Rapid positioning and welding equipment for hardware accessories

A technology of positioning welding and accessories, which is applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of difficulty in ensuring the verticality of the vertical plate, poor consistency of finished product specifications, etc., and achieve good synchronous movement effect and verticality Good, the effect of maintaining a certain distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

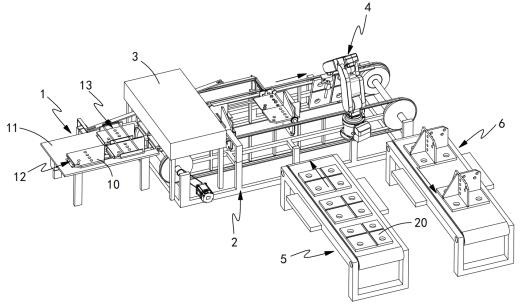

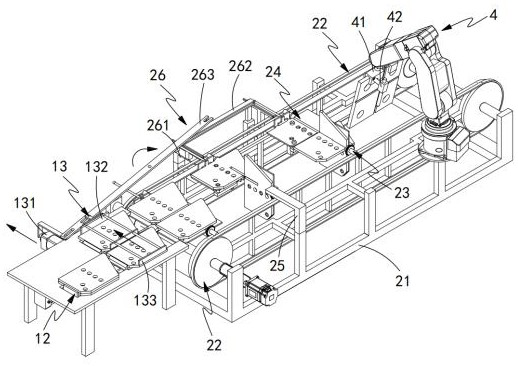

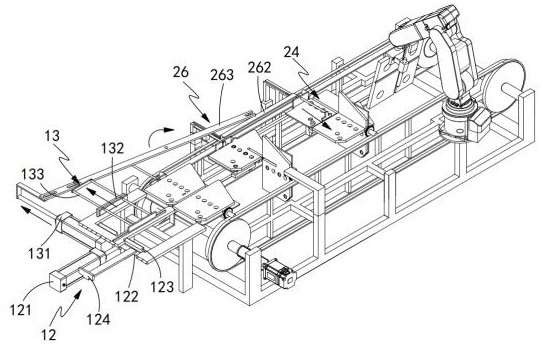

[0058] Such as Figures 1 to 3 As shown, a rapid positioning welding equipment for hardware accessories includes a vertical plate feeding device 1, an assembly conveying device 2, a cutting machine 3, a welding transfer device 4, a bottom plate conveying line 5 and a finished product conveying line 6, the vertical plate The feeding device 1 is arranged at the head end of the conveying direction of the assembling conveying device 2, the slitting machine 3 is erected above the assembling conveying device 2, and the welding transfer device 4 is arranged on the conveying direction of the assembling conveying device 2. direction, the bottom plate conveying line 5, the finished product conveying line 6 and the assembled conveying device 2 are surrounded by the welding transfer device 4 as the center;

[0059] Described vertical panel feeding device 1 comprises workbench 11, feed pushing assembly 12 and board-splitting assembly 13, and described workbench 11 is provided with stand-by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com