Hardware base splicing, welding and galvanizing all-in-one machine for mechanical equipment

A technology of mechanical equipment and all-in-one machine, which is applied in the field of tailor-welded and galvanized all-in-one machines for hardware bases, can solve the problems of inability to quickly perform anti-rust treatment, poor consistency of finished product specifications, inconsistent installation holes, etc., and achieve good synchronous movement effect and verticality. Good, consistent relative angle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

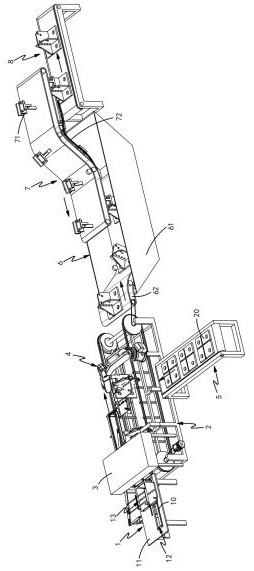

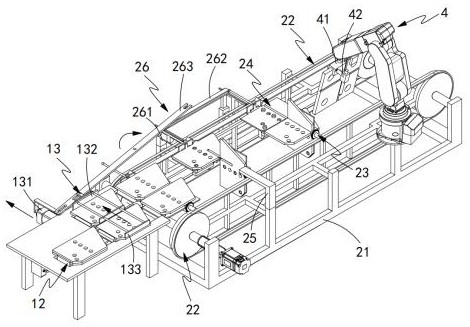

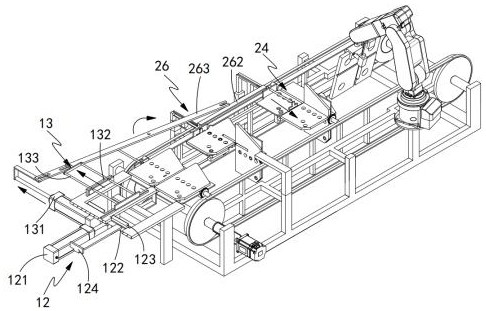

[0068] Such as figure 1 , 2 , 3 and 15, a metal base tailor welding and galvanizing integrated machine for mechanical equipment, including a feeding mechanism and a slotting mechanism 3, is characterized in that it also includes:

[0069] Flatten body 2;

[0070] finished product gripping device 7; and

[0071] Finished product conveyor line 8;

[0072] The feeding mechanism provides a vertical plate 10 and a horizontal plate 20 to the splicing mechanism 2, and the splicing mechanism 2 splices and welds two vertical plates 10 and a horizontal plate 20 into a whole;

[0073] The finished product grabbing device 7 is in transmission connection with the splicing mechanism 2, and the finished product grabbing device 7 grabs the welded finished product for galvanizing and then transfers it to the finished product conveying line 8 for output.

[0074] Further, the feeding mechanism includes:

[0075] Riser Feed Group 1; and

[0076] Horizontal plate feeding group 5;

[0077] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com