Optical fiber temperature sensor

A fiber optic sensor and fiber optic temperature technology, applied in thermometers, thermometer parts, thermometers with physical/chemical changes, etc., can solve the problems of no fiber optic sensor protection measures, fiber optic sensor damage, and fiber optic sensor without effective protection. , to achieve the effect of convenient and fast movement, preventing data loss and preventing pipeline overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

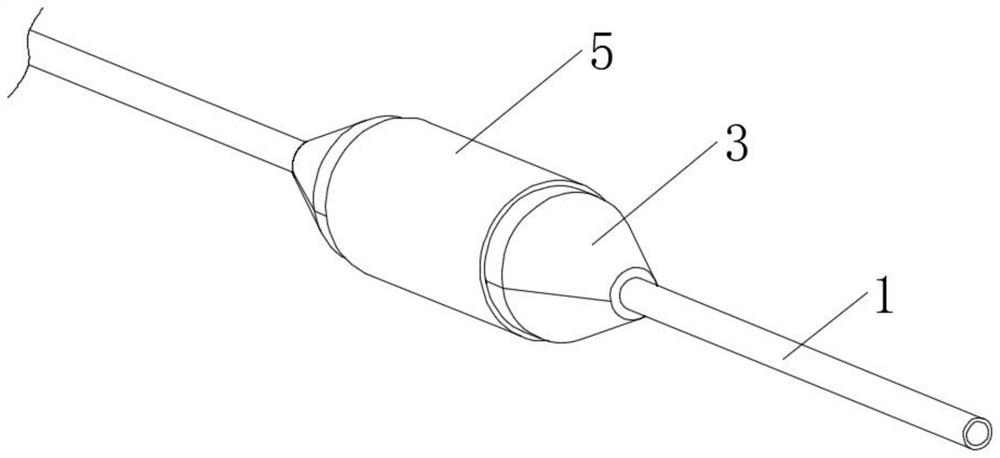

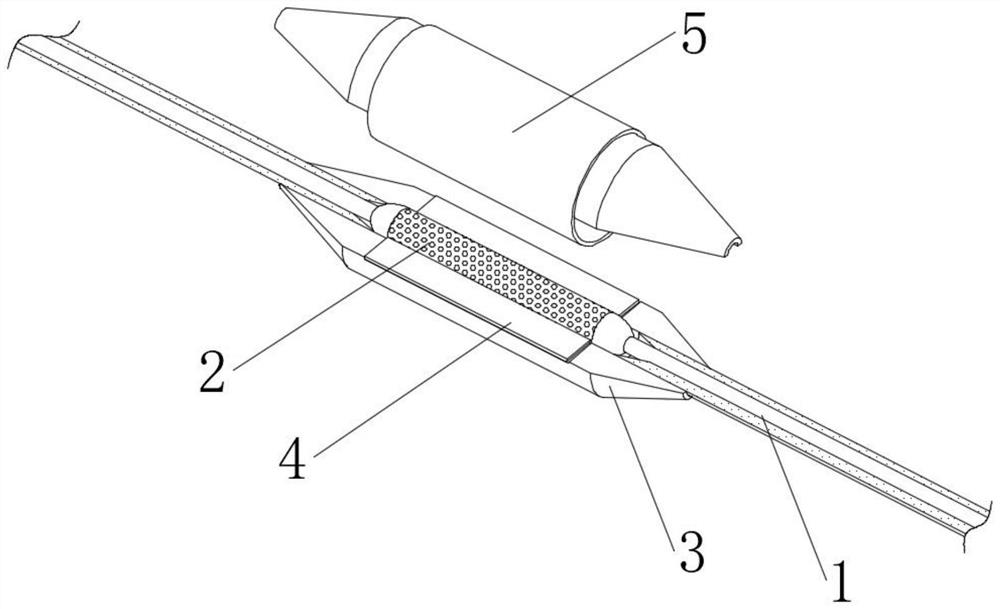

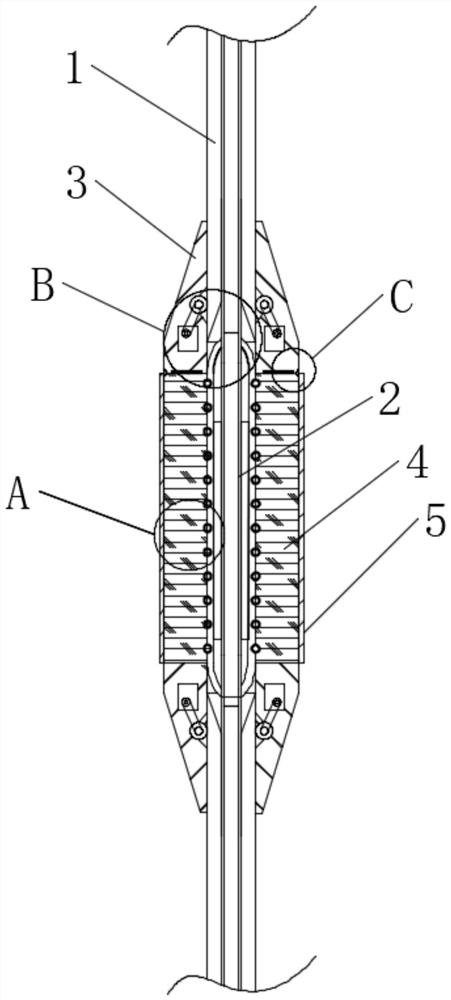

[0042] see Figure 1-6 , an optical fiber temperature sensor, comprising a multi-section pipeline main body 1, a plurality of detection sleeves 2 are fixedly connected to the pipeline main body 1, the detection sleeve 2 includes an optical fiber sensor main body 201, and sliding sleeves 202 are fixedly connected to both ends of the optical fiber sensor main body 201, The outer wall of the optical fiber sensor main body 201 is fixedly connected with an annular electric plate 203, and a pair of inspection posts 3 that are engaged with each other are provided on the outside of the detection sleeve 2. There is a rubber cone 302, and a guide wheel 303 is connected with the rotation in the rubber cone 302. A micro motor matching the guide wheel 303 is installed in the rubber cone 302, and a flexible rubber strip 304 is connected between the rubber cone 302 and the semicircular shell 301. One end of the cone 302 close to the semicircular shell 301 is fixedly connected with a magnet p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com