Two-gear reduction gear transmission mechanism matched with planetary speed reduction

A technology of transmission mechanism and reducer, which is applied in the direction of control devices, transportation and packaging, vehicle parts, etc., can solve the problems that the reducer cannot meet the switching between high and low gears, low transmission efficiency, and large motor load, so as to reduce load and increase The effect of improving the life of the motor and improving the transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

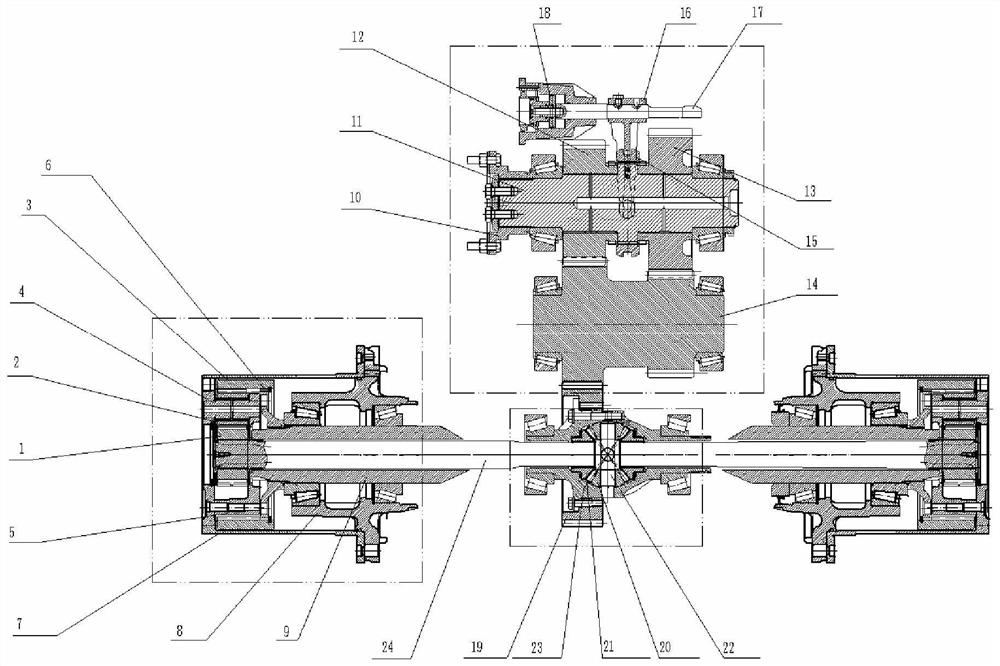

[0011] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0012] like figure 1 As shown, a two-speed reducer transmission mechanism matching planetary gear reduction in the present invention includes a wheel-side reducer, a bevel gear differential and a two-speed transmission. The two wheel reducers are coaxially installed with the bevel gear differential, and the two wheel reducers are respectively located at both ends of the bevel gear differential; the helical gear 19 in the bevel gear differential is connected to the gear in the two-speed transmission Shaft 14 engages.

[0013] The wheel reducer is a planetary reduction mechanism, and the planetary reduction mechanism includes sun gear 1, planetary gear 2, ring gear 3, pin shaft 4, planet carrier 5, ring gear bracket 6, bell hub 7, wheel hub 8 and sun gear shaft sleeve 9. Five planetary gears 2 mesh with the sun gear 1 and the ring ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com