Conformal flexible mechanical sensing network and printing preparation method thereof

A conformal flexible mechanics and sensor network technology, applied in the field of flexible sensors, can solve problems such as insufficient fit, achieve accurate alignment placement, improve sensitivity, and solve the effects of nonlinear mechanical response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

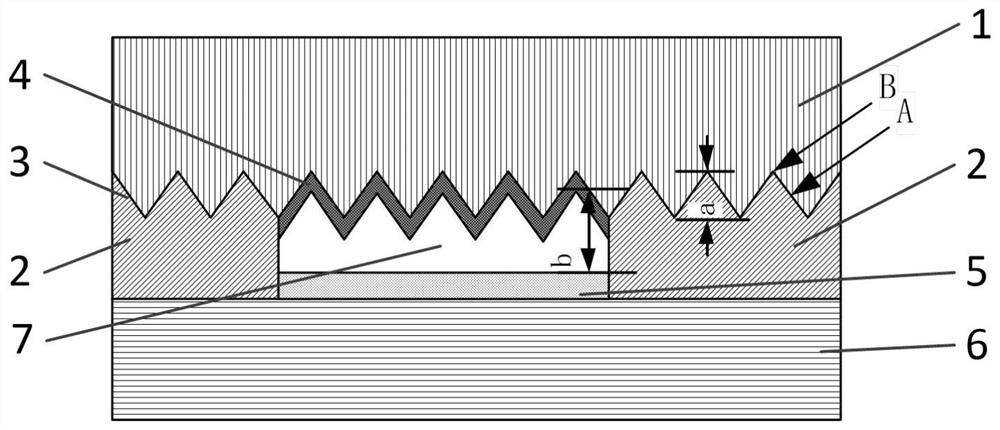

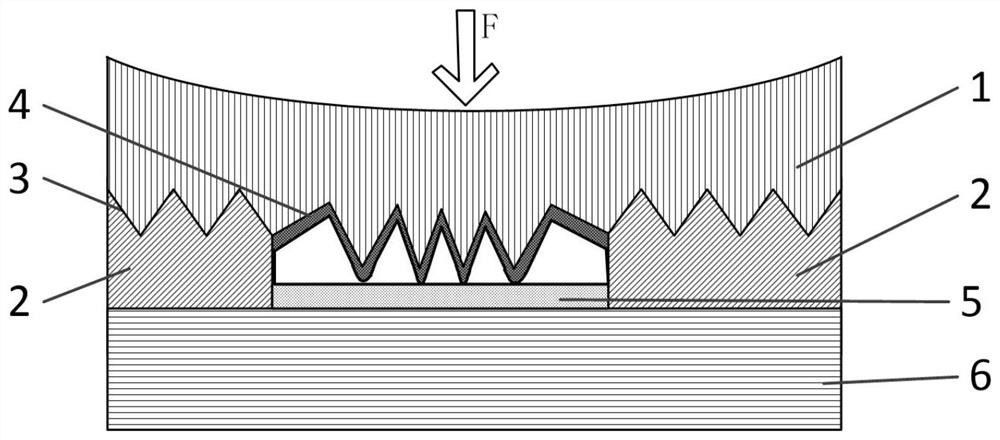

[0043] Such as figure 1 As shown, this embodiment provides a conformal flexible mechanical sensor network, including a flexible layer 1 and a conformal force-sensitive conductive layer 4;

[0044] The flexible layer 1 is composed of more than one segmented flexible layer; the shape of the segmented flexible layer is consistent with the shape of the segmented plane approximately expanded by the target curved surface; the conformal force-sensitive conductive layer 4 includes a force-sensitive sensing unit ; One side surface of the flexible layer 1 is the first surface; the conformal force-sensitive conductive layer 4 is provided on a partial area of the first surface.

[0045] The flexible layer 1 described in this embodiment can be a flexible material such as leather; the surface of the object to be measured on which the sensor network needs to be installed is the target curved surface. The target surface is approximately expanded into more than one split plane according to ...

