Organic silicon slag exothermic and insulating riser sleeve and preparation method thereof

A thermal insulation riser sleeve and silicone technology, which is applied in the field of solid waste resource utilization, can solve the problems of restricting the popularization and application of heating risers, high price, and difficulty in the price of aluminum powder, and achieves longer solidification time, low cost, The effect of a short light-off time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

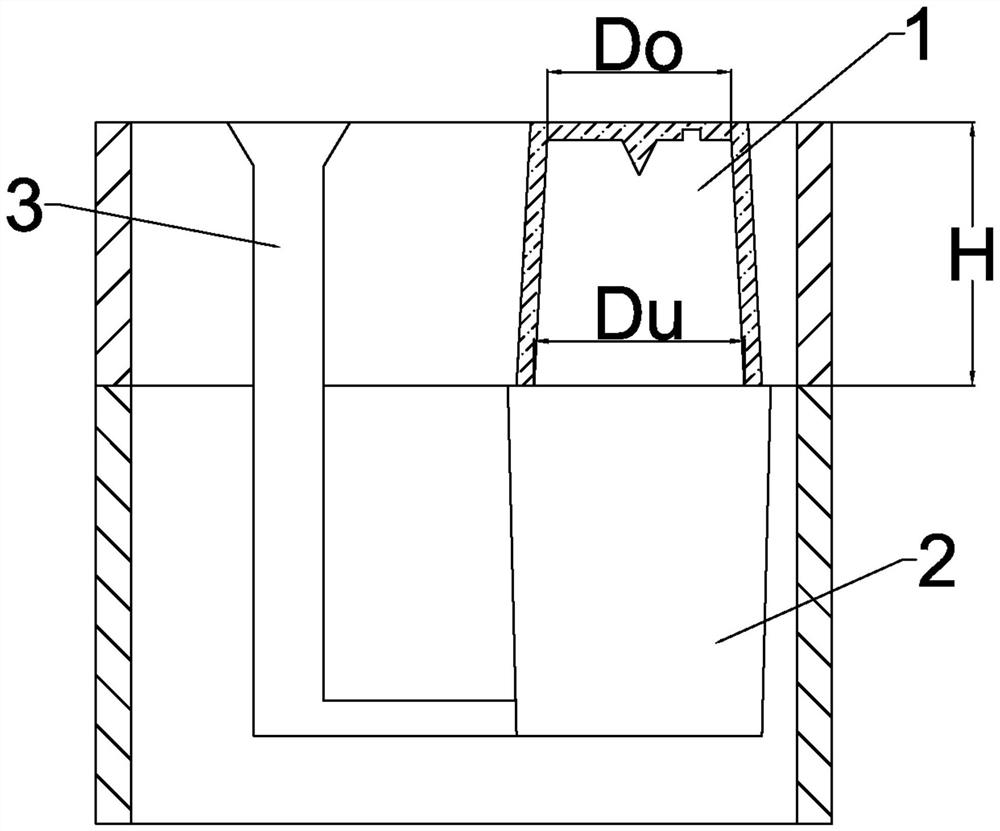

[0044] Based on the same inventive concept, the present application also provides a method of preparing the above-mentioned organic silicon slag fever heat insulation rings, including the following steps:

[0045] S1, organic silicon slag, oxidant, refractory aggregate, ingredient, flux, optionally aluminum powder, to obtain a mixture;

[0046] S2, adding an adhesive to the mixture and mixing a wet material;

[0047] S3, filled the wet material into the mold, and is suppressed as a rushing sleeve;

[0048] S4, after drying the riser, the silicone slag heat insulation riser.

[0049] In some embodiments, the organic silicon slag is mixed, and the organic silicon slag is also pretreated, and the pretreatment specifically includes: the silicone residue is washed with water, so that the pH is greater than 4, and then sieved after dehydration.

[0050] In some embodiments, the silicone residue is washed with water, removes the acid ions such as copper and the acidic substances such as ...

