Sealing and supporting device for two ends of transition roller in sealing box

A technology of supporting device and transition roller, applied in glass manufacturing equipment, glass transportation equipment, manufacturing tools, etc., can solve the problems of affecting glass quality, inconvenient operation, heat loss, etc., to avoid the blocking of transition roller and reduce the trouble of installation , The effect of saving process and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

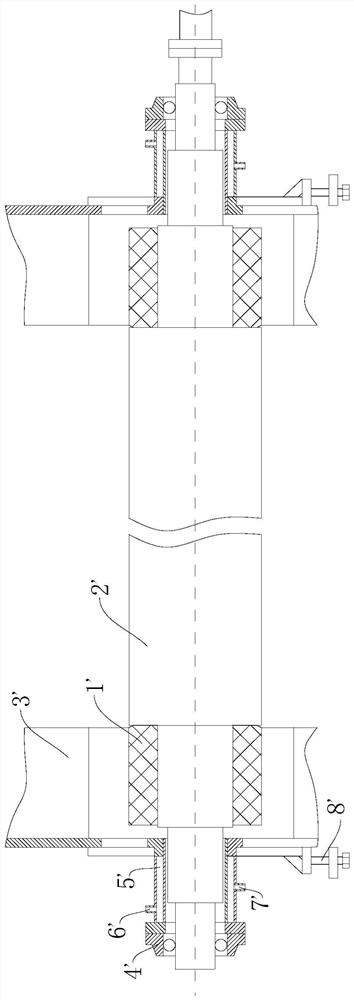

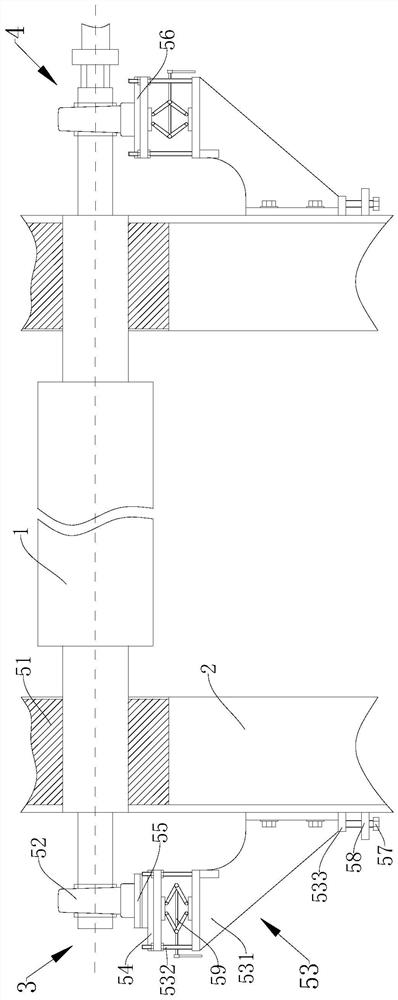

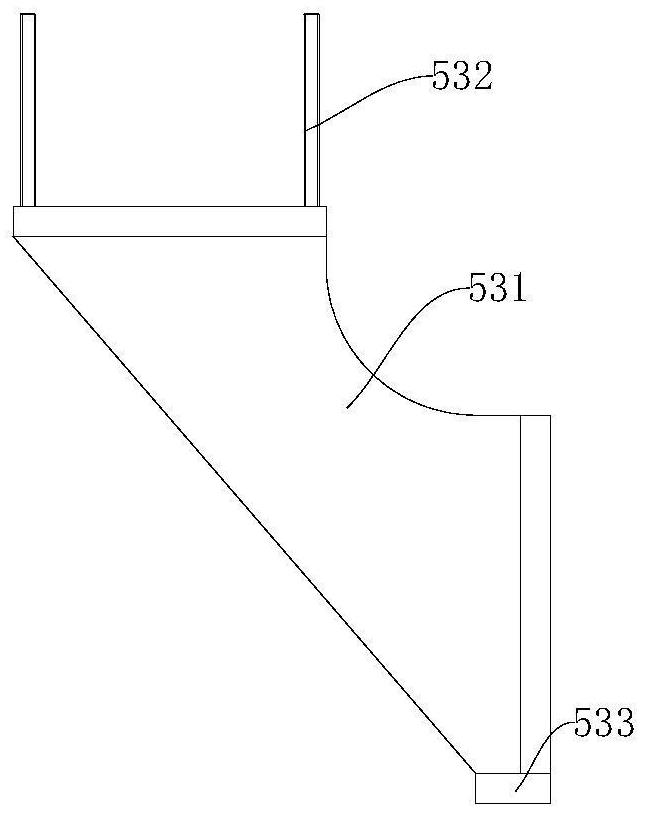

[0039] refer to figure 2 , the invention discloses a sealing and supporting device for both ends of a transition roller in a sealing box. The transition roller 1 runs through the sealing box 2. The two ends of the transition roller 1 are fixed to the shells on both sides of the sealing box 2. It is the moving end 3, and the other end is the fixed end 4; the sealing and supporting device 5 includes thermal insulation material 51, bearing housing 52, support 53, sliding seat 54, sliding plate 55, fixed plate 56, jacking wire 57, connecting plate 58 and elevator 59; inside the sealing box 2, the connection between the two ends of the transition roller 1 and the sealing box 2 is filled with elastic heat-insulating material 51; outside the sealing box 2, the two ends of the transition roller 1 are rotationally connected with the bearing seat 52; the transition roller 1 The bearing seat 52 of the moving end 3 is slidingly connected with the support 53, the bearing seat 52 of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com