A composite non-woven fabric cutting device

A non-woven, composite technology, applied in the field of cloth processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

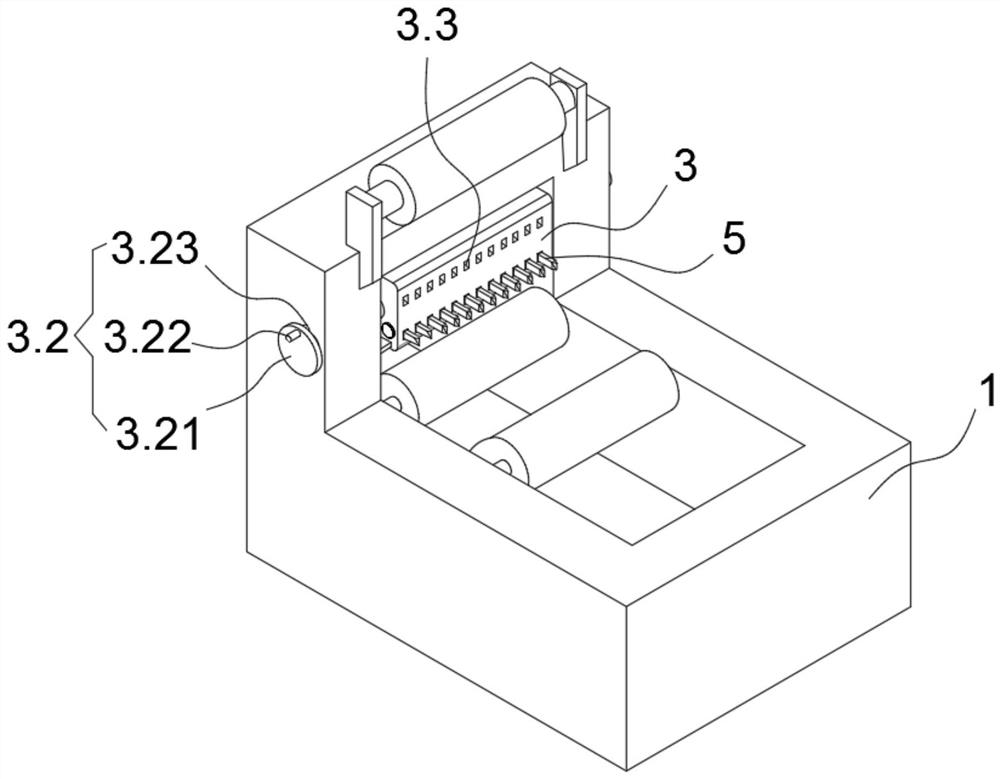

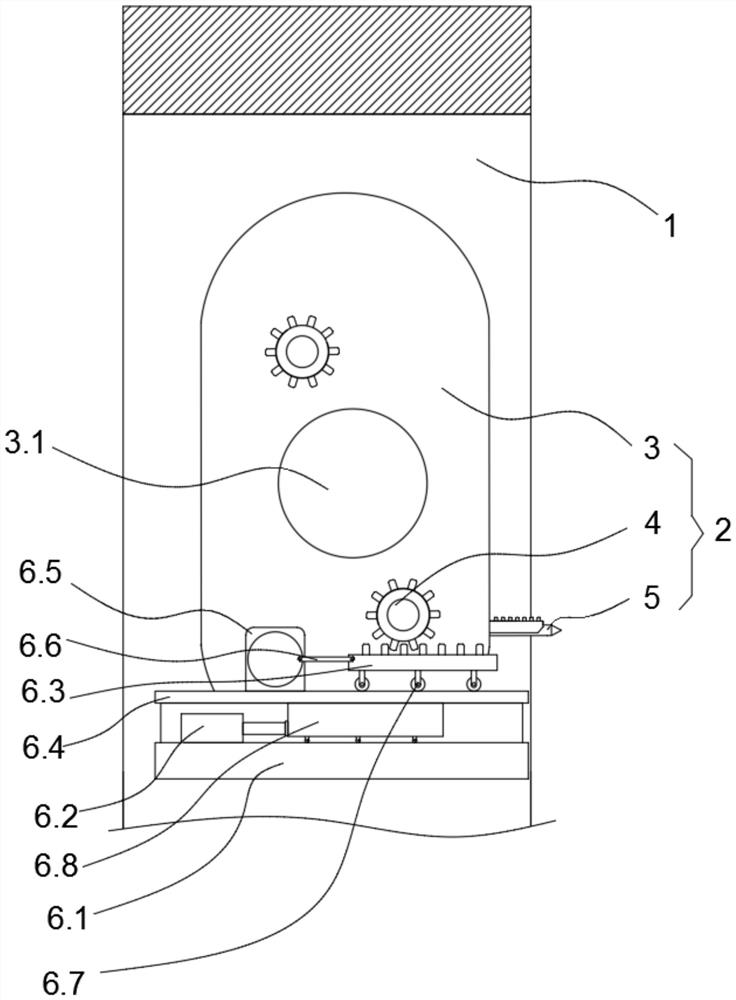

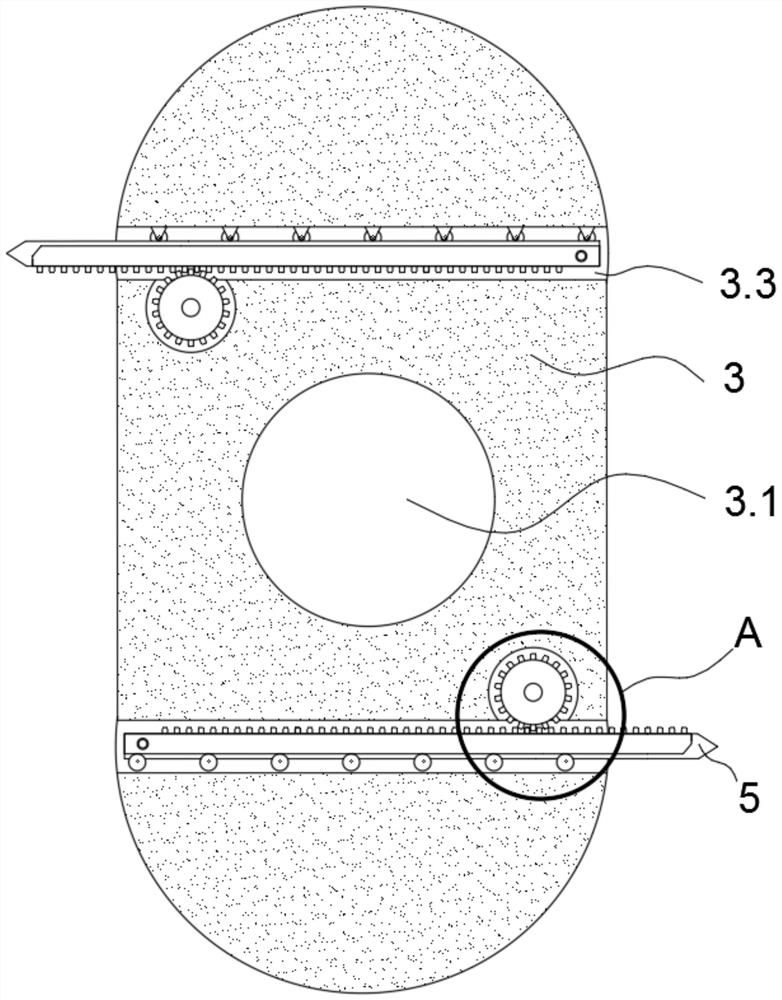

[0033] see Figure 1-7 , a composite non-woven fabric slitting device provided in the embodiment of the present invention comprises a base 1 on which a cutter mechanism 2 for cutting cloth is installed, and the cutter mechanism 2 includes:

[0034] Mounting beam 3, which is arranged on the base platform 1;

[0035] Drive assembly 6, which is arranged on the mounting beam 3;

[0036] A plurality of cutting knives 5, which are flexibly connected to the mounting beam 3;

[0037] The driving assembly 6 is used to drive the cutting knife 5 to move along the length direction of the knife body.

[0038] Concretely, the problem existing in the prior art is that the contact position of the cutting knife and the cloth is unique, generally the blade part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com