Flexible job shop multi-target scheduling method and system based on improved genetic algorithm

An improved genetic algorithm and flexible operation technology, applied in the field of flexible job shop multi-objective scheduling, can solve the problems of inaccurate solution results of flexible job shop scheduling optimization, not considering processing auxiliary time and resource constraints, and achieve true and accurate solution results. , solve the effect of accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

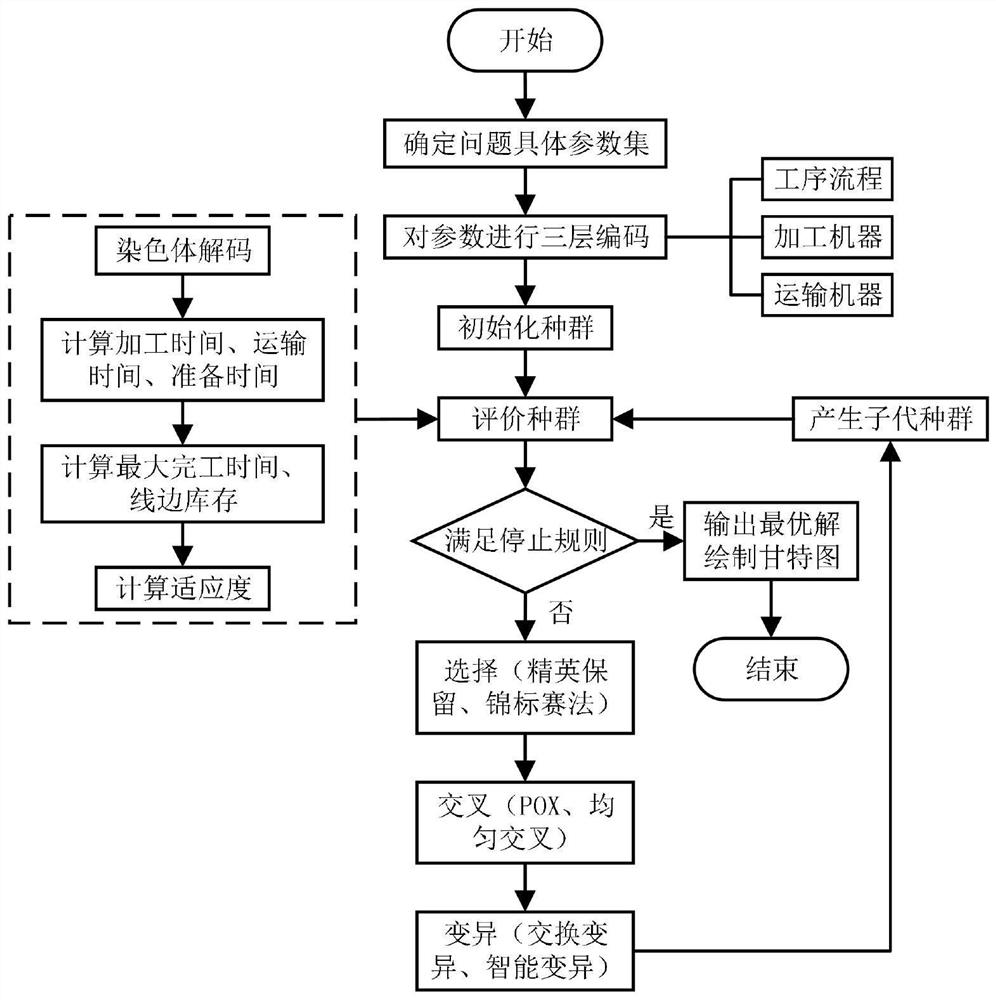

[0143] In the first aspect, the present invention firstly proposes a multi-objective scheduling method for a flexible job shop based on an improved genetic algorithm, the method comprising:

