Flexible clamping structure of code wheel of reflecting photoelectric encoder

A photoelectric encoder, reflective technology, applied in the direction of instruments, measuring devices, conversion sensor output, etc., can solve the problems of poor temperature adaptability and vibration and shock resistance, poor economy of indium steel code disc seat, poor eccentricity stability of code disc, etc. , to achieve the effects of good temperature adaptability, good vibration and shock resistance, and small eccentric changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

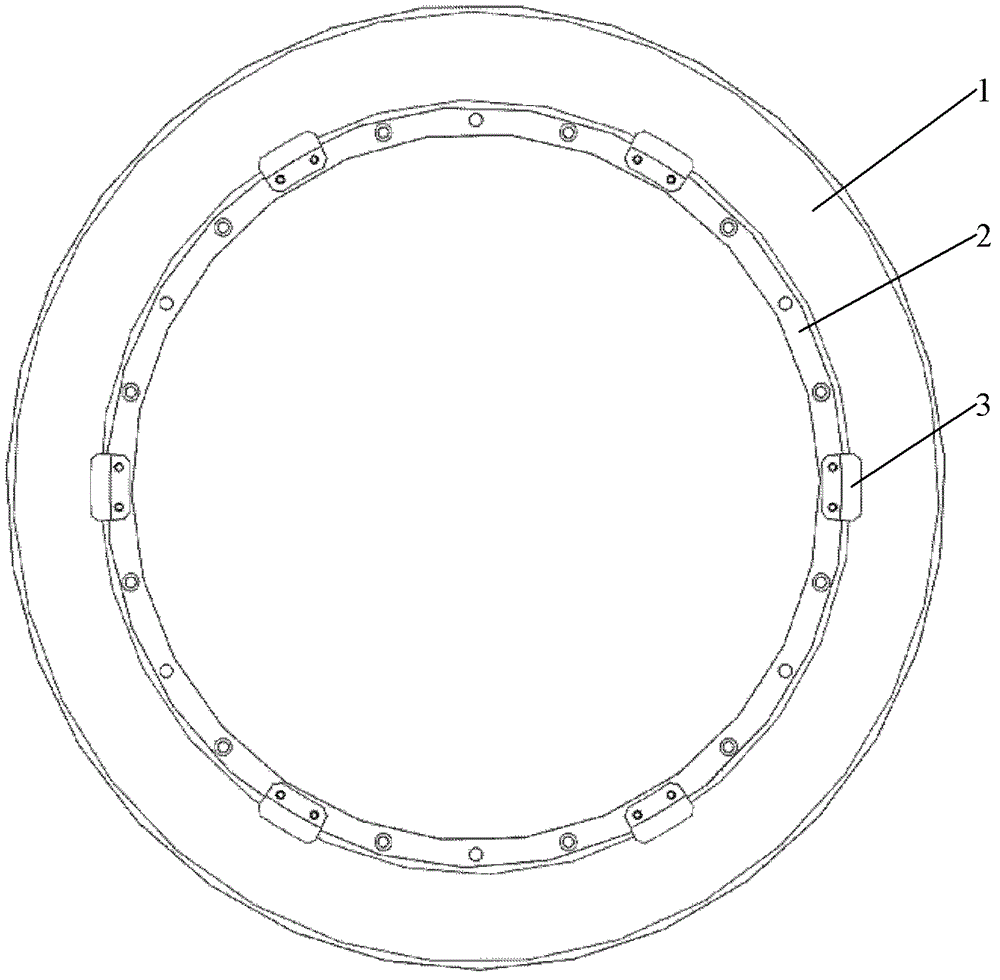

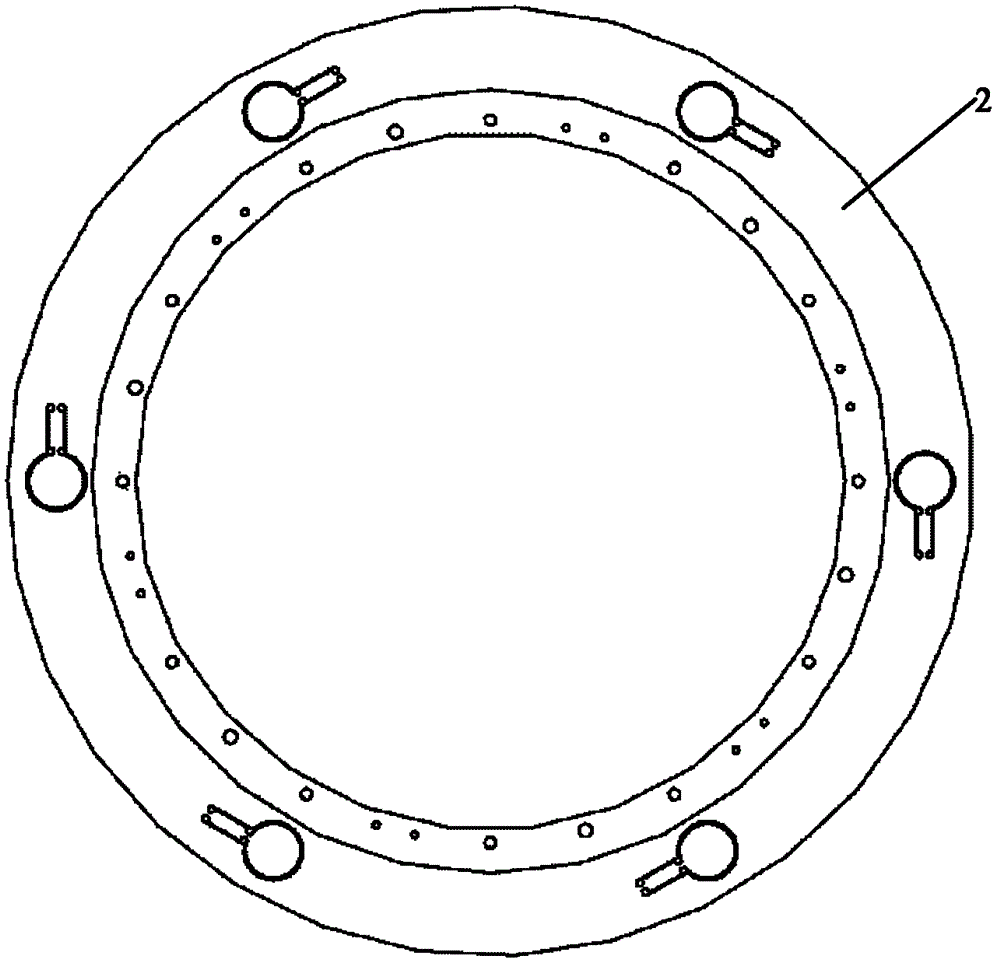

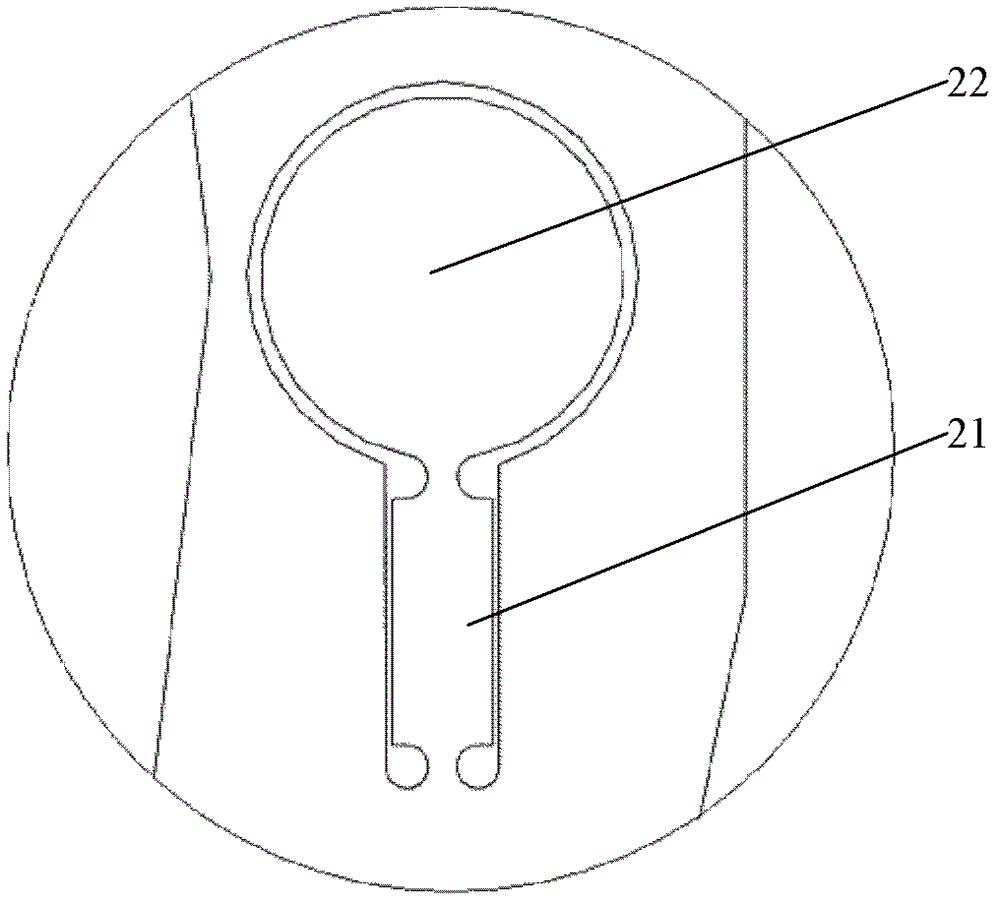

[0011] The flexible clamping structure of the code disc of the reflective photoelectric encoder according to the present invention figure 1 , figure 2 , image 3 , Figure 4 The implementation of the shown structure includes a code disc seat 2 and a stopper 3; a double flexible hinge rod 21 is provided on the code disc seat 2, and an adhesive disc 22 bonded to the code disc is provided at the suspended end of the double flexible hinge rod. The hinge rod 21 is evenly distributed along the circumference of the code disc bonding area on the code disc seat, at least 3; the stopper 3 is fixedly connected with the code disc seat 2 by screws, and the stopper 3 is evenly distributed along the inner circumference of the code disc seat, and is connected with the code disc seat. Leave a small gap between the plates.

[0012] The code disc seat is made of the same material as the rotating shaft, generally 40Cr, and the double flexible hinge rod 21 and the adhesive disc 22 are integral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com