Long and thin workpiece vertical conveying machine and system

A technology for slender workpieces and conveying machinery, which is applied in the directions of conveyors, conveyor objects, conveyor control devices, etc., can solve problems such as affecting product quality, reducing the quality of galvanized treatment, and adhering impurities on the surface, and achieves stability. , the structure is simple, the effect of reducing the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The object of the present invention is to provide a vertical conveying machine for slender workpieces, which is used for automatic clamping, vertical conveying and release of long slender workpieces, and keeps the slender workpieces in a stable vertical position during the conveying process. state.

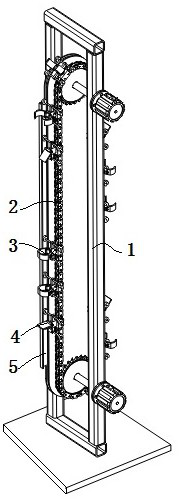

[0056] figure 1 , a schematic diagram of a three-dimensional structure of a vertical conveying machine for elongated workpieces provided by the present invention.

[0057] Such as figure 1 As shown, the overall technical solution of the present invention: a vertical conveying machine for elongated workpieces is provided, including a frame 1, a chain mechanism 2, a clamping mechanism 3, a guide mechanism 5 and a clamping control unit.

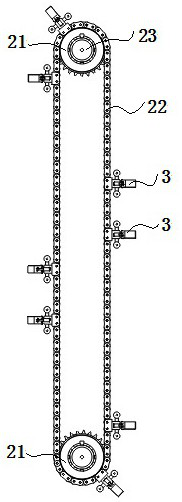

[0058] figure 2 , a structural schematic diagram of only the clamping mechanism being set on the chain.

[0059] Such as figure 2 As shown, the chain mechanism 2 plays the role of driving the clamping mechanism to move.

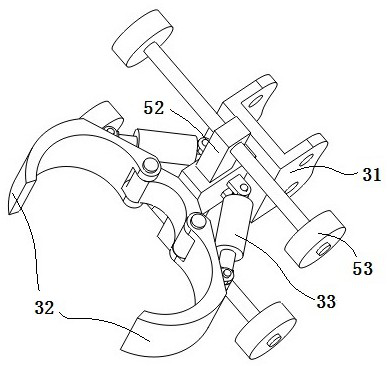

[0060] The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com