A valve stem assembly, a main valve structure, and a pressure relief type two-position five-way electromagnetic reversing valve

A two-position, five-way, valve stem technology, applied in the field of reversing valves, can solve the problems of normally closed port opening, solenoid valve malfunction, etc., and achieve the effect of not easy to malfunction, high control safety factor, and good vibration and impact resistance performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

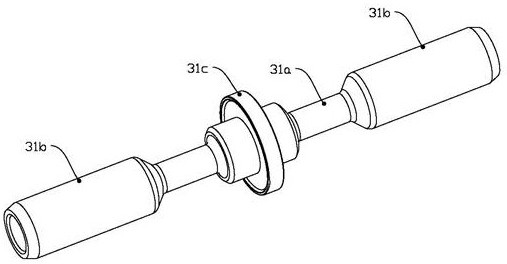

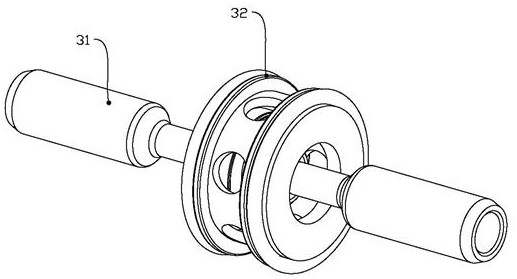

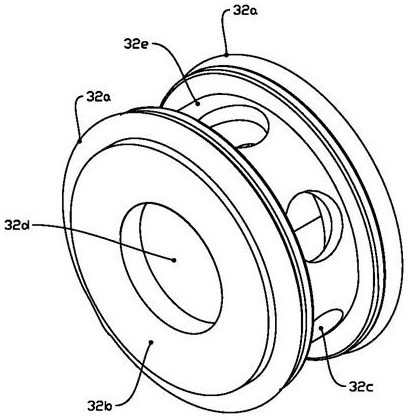

[0083] Such as Figure 1~3 As shown, a valve stem assembly is installed in the valve body 1 of the pressure relief type two-position five-way electromagnetic reversing valve, including:

[0084] The valve stem 31, the middle section 31a of the valve stem 31 protrudes outwards around the circumferential direction with an annular sealing cut-off structure 31c; the middle spacer 32 includes two rings of outer sealing structures 32a, two side sealing structures 32b, and two outer sealing structures 32b. The main body 32e connected with the other; the outer sealing structure 32a is sealed with the inner wall of the cavity of the valve body 1, and the first channel 32c for gas to enter the main body 32e is formed between the two outer sealing structures 32a, and the side sealing structure 32b is provided with a channel for gas to flow out. In the second passage 32d of the main body 32e, the sealing cut-off structure 31c blocks the second passage 32d on one side of the sealing struct...

Embodiment 2

[0101] Such as Figure 10~13 As shown, a main valve structure adopts the valve stem assembly 3 in Embodiment 1, including:

[0102] The valve body 1, and the combined structure composed of the rear cover piston assembly 2, the valve stem assembly 3 and the front cover piston assembly 4 connected in sequence; the rear cover piston assembly 2 forms a rear cover piston chamber 11 with one end of the cavity, and the front cover piston assembly 4 and the other end of the cavity form the front cover piston cavity 12, the combined structure moves along a straight line, and in the direction perpendicular to the linear movement, the extrusion area of the rear cover piston assembly 2 for the gas in the rear cover piston cavity 11 is larger than that of the front cover piston The extrusion area of the component 4 for the gas in the piston cavity 12 of the front cover, and the linear movement of the combined structure is performed due to the pressure difference generated by the gas on...

Embodiment 3

[0107] Such as Figure 16~18 As shown, a pressure relief type two-position five-way electromagnetic reversing valve includes the main valve structure in the second embodiment, and the pilot assembly 5; the valve body 1 is provided with an air inlet 13, a first working port 14, a second The working port 15, the pilot air intake channel 16 and the pilot air outlet channel 17, the gas entering from the air inlet 13 enters the front cover piston cavity 12 and the pilot piston cavity of the pilot assembly 5 through the pilot air intake channel 16 respectively, and the pilot assembly 5 is powered on When the power is off, the gas in the pilot piston chamber is introduced into the atmosphere, or, when the power is off, it is introduced into the rear cover piston chamber 11 through the pilot air outlet channel 17; the combined structure performs position switching during the linear motion to realize the air inlet 13 and the first working port. 14, or the communication between the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com