Water jacket ascension pipe heat exchanger with heat insulation and storage layer and transformation method of water jacket ascension pipe heat exchanger

A technology of heat exchanger and heat storage layer, which is applied in the heating of coke ovens, the discharge device of dry distillation gas, and the petroleum industry. Reduce high-temperature oxidation and high-temperature creep, increase heat transfer efficiency, and reduce the effect of wall temperature transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

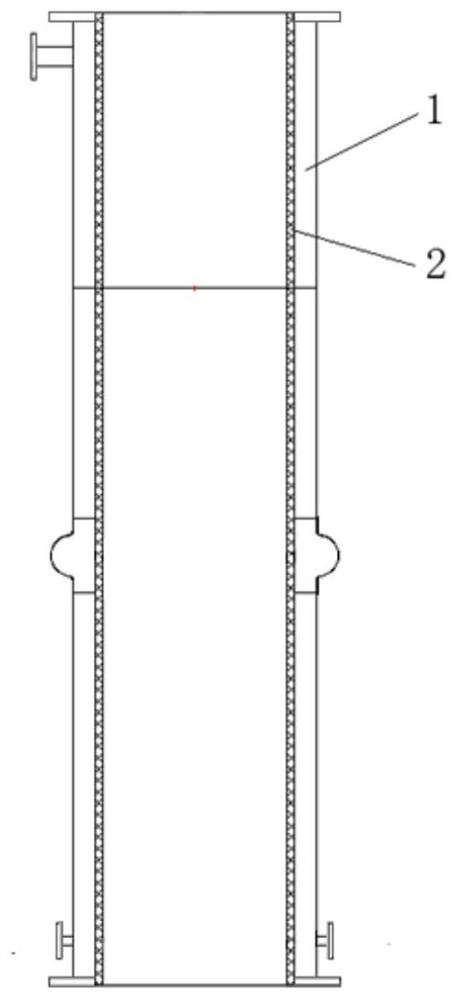

[0040] The turtle net 5 welded in the inner wall of the rising tube heat exchanger, and the tilt heat storage layer 2 is poured, and the heat storage heat storage layer 2 is attached to the inner wall of the rising tube heat exchanger 1. The turtle noodle 5 has a high temperature resistant to high-resistance, which can enhance the fixation effect of the insulation heat storage layer 2, making it more secure.

[0041] A transformation method of a rising tube heat exchanger, including the following steps:

[0042] a. Use a grinding wheel or sand blasting machine to grind the inner wall of the rising tube 1, leak the inner steel pipe;

[0043] b. Welded Turtle Net 5, in the rising tube heat exchanger inner wall welding turtle.com 5;

[0044] c. Rising tube heat exchanger 1 Press: The welded rising tube heat exchanger 1 is pressed according to the pressure on the requirements of the rising tube heat exchanger, and the pressure maintenance time is greater than 30 min;

[0045] Among th...

