Full-specification box leather error prevention detection system and method

A detection system and error prevention technology, applied in the field of the tobacco industry, can solve the problems of the box skin being unable to meet the demand, unsuitable for on-site use, cumbersome operation, etc., and achieve the effect of optimizing the interactive interface, saving space, and saving modification costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

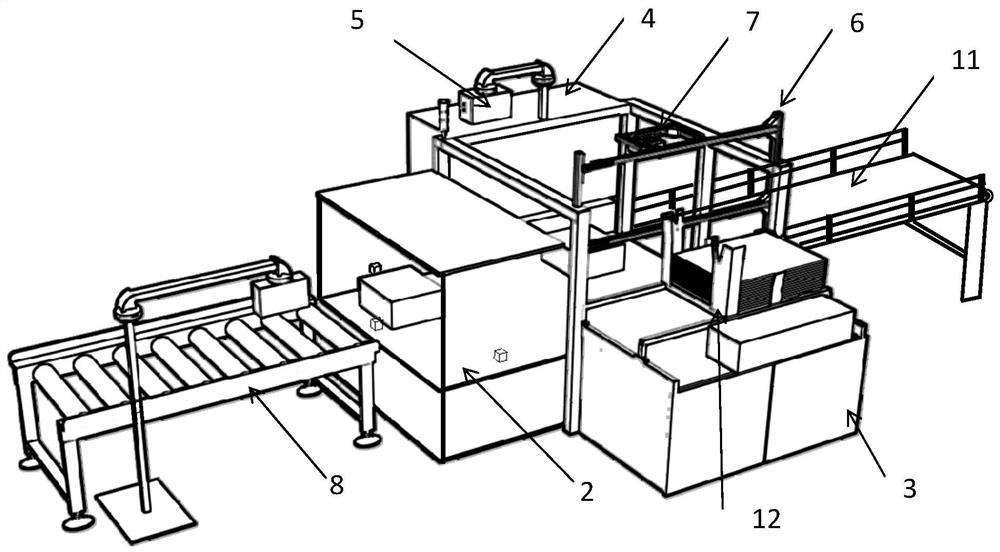

[0054] refer to Figure 1~2 , a full-scale box leather error-proof detection system, including

[0055] Packing machine and code scanning device 7;

[0056] The box packing machine is a YP11 type box packing machine, which includes a feeding and discharging device, a tape sealing device 2, an electric control cabinet 3 and an industrial computer 4.

[0057] The feeding and discharging device includes the rod cigarette feed passage 11 and the sealing discharge passage 8 arranged on the left and right sides of the case packing machine, wherein the rod cigarette feed passage 11 is a belt conveying passage, and the sealing discharge passage 8 is a roller Shaft transmission channels are used to transport cigarettes and packaged cigarette boxes respectively; the feeding and discharging device also includes a carton feeding turntable 12 arranged above the electric control cabinet 3, which is used for conveying cartons to be packaged, and cartons are fed into A number of cases are r...

Embodiment 2

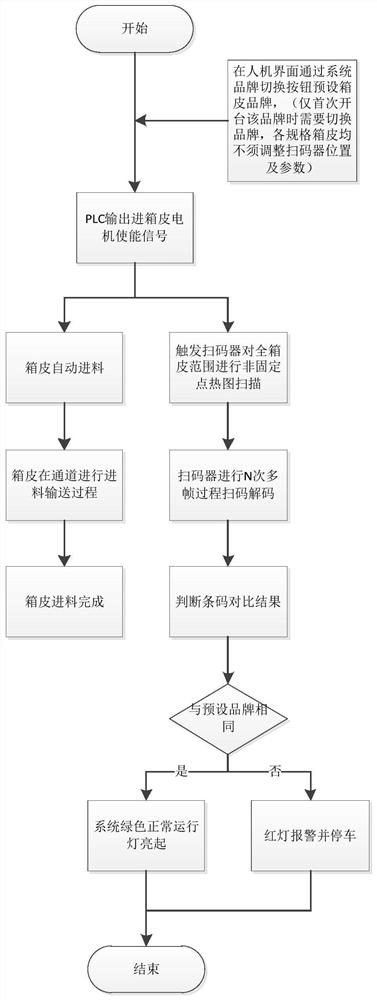

[0062] This embodiment is a kind of full specification box skin anti-error detection method, refer to image 3 , which includes:

[0063] S1, equipment installation

[0064] Fix the code scanning device 7 at an appropriate height above the box packer through the detection bracket 6;

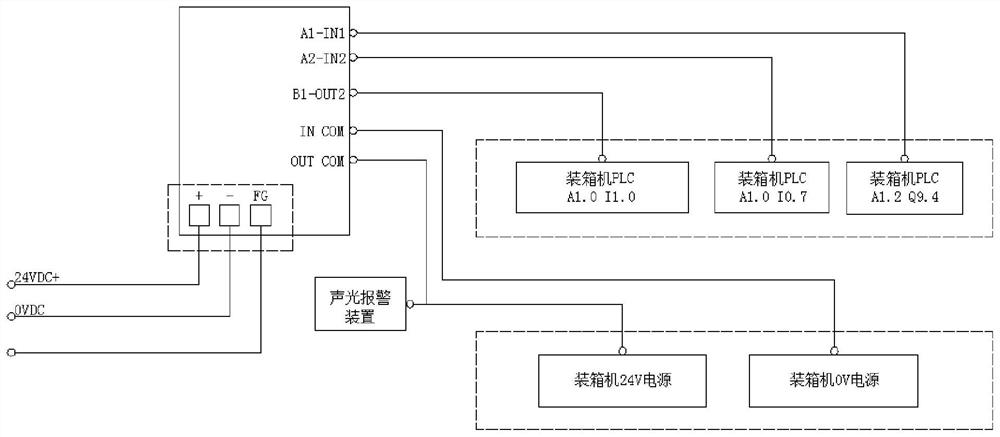

[0065] S2, line connection

[0066] Each functional port of the code scanning device 7 is communicatively connected with the industrial computer 4 and the electric control cabinet 3, and connected to a power supply;

[0067] S3, device debugging

[0068] Perform function debugging and height adjustment, focus correction, and image acquisition time interval (200ms) setting of each function port of the code scanning device 7, and control the input of the code scanning device 7 and receive its output signal through the industrial computer 4PLC controller, where IN1 input The terminal is used to trigger the dynamic multi-frame decoding signal in a single cycle, the IN2 input terminal is used to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com