Solid cracking product heat energy solid-liquid exchange discharging device

A cracking product and discharge device technology, which is applied to household refrigeration equipment, products, educts, etc., can solve problems such as incomplete heat transfer, incomplete heat transfer of solid cracking products, and difficulty in processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

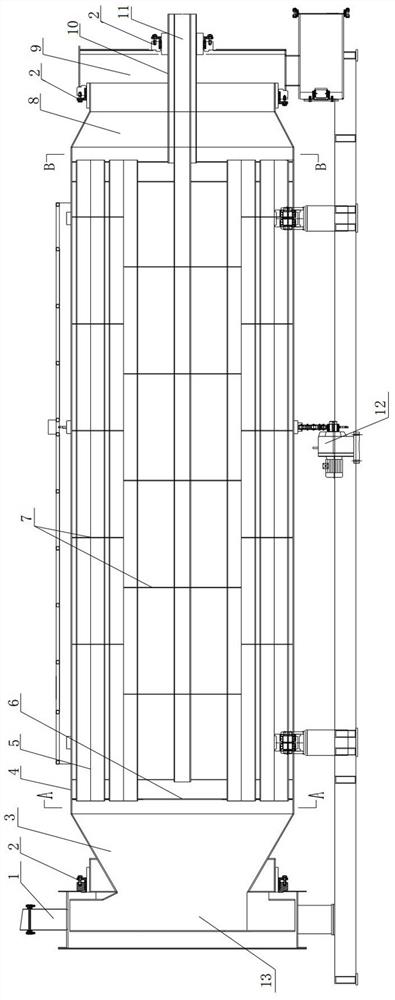

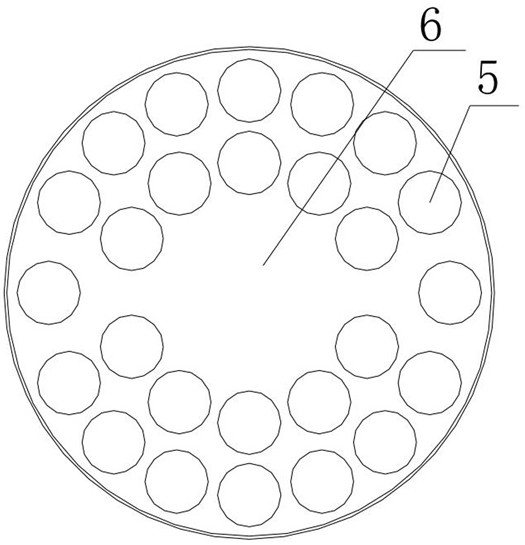

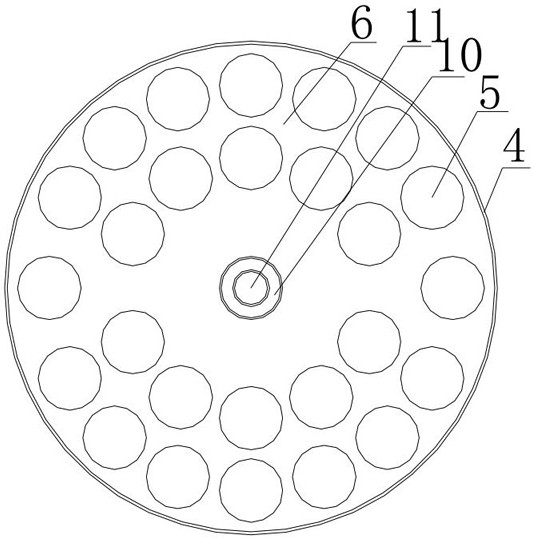

[0021] Such as figure 1 As shown, a thermal energy solid-liquid exchange discharge device for solid pyrolysis products includes a rotatable outer cylinder 4 and orifice plates 6 at both ends of the outer cylinder. One end of the outer cylinder 4 is connected to a The solid cracking product feed bin 13, the other end is connected to the solid cracking product outlet bin 9 through the second frustum transition section 8, and the center of the orifice plate located in the solid cracking product outlet bin 9 is provided with a water inlet pipe 10, which corresponds to The horizontal position of the outer cylinder body is a cavity, and the material tube 5 is uniformly arranged around the cavity, and the two ends of the material tube 5 are fixedly connected to the orifice plate 6, and a number of baffles 7 are arranged in the cavity, and the baffles 7 are adjacent to each other. The material pipe is fixedly connected, and the water inlet pipe 10 is also equipped with a return pipe 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com