Material receiving device of numerical control lathe

A material receiving device, CNC lathe technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing and other directions, can solve the problems of increasing production processes and human resources, affecting production safety, scratching workers, etc., to reduce The effect of production process and human resources, security and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] use Figure 1-Figure 7 A material receiving device of a numerically controlled lathe according to an embodiment of the present invention is described as follows.

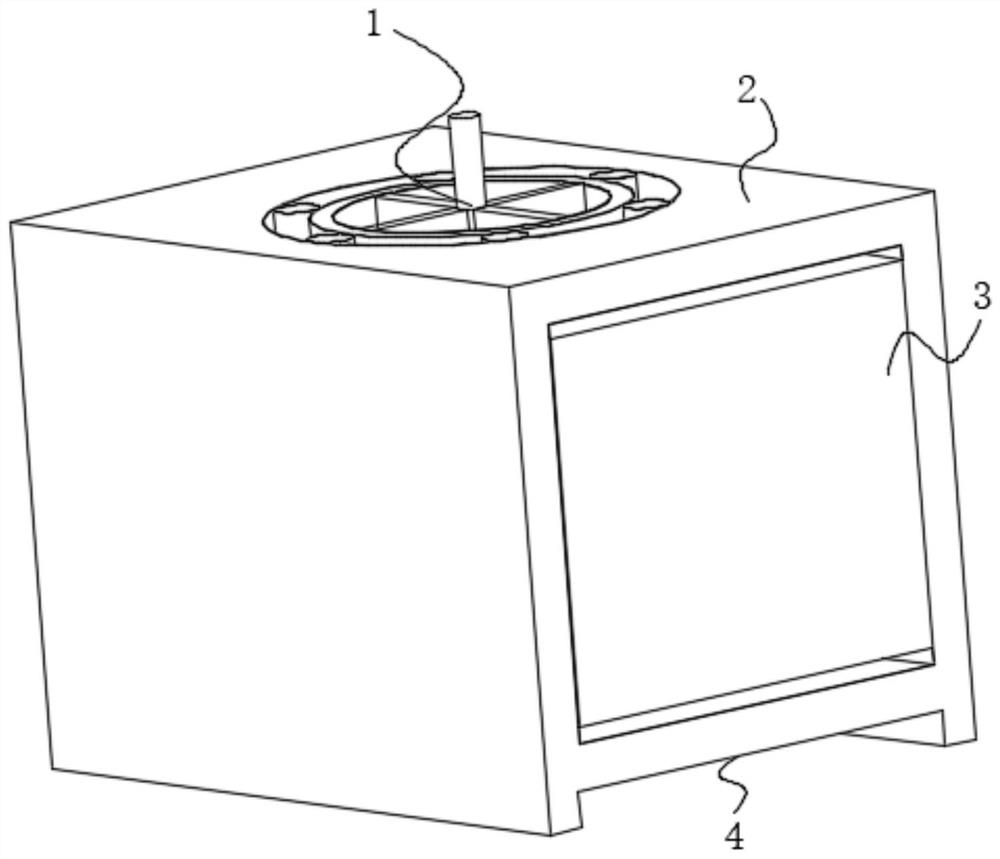

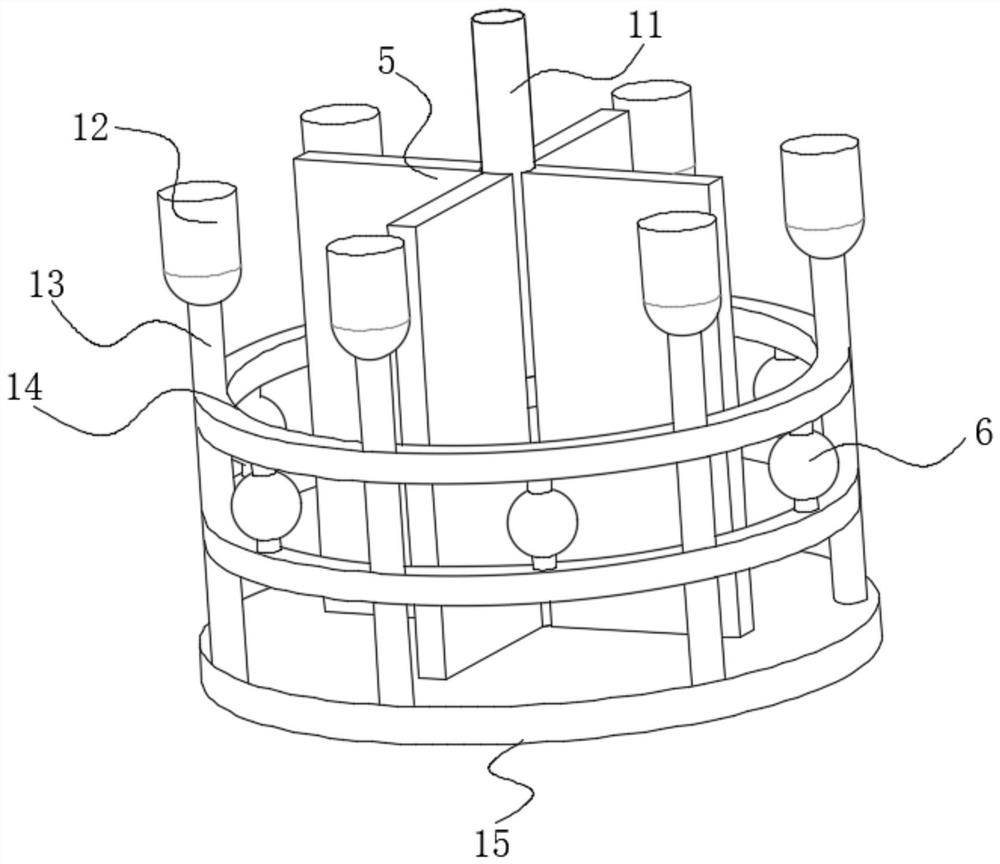

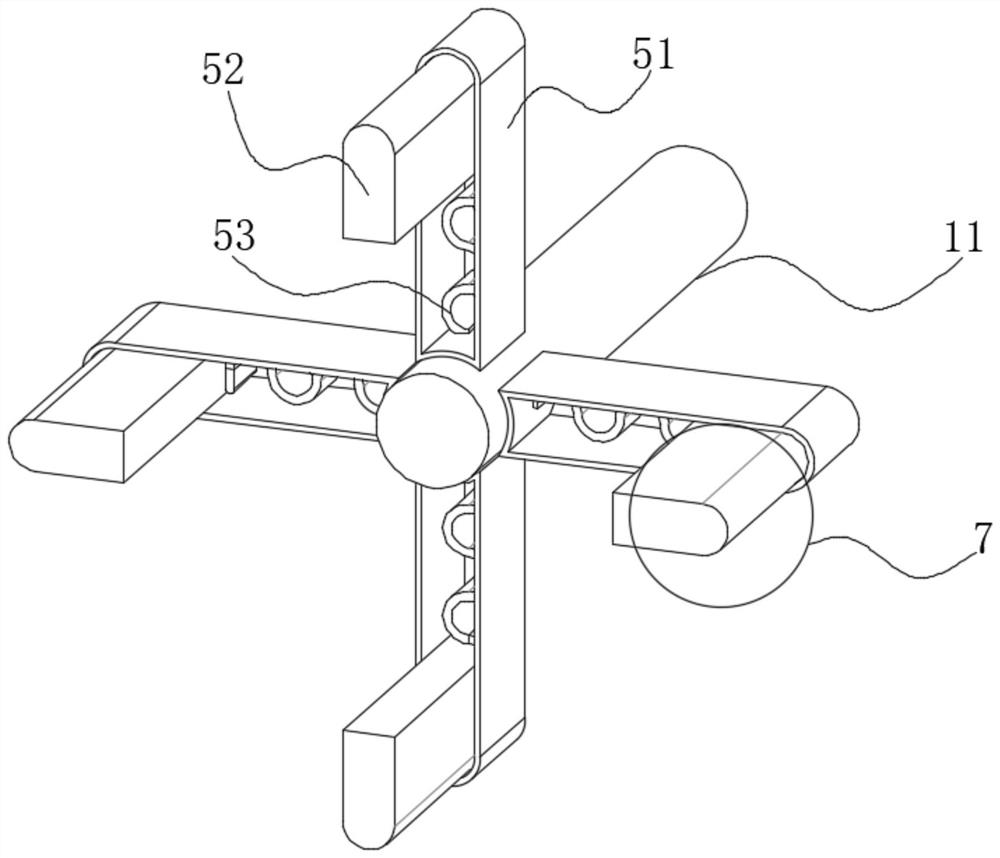

[0024] Such as Figure 1-Figure 7 As shown, a material receiving device of a numerically controlled lathe according to the present invention includes a box body 2, the top of the box body 2 is provided with an inlet, and the top of the box body 2 is connected with a rotating shaft through the inlet. Drum 1, the outer surface of the drum 1 is slidingly connected to the inner wall of the box body 2, both sides of the box body 2 are fixedly connected with baffles 3, and the bottom end of the box body 2 is fixedly connected with an opening plate 4 , the outer surface of the opening plate 4 is fixedly connected to the bottom end of the inner wall of the box body 2. Before the device works, the top of the rotating cylinder 1 is connected to the power source of the machine tool, so that the rotating cylinder 1 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com