Micro-power flotation separation equipment

A separation equipment and micro-power technology, applied in flotation water/sewage treatment, grease/oil/float removal device, sedimentation treatment, etc. problems, to achieve the effect of simple overall structure, improved air flotation efficiency, and increased air flotation treatment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to facilitate the understanding of the present invention, the present invention will be described more fully below with reference to the associated drawings. The present invention can be implemented in many different forms and is not limited to the embodiments described herein. Rather, these embodiments are provided so that the disclosure of the present invention will be thorough and complete.

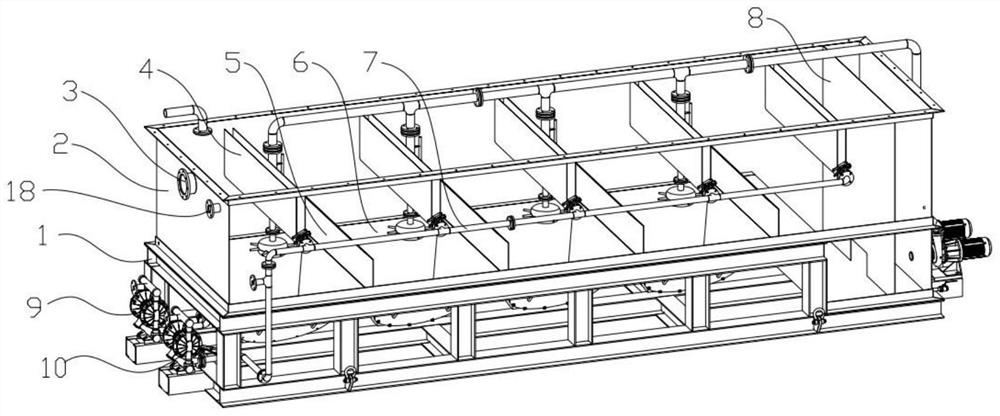

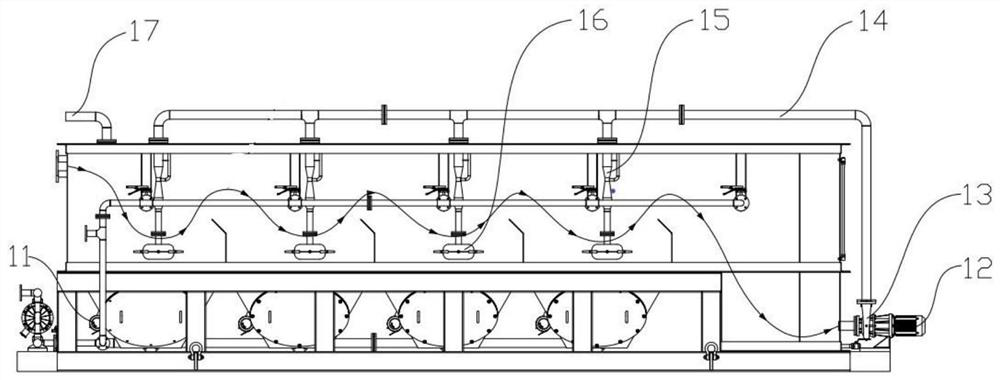

[0016] like Figure 1 to Figure 2 As shown, a micro-dynamic flotation separation equipment includes a support base 1, a box body 2, a mixed suspension liquid injection port 3, a U-shaped oil collection tank 4, a lower partition plate 5 of the box body, a slag collection bucket at the bottom 6, and an oil collection pipe Sink 7, box high partition 8, sludge diaphragm pump 9, oil diaphragm pump 10, sludge vibration motor 11, clean water centrifugal pump 12, circulating water centrifugal pump 13, circulating manifold 14, venturi tube 15, high efficiency Jet injector 16, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com