Stamping die for skylight mounting bracket

A technology for installing brackets and stamping dies, applied in the field of stamping dies, can solve the problems of complex structure of stamping equipment, low installation accuracy of skylights, and reduced production efficiency, and achieve the effects of improving installation accuracy and assembly performance, simple structure, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

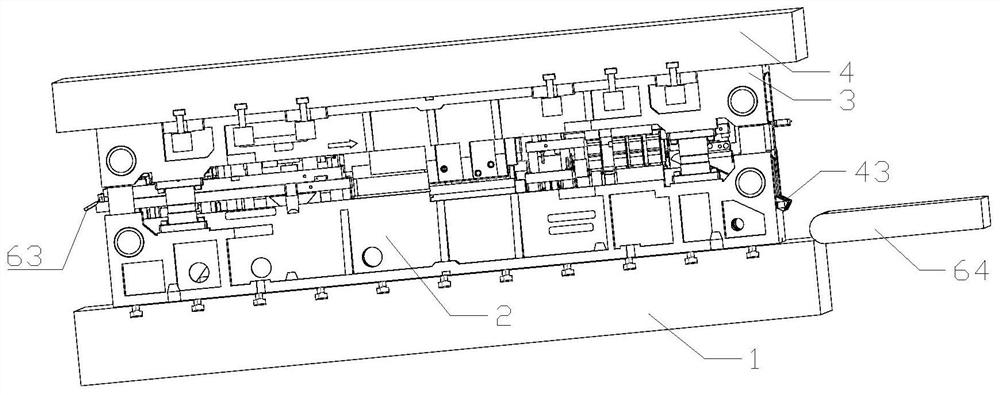

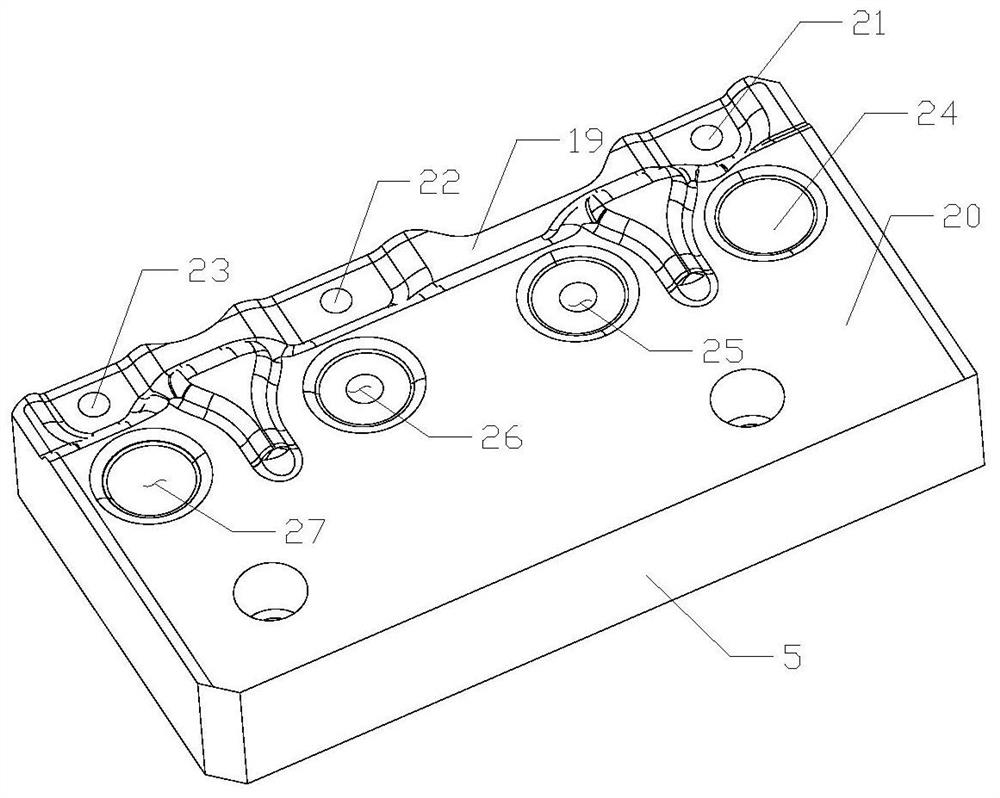

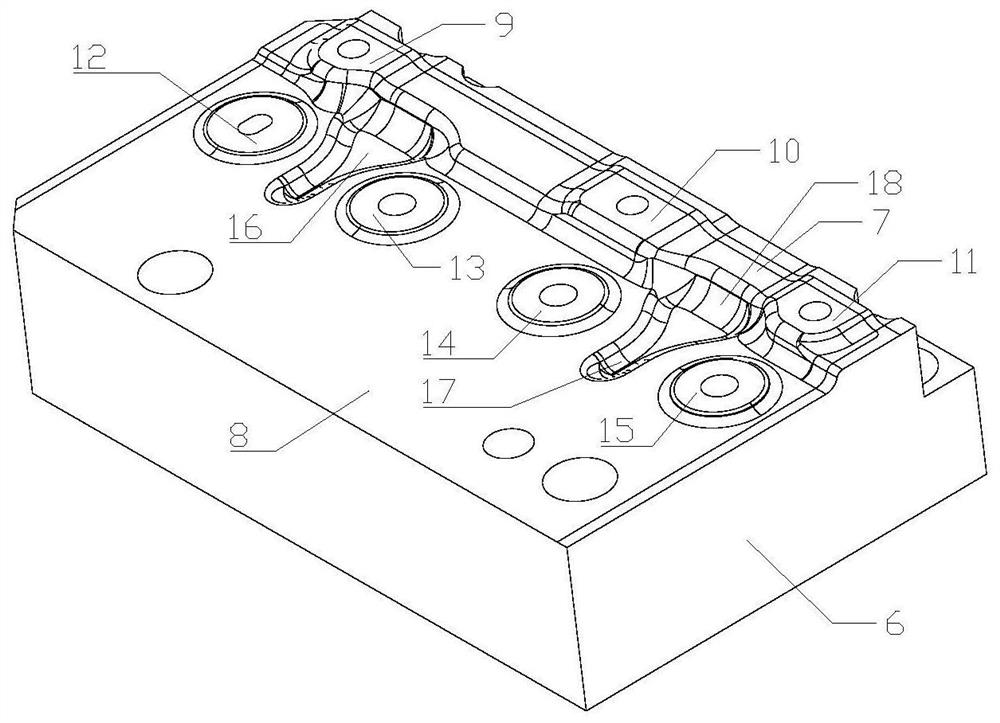

[0039]The present invention provides a stamping die for a skylight mounting bracket, comprising a lower mold base 1, a lower mold body 2 is provided on the lower mold base 1, an upper mold body 3 is arranged above the lower mold body 2, The upper mold body 3 is arranged on the upper mold base 4, a material cutting device is provided between the upper mold body 3 and the lower mold body 2, and a forming device is provided at the rear of the material cutting device, and the forming device A punching device is provided at the rear of the slab; the cutting device cuts off excess material on the sheet, and the forming device shapes the sheet, and punches the sheet after forming to form a skylight mounting bracket. In the present invention, a pair of The mold is stamped multiple times, which improves the production efficiency of the mounting bracket, makes the product quality higher, and has a simple structure and low operation difficulty, which further improves the production effici...

Embodiment 2

[0046] This embodiment provides a mounting bracket for a sunroof, including a bracket protrusion 44, one side of the bracket protrusion 44 is provided with a bracket plane part 45, and one side of the bracket plane part 45 is provided with a bracket Bending portion 46, an angle is set between the bracket bending portion 46 and the bracket plane portion 45; the bracket raised portion 44 is provided with a first bracket protrusion 47, a second bracket protrusion 48, a third bracket Protrusion 49; the bracket plane part 45 is provided with a fourth bracket protrusion 50, a fifth bracket protrusion 51, a sixth bracket protrusion 52, and a seventh bracket protrusion 53, and the fourth bracket protrusion 50, A first bracket groove 53 is provided between the fifth bracket protrusions 51, a second bracket groove 55 is provided between the sixth bracket protrusion 52 and the seventh bracket protrusion 53, and the second bracket protrusion 48. A third bracket groove 56 is provided betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com