Plastic extrusion mold with high-heat-dissipation sizing sleeve

An extrusion die, high heat dissipation technology, applied in the field of plastic extrusion die, can solve the problems of single, can not achieve the shaping effect, cooling and shaping effect is not good, to reduce friction, improve shaping effect, improve cooling effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

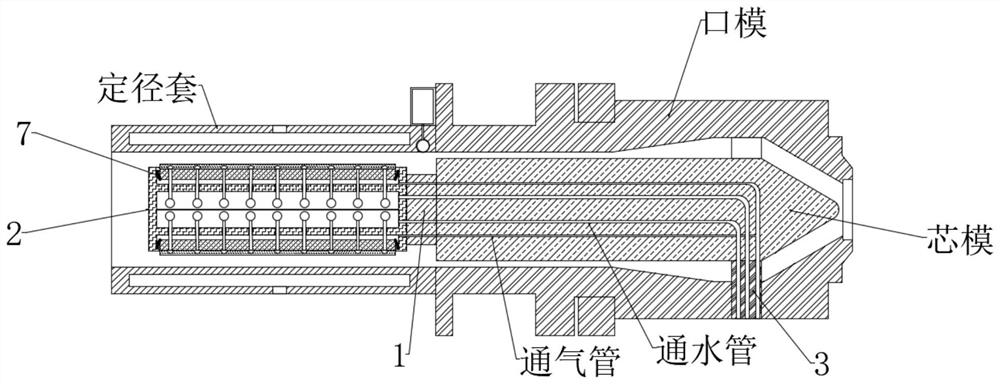

[0047] see Figure 1-10 , a plastic extrusion die with a high heat dissipation sizing sleeve, see Figure 1-3 , including the extrusion die body, the extrusion die body includes the machine head, the machine head includes an external die and an internal mandrel, one end of the die is fixedly connected with a sizing sleeve, and the inside of the sizing sleeve is provided with cooling and shaping auxiliary parts 2. A connecting seat 1 is fixedly connected between the cooling and shaping auxiliary part 2 and the core mold. The end of the core mold away from the cooling and shaping auxiliary part 2 is connected with an access valve 3. The core mold and the connecting seat 1 are provided with an access valve. The air pipe and the water pipe connected by the valve 3, and the air pipe and the water pipe are all connected with the cooling and shaping auxiliary part 2, and the inside of the access valve 3 is provided with two water inlet passages and the water passage 301 connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com