Liquid crystal display module assembly equipment

A liquid crystal display module and assembly equipment technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of high use and debugging cost, low economic benefit, complex structure, etc., and achieve the effect of rapid assembly and connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

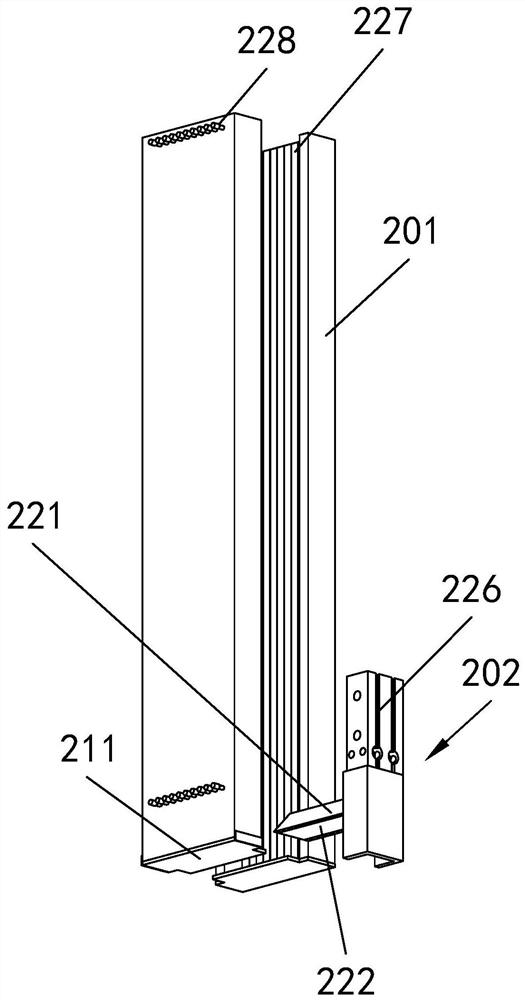

[0022] Example: see Figure 1-6 , a liquid crystal display module assembly equipment, including a support frame 100 and a PCB board crimping assembly 200, the support frame 100 is in the shape of a cube, and the PCB board crimping assembly 200 is installed in the support frame 100, which includes a tube shell 201 and abutment Pressing mechanism 202, the tube shell 201 is provided with a through groove along the vertical direction, the left and right ends of the through groove all pass through the tube shell 201, the upper and lower ends of the tube shell 201 are open, and the lower end of the tube shell 201 is connected to a For the limit plate 211 arranged horizontally, a torsion spring is sleeved on the rotating shaft, and the torsion spring acts on the limit plate 211 and makes it abut against the bottom surface of the tube shell 201. A pair of limit plates 211 are located on the tube shell 201 respectively. The front and rear sides of the front and back, and there is a gap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com