Waterweed scum removing ship

A technology for aquatic plants and scum, which is used in the cleaning of open water surfaces, ship accessories, water conservancy projects, etc., to achieve the effects of convenient operation, low production cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

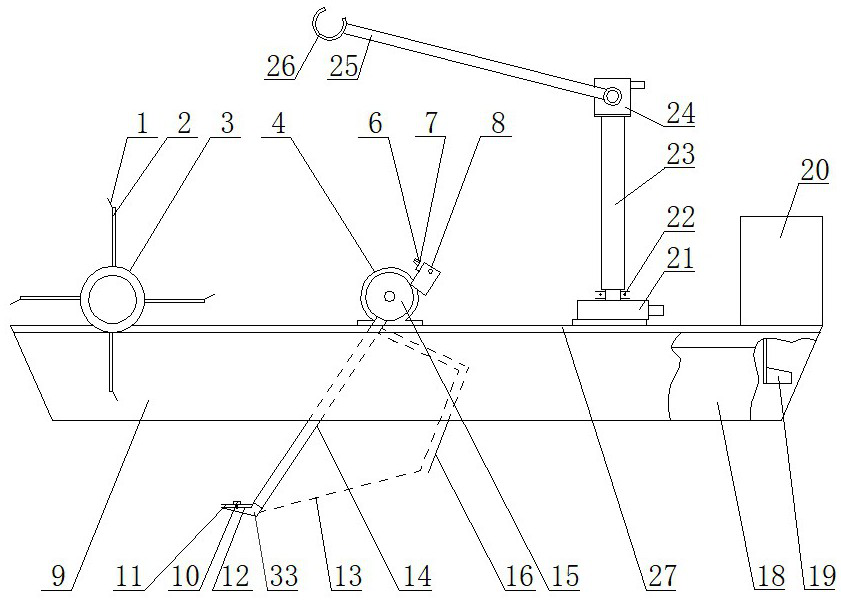

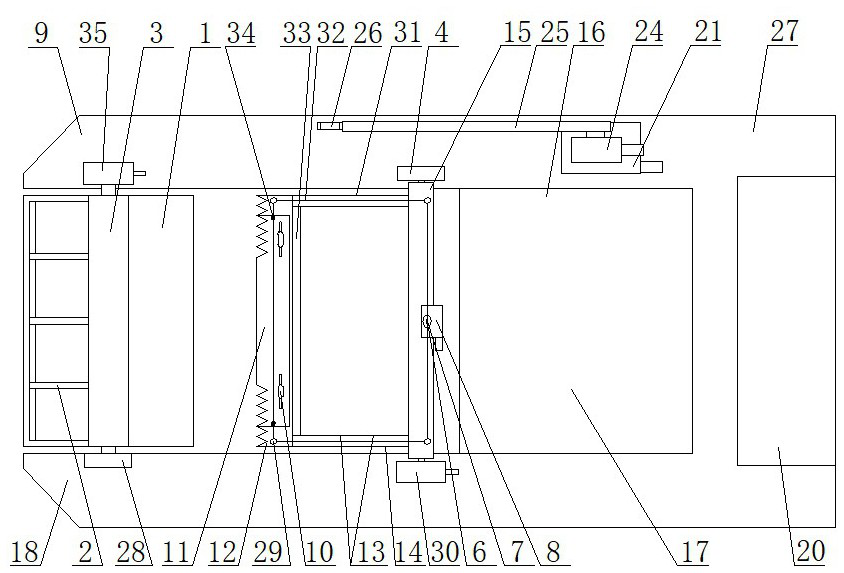

[0039] The present invention will be described in further detail below in conjunction with accompanying drawing

[0040] The waterweed scum removal ship is composed of the hull part, the hull driving device, the waterweed cutting and collecting device, the turret lifting device and the control room. 4. Bearing sleeve 6, eccentric shaft 7, rope motor reducer 8, right floating chamber 9, positioning slider 10, moving knife 11, fixed knife 12, slag collecting net 13, left turning arm 14, cutting machine shaft 15, Tension frame 16, aquatic plant scum stacking net 17, left floating chamber 18, rudder 19, control room 20, turret motor reducer 21, plane bearing 22, rotating tower 23, lifting motor reducer 24, lifting arm 25, crane Hook 26, hull frame 27, pump water roller bearing seat 28, pull cord guide wheel 29, cutting machine rotary arm motor reducer 30, cutting machine right rotary arm 31, pull rope 32, fixed knife rest 33, pull rope fixing card 34. Water pumping roller drive m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com