Embodiment 2

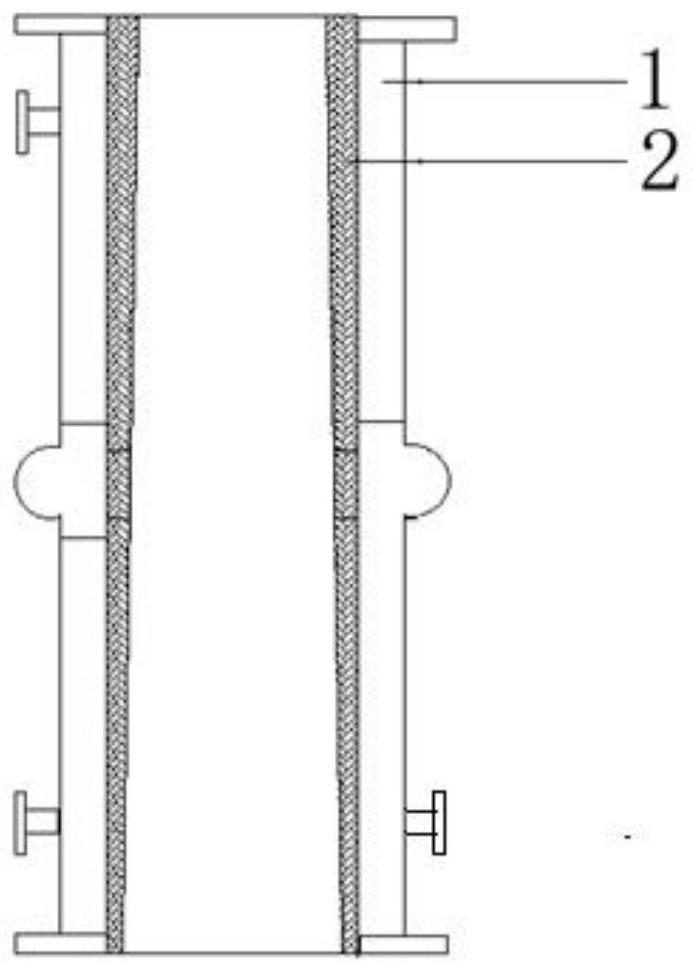

[0051] like Figure 3-4 , The inner wall of the rising tube heat exchanger a plurality of the inner wall of rivet welding, heat storage pouring insulation layer on the rivet, the insulating layer 2 against the heat storage of the riser; embodiment according to the present embodiment , the rivet is welded to a uniform shape of the inner wall of the riser pipe heat exchanger 1, to ensure uniform force, the rivet is a Y-type or T-shaped construction helps prevent heat accumulation layer rigid front insulating collapse the material shrinks uniformly, avoiding cracking.

[0052] The method of transformation of one kind of the riser pipe heat exchanger, comprising the steps of:

[0053] . A coke with a grinder or the blasting machine the riser inner wall of the heat exchanger 1 tar polished clean, leaking pipe wall;

[0054] . B rivet welding: the inner wall of the riser 1 uniformly heat welding said rivet;

[0055] . C suppress rising tube heat exchanger 1: The welded heat exchanger 1 o...

Embodiment 3

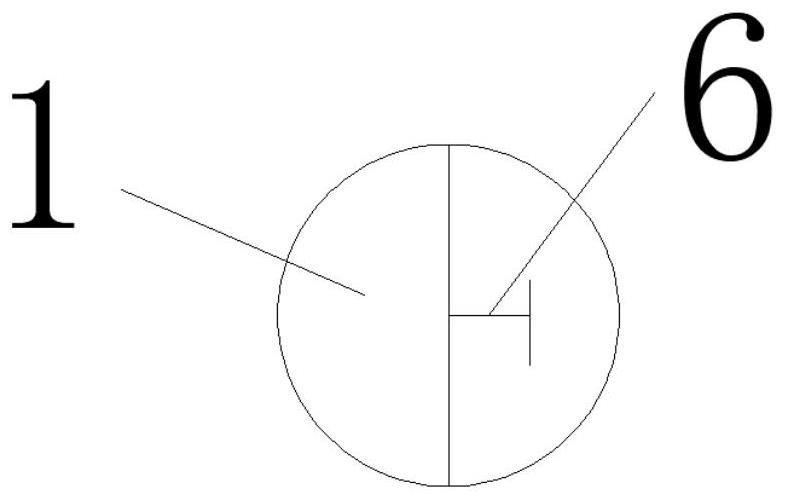

[0060] like Figure 5 Shown, the ascending upper, middle and lower average number of welded heat exchanger tube is fixed to the ring bars 3, and between the riser pipe and the middle heat exchanger to the fixed upper ribs, the central ring the lower ring is fixedly connected to the four ribs axially fixed between the fixing rib 34, a plurality of uniformly welded to rivet the riser pipe inner wall, the shape of the rivet is Y or T, hexagonal mesh 5 is mounted in the heat exchanger the mouth of said hoop-shaped holding ribs 3 and 4 of the axially fixed ribs consisting of 3, the ribs 4 is axially fixed, and the placing of the rivets 5 in the hexagonal mesh bars secured to said ring said thermal storage heat insulating layer 2 ,, the heat storage layer 2 against the inner wall of the riser tube heat exchanger 1.

[0061] Specifically, the fixed ring with axially fixed ribs 3 and ribs 4 Stainless steel bar, the riser inner wall of the heat exchanger 1 are welded one week four fixed ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com