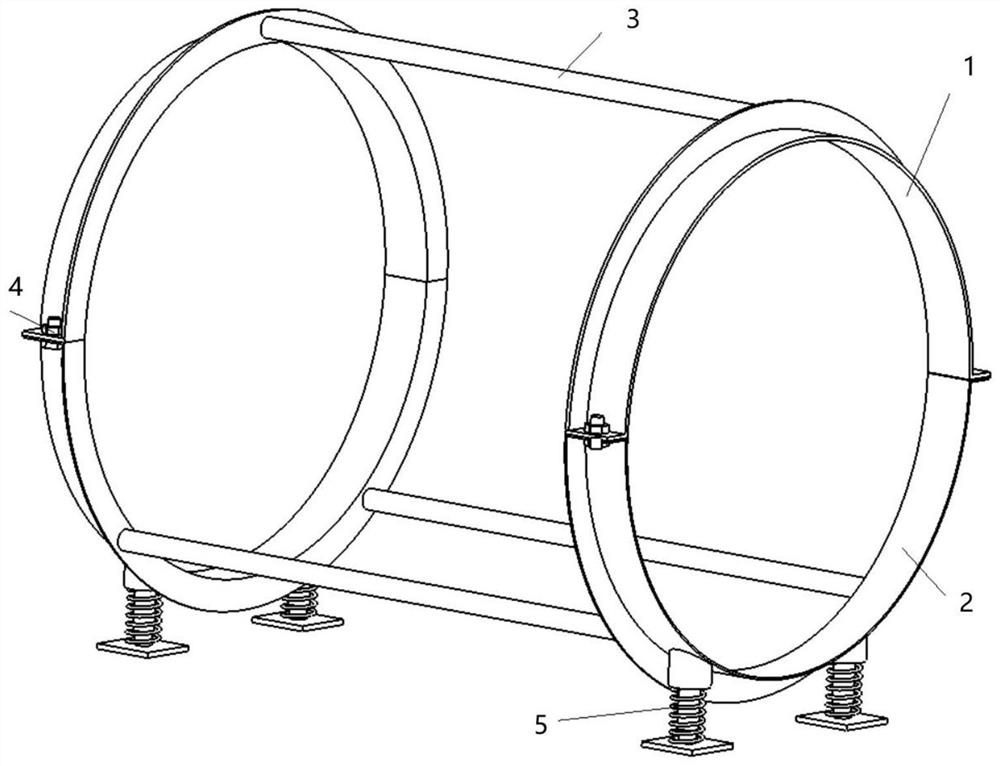

[0039] A hydrogen storage tank mounting bracket structure for hydrogen energy aircraft, such as figure 1 and figure 2 As shown, it includes two supporting bodies arranged at intervals, three connecting rods are arranged between the two supporting bodies, and the two ends of the three connecting rods are vertically fixed to the two adjacent supporting bodies respectively.

[0040] Among them, the three connecting rods have the same specifications, because the connecting rods participate in less load, so the strength requirements for the connecting rods are not high, and the three connecting rods can be connected by thin-walled steel pipes, and the triangle formed by the three connecting rods is stable. The structure greatly strengthens the structural stability of the mounting bracket when it bears the impact load when the aircraft lands.

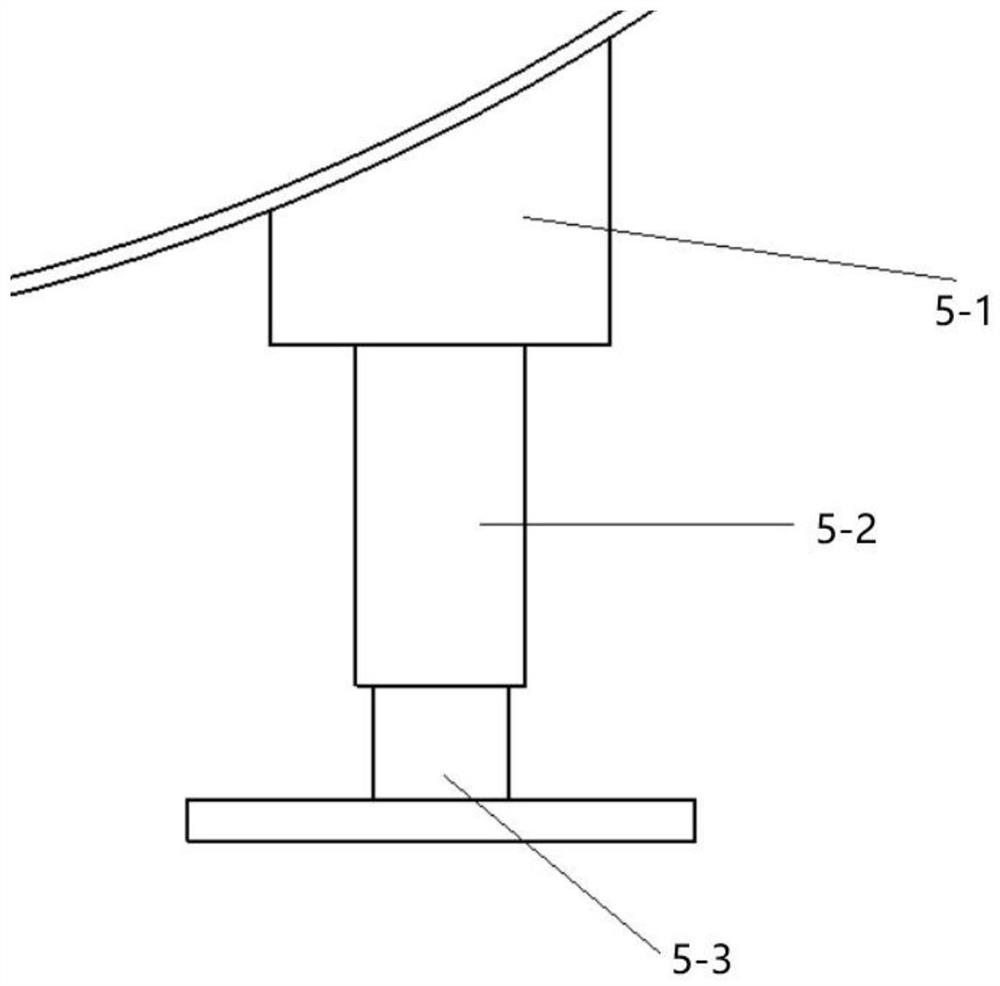

[0041] Among them, such as figure 1 , figure 2 and Image 6 As shown, the support body includes a first ring piece 1 and a second ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com