Preparation method of cyanea nozakii kishinouye extract

The technology of extract and jellyfish, which is applied in the field of preparation of jellyfish extract, can solve problems such as the development of unseen deep-processed products, and achieve the effect of lowering blood pressure and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: a kind of preparation method of jellyfish extract comprises the following steps:

[0037] (1) Take the washed white jellyfish tentacles, homogenize the tissue, and freeze-dry to obtain freeze-dried powder;

[0038] (2) Mix freeze-dried powder, calcium dihydrogen carbonate, sodium bicarbonate, microcrystalline cellulose and water, stir, and disperse evenly to obtain a dispersion; freeze-dried powder, calcium dihydrogen carbonate, sodium bicarbonate, microcrystalline cellulose The input mass ratio of water and water is 1:0.02:0.04:0.02:10;

[0039] (3) Enzymolysis:

[0040] ① Adjust the pH of the dispersion to 7.8, raise the temperature to 45°C, add trypsin, stir to make it enzymolyze, the enzymolysis time is 2.0hr, after enzymolysis, raise the temperature to 100°C and keep it warm for 15min to inactivate the enzyme; the dispersion and trypsin The mass ratio of protease is 100:0.5;

[0041] ②Adjust the pH of the dispersion to 7.0, raise the temperature to...

Embodiment 2

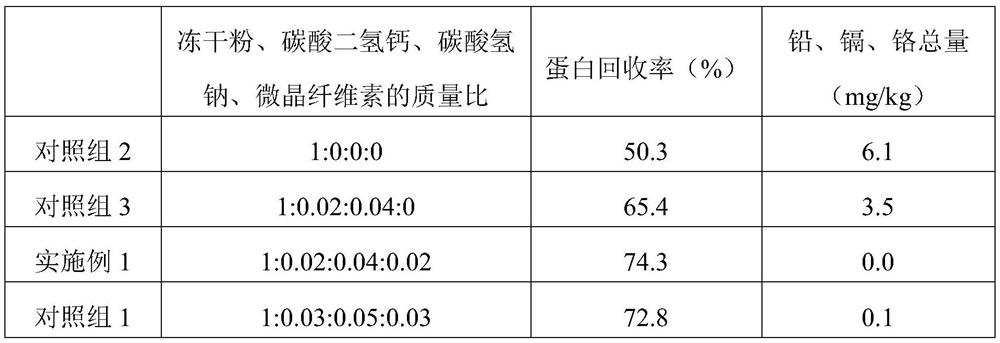

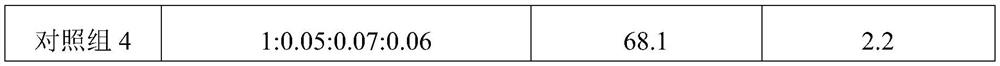

[0046] Embodiment 2: the influence of step (2) on the preparation method of jellyfish extract

[0047] Test object: embodiment 1, control group 1-4.

[0048] Control group 1: with reference to Example 1, the difference from Example 1 is that in step (2), the input mass ratio of freeze-dried powder, calcium dihydrogen carbonate, sodium bicarbonate, microcrystalline cellulose and water is 1:0.03 :0.05:0.03:10.

[0049] Control group 2: with reference to Example 1, the difference from Example 1 is that calcium dihydrogen carbonate, sodium bicarbonate or microcrystalline cellulose are not added in the freeze-dried powder in step (2), only water is added and the freeze-dried powder and The input mass ratio of water is 1:10.

[0050] Control group 3: with reference to Example 1, the difference with Example 1 is that microcrystalline cellulose is not added in the freeze-dried powder in step (2), and the input quality of freeze-dried powder, calcium dihydrogen carbonate, sodium bicarb...

Embodiment 3

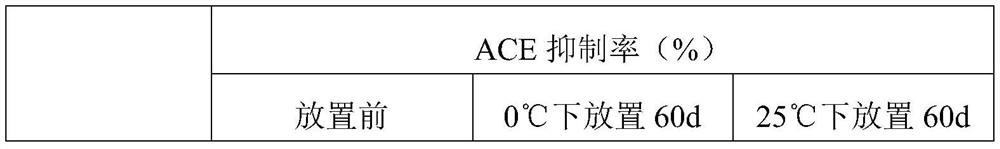

[0059] Embodiment 3: the influence of step (3) and step (5)

[0060] Test object: embodiment 1, control group 5-7.

[0061] Control group 5: with reference to Example 1, the difference from Example 1 is that the step (3) enzymatic hydrolysis step only includes the following part: adjust the pH of the dispersion to 7.8, heat up to 45 ° C, add trypsin, and stir to make it Enzymolysis, the enzymolysis time is 2.0hr, after enzymolysis, the temperature is raised to 100°C and kept for 15min to inactivate the enzyme; the mass ratio of dispersion liquid and trypsin is 100:0.5.

[0062] Control group 6: with reference to Example 1, the difference with Example 1 is that step (3) includes:

[0063] ① Adjust the pH of the dispersion to 7.0, raise the temperature to 52°C, add neutral protease, and stir to make it enzymolyze. The mass ratio of protease is 100:0.3;

[0064] ②Adjust the pH of the dispersion to 7.0, raise the temperature to 40°C, add lipase, stir for enzymolysis, the enzymo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com