Embodiment 2

[0055] Such as Figure 5 As shown, this embodiment provides a method for preparing a sensor network, including the following steps:

[0056] S1, expand the target surface into more than one split plane by the method of approximate expansion, which is denoted as the approximate expansion plane;

[0057] S2, cutting the flexible material according to the shape of the approximate unfolded plane to make a flexible layer; one side surface of the flexible layer is the first surface; the flexible layer includes more than one segmented flexible layer; the shape of the segmented flexible layer corresponds to The shape of the split plane is the same;

[0058] S3, according to the gradient screen printing process, a conformal force-sensitive conductive layer is printed on the first surface using a carbon nanomaterial conductive paste; the conformal force-sensitive conductive layer includes a force-sensitive sensing unit; the gradient screen refers to At the corresponding position of th...

Embodiment 3

[0069] This embodiment will briefly describe the preparation method of sensory web printing in combination with spheres.

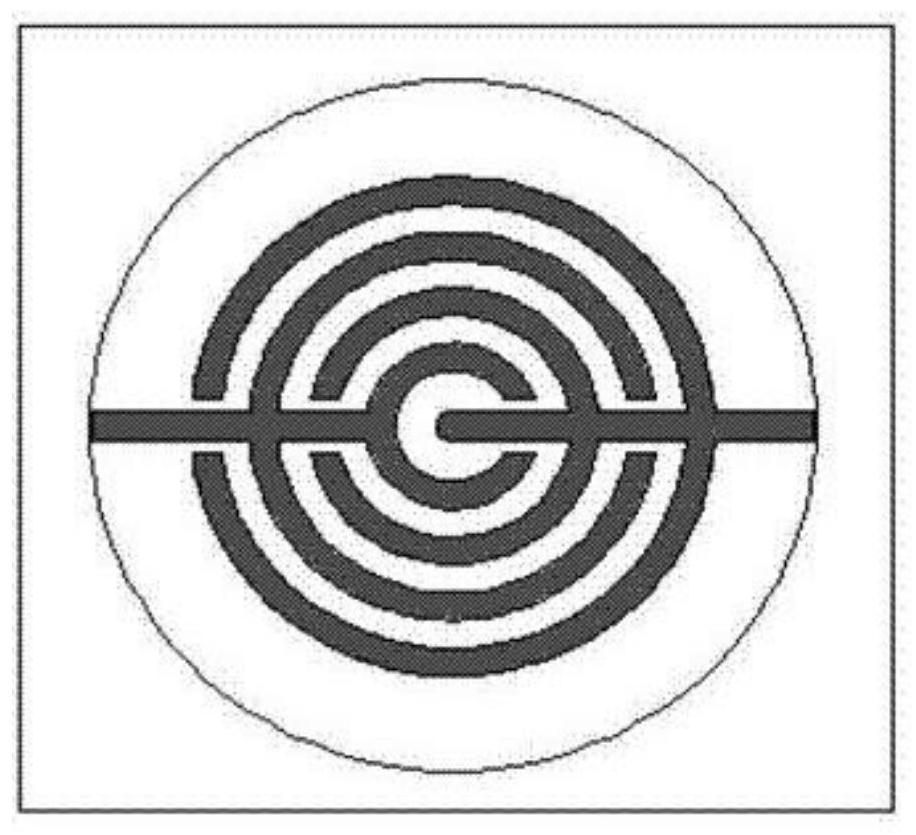

[0070] The approximate expansion of the sphere by the Gaussian curvature formula is as follows Figure 6 c) Multiple split planes of the shown pattern, all split planes are recorded as approximate unfolded planes;

[0071] Cutting the flexible material according to the approximate shape of the unfolded plane to make a flexible layer; one side surface of the flexible layer is the first surface;

[0072] according to Figure 7 As shown in , the segmented flexible layer of the sphere is laid out in the way that the extremes of the sphere are connected, and the force-sensitive sensing unit is printed on the first plane;

[0073] Prepare the base layer with ring-shaped interdigitated silver electrodes for printing; connect the ring-shaped interdigitated silver electrodes and the force-sensitive sensing unit through connecting wires; The base layer of the ann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com