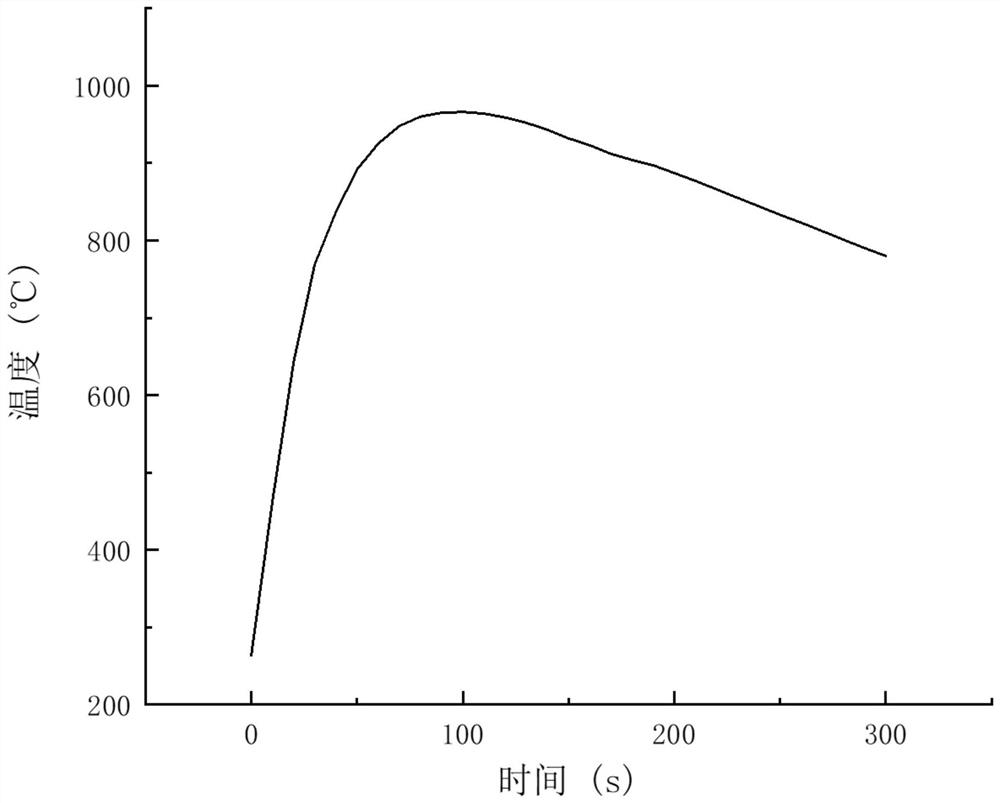

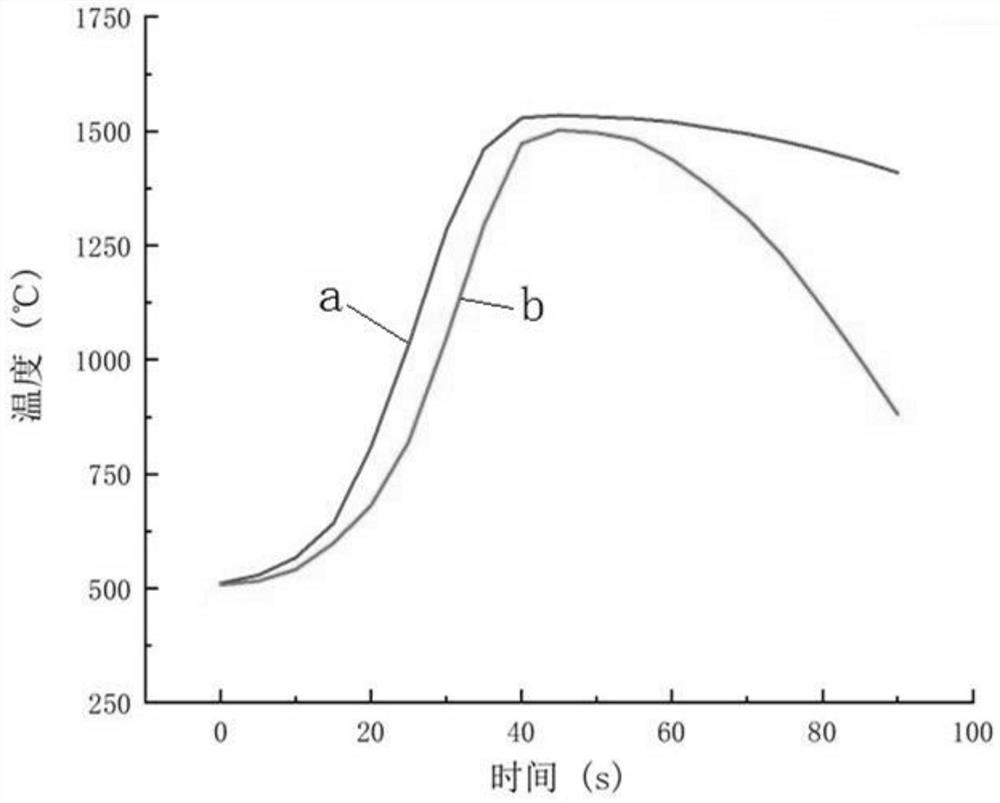

Embodiment 1

[0056] The present application provides a method for preparing an organic silicon-residual heat insulation riser, including the following steps:

[0057] S1, the silicone residue is washed with water, removes the acid ions such as copper and the acidic substances such as hydrochloric acid, so that the pH is greater than 4, the copper ion content is less than 0.5%, then dehydrated and dried under reduced pressure, then sieved to 100 ~ 200 mesh;

[0058] S2, taking 33 parts by weight of S1, the organic silicone slag, 17 parts by weight of the trihydrogen dioxide, 5 parts by weight of manganese dioxide, 33 parts by weight of the hollow boused bead, 7 parts by weight of potassium nitrate, 4 parts by weight After the potassium fluoroate is mixed and uniform, the mixture is obtained; wherein the mass fraction of 140 megadownload megadownload megadownload megadownload megadownload megadownload megadownload megadownload megadownload megadownload megadownload megadownload.

[0059] S3, tak...

Embodiment 2

[0063] The present application provides a method for preparing an organic silicon-residual heat insulation riser, including the following steps:

[0064] S1, the silicone residue is washed with water, removes the acid ions such as copper and the acidic substances such as hydrochloric acid, so that the pH is greater than 4, the copper ion content is less than 0.3%, then dehydrated and dried under reduced pressure, then sieved to 100 ~ 200 mesh;

[0065] S2, take 30 parts by weight of S1 obtained by organic silicone slag, 18 parts by weight of quadric oxide, 5 parts by weight of manganese dioxide, 30 parts by weight of hollow bounter, 6 parts by weight of sodium nitrate, 5 parts by weight After the potassium fluoroate is mixed and uniform, the mixture is obtained; wherein the mass fraction of 140 megadownload megadownload megadownload megadownload megadownload megadownload megadownload megadownload megadownload megadownload megadownload megadownload.

[0066] S3, take 9 parts by wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com