Electrolytic bath system and working method thereof

An electrolytic cell and working voltage technology, which is applied in the field of electrolytic cell systems, can solve the problems of large maintenance work and high cost of large alkaline electrolytic cells, and achieve the effects of reducing the amount of maintenance, saving maintenance costs, and facilitating positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

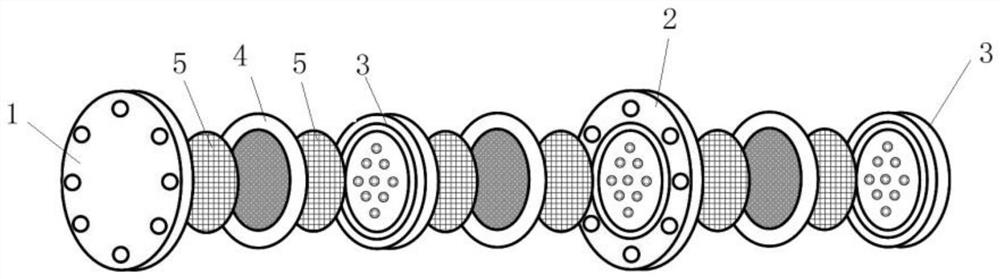

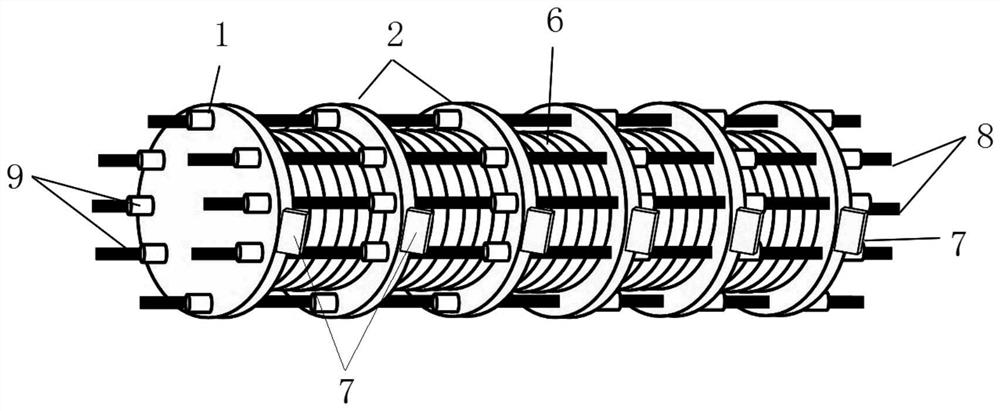

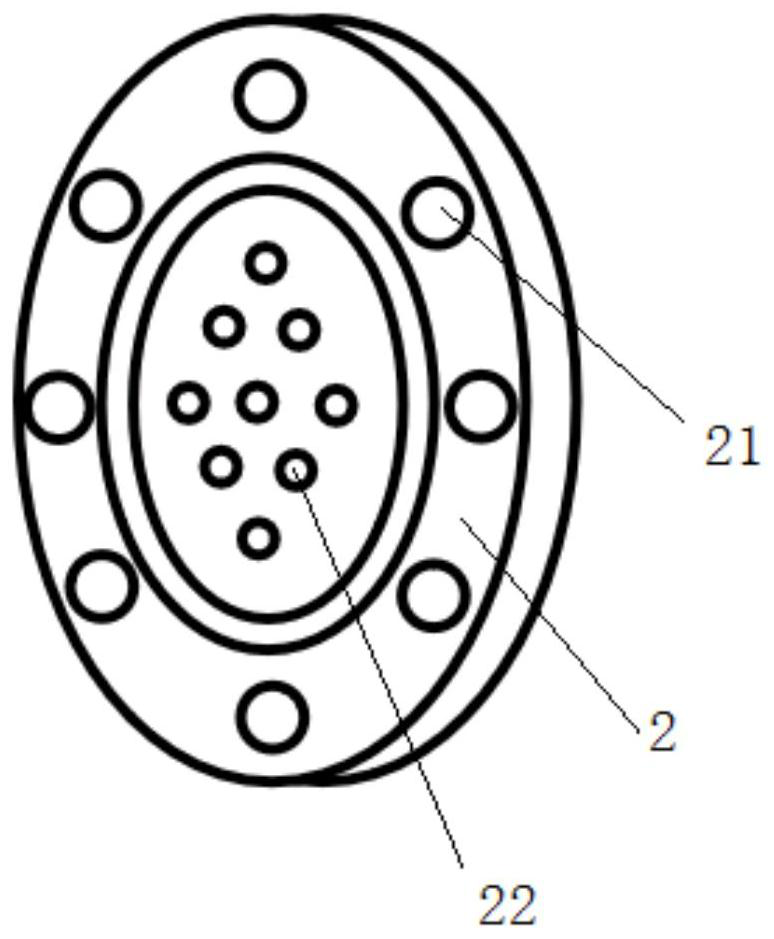

[0036] Such as figure 1 and 2 As shown, the present invention discloses an electrolytic cell system, which includes a multi-stage electrolytic cell, an acquisition module, a storage module and a first processing module; Between the multiple separator electrodes 2, the end plate electrode 1 is detachably connected to the multiple separator electrodes 2; there are electrolytic electrodes between the end plate electrode 1 and the separator electrodes 2 and between two adjacent separator electrodes 2. Unit 6, each electrolysis unit 6 forms a primary electrolyzer; Terminal posts 7 are installed on the end plate electrodes 1 and separator electrodes 2, and the terminal posts 7 are connected to the power supply, and the terminal posts 7 on one of the end plate electrodes 1 As the anode terminal, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com