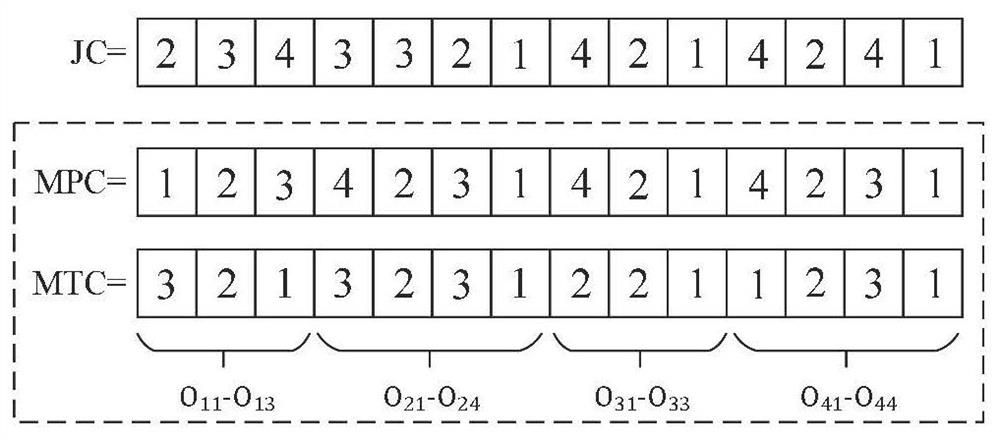

[0144] S1. Set the parameter set of the genetic algorithm; the parameter set includes: preset iterative algebra I, population size P, offspring mutation rate Pm, offspring crossover rate Pc, objective function weight α; total number of workpieces n; total number of processing equipment m , processing equipment number k, processing equipment Total number of transport machines a, transport machine number b, transport machine The total number of processes J for workpiece i i ;Process O i,j Available set of processing equipment Process O i,j Available set of transport machines

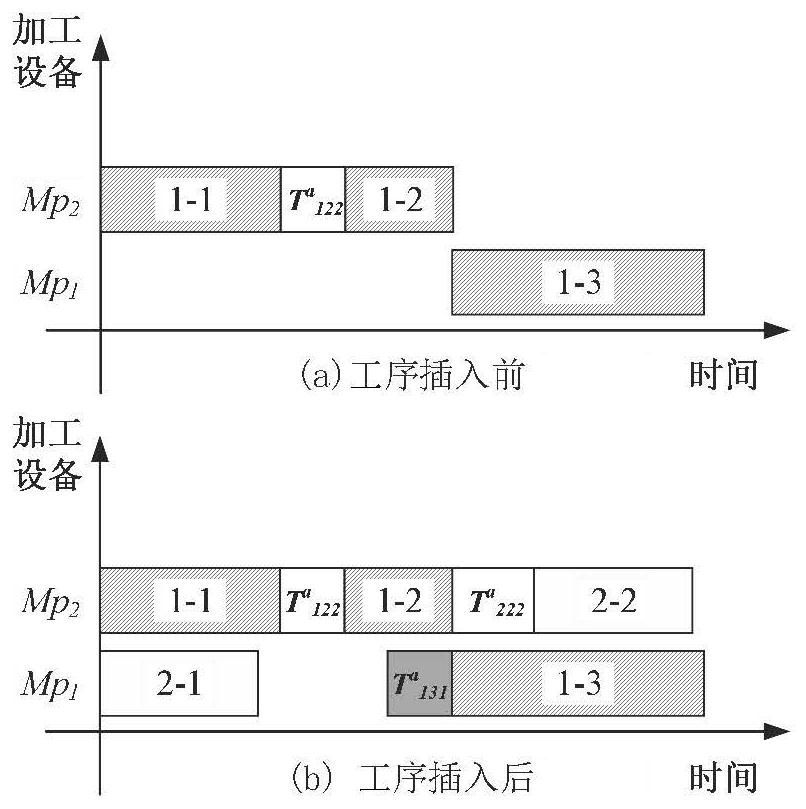

[0145] S2. Set the process part, processing equipment part and transportation machine part of the parameter set as the first substring, the second substring and the third substring of the chromosome respecti...

Embodiment 2

[0218] In the second aspect, the present invention also provides a flexible job shop multi-objective scheduling system based on an improved genetic algorithm, the system comprising:

[0219] A processing unit, the processing unit is used to perform the following steps:

[0220] S1. Set the parameter set of the genetic algorithm; the parameter set includes: preset iterative algebra I, population size P, offspring mutation rate Pm, offspring crossover rate Pc, objective function weight α; total number of workpieces n; total number of processing equipment m , processing equipment number k, processing equipment Total number of transport machines a, transport machine number b, transport machine The total number of processes J for workpiece i i ;Process O i,j Available set of processing equipment Process O i,j Available set of transport machines

[0221] S2. Set the process part, processing equipment part and transportation machine part of the parameter set as the